CNC Machining in Bangalore

- Get Instant Quotes instantaneously

- Reach tight tolerance of up to 20 microns

- Over 2000 machines to increase your production

- Varying Applications through the machining of distinct materials

Trusted by more than 10,000 engineers and procurement leaders

Secure Quotes And Acquire Your Machine Parts Instantaneously On Order

Zeometrix is your one-stop for all manufacturing services. Get instantaneous quotes on machine parts with our services. With a strong network of suppliers, we provide custom CNC machining services to its diverse base of clients. We specialize in CNC Machining in Bangalore catering to a wide range of precision manufacturing needs. Start the process by submitting 3D files, relevant part drawings, or other information. Rest assured our dedicated professionals will process your submission and supply you with a quote at the earliest. Zeometrix has an ISO 9001: 2015 certified quality management system that makes sure that the quality of your machine parts is the best.

Advantages of Ordering CNC Machined Parts from Zeometrix

Instantaneous Quoting

Quickly get quotes on custom machine parts with Zeometrix’s CNC Machining Services. Submit your form with relevant pieces of information and get top-quality quotes created by our team of professionals at the earliest.

High Quality Products

Zeometrix has an ISO 9001:2015 certified quality management system making sure that the clients get exceptional craftsmanship Of machined parts that exceed expectations.

Enormous Network Capacity

Instantly get access to our diverse manufacturing and supply network catering to different client bases and get top-quality CNC Machining services.

Explicit Pricing Structure

Zeometrix’s pricing structure ensures that there are no hindrances in your project planning and that the entire project of the client is executed effectively.

Where does it come from

Rapid Tooling

This fast process of CNC machining is used for creating molds and tools that can instantaneously produce prototypes and custom parts saving both cost and time. It reduces the lead time taken and develops more precise tools using advanced technologies.

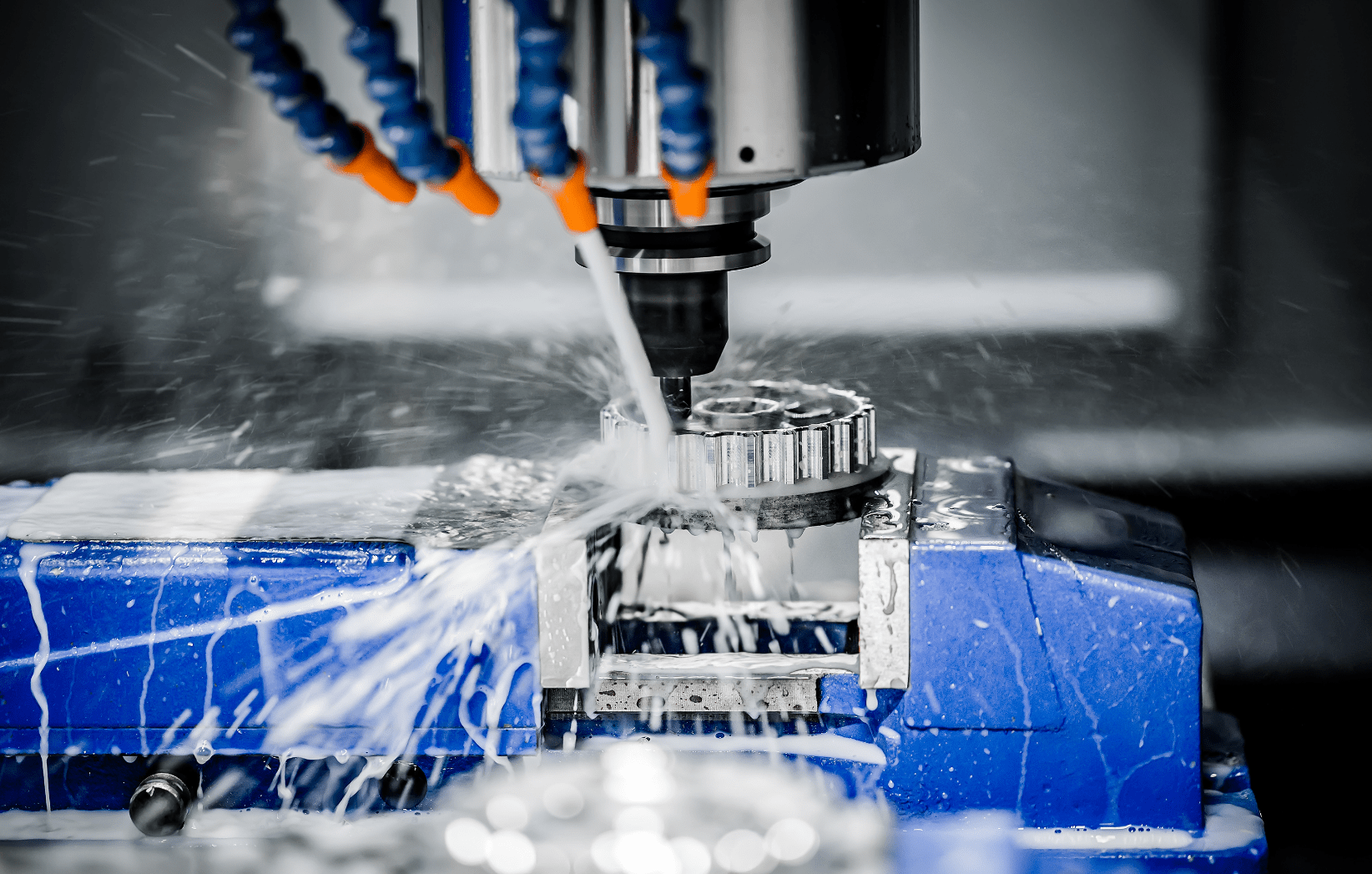

Rapid Prototyping

This method uses computerized equipment to instantaneously produce parts using complex geometries and a much higher accuracy. The biggest advantage of Rapid Prototyping is its ability to produce complex parts cost-effectively.

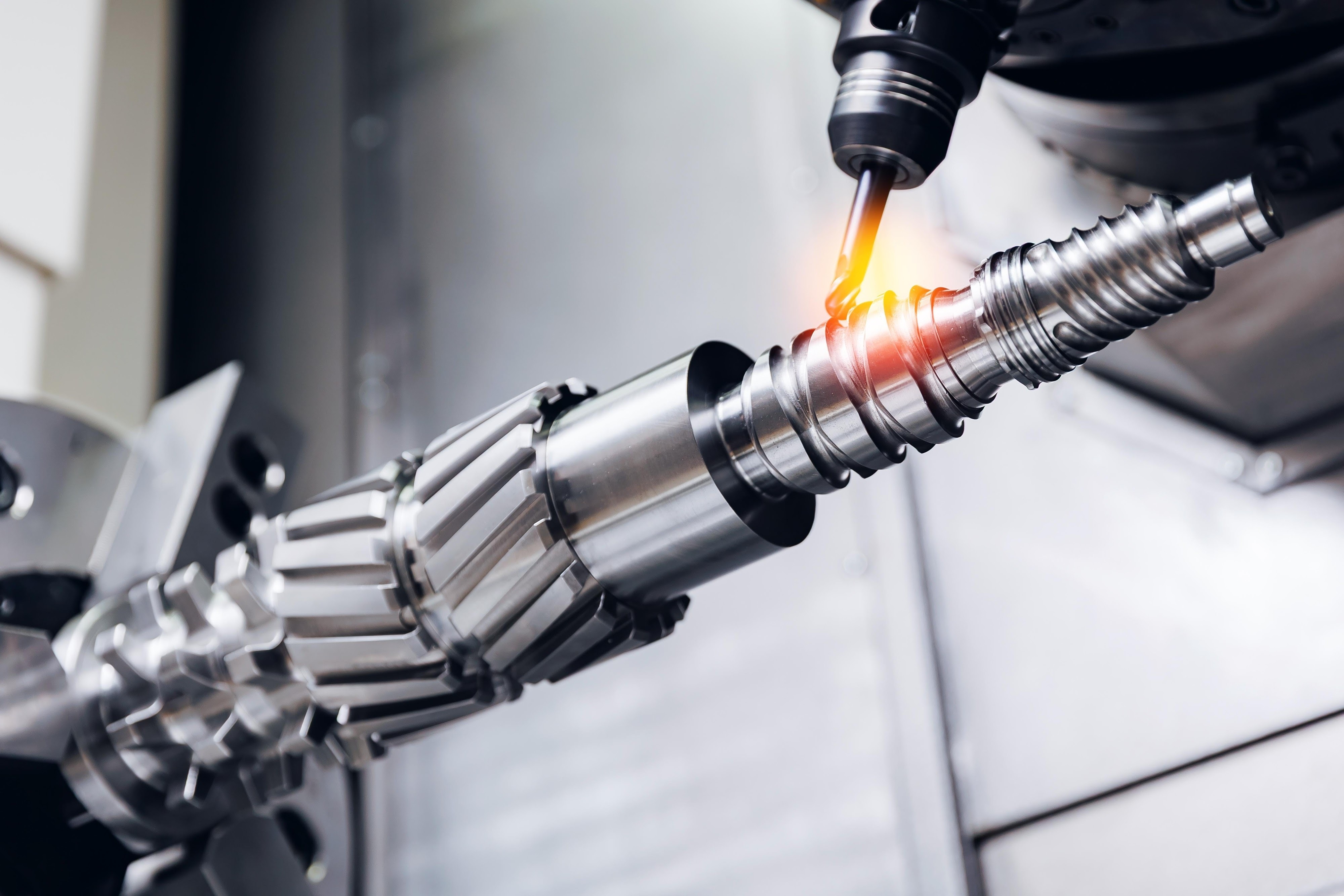

End-Use Production

The high precision and improved performance finishing backed by its certifiable material choices of CNC Machining makes it the best choice for developing end-use parts in multiple industries such as Aerospace, Automotive, and many more.

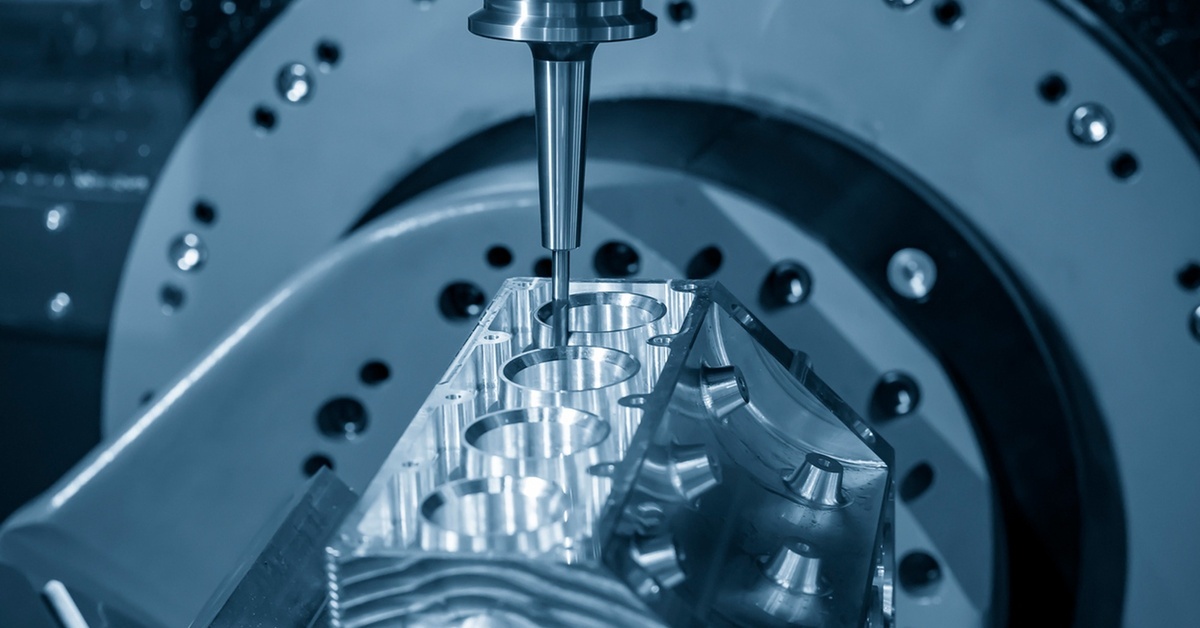

5-Axis Machining

This method allows for the constant movement of a tool in the 5 different axes giving more elasticity and accuracy. This process can work on difficult geometries and complicated shapes which was quite difficult in the 3-axis machining.

Examples of Our CNC Work

Custom CNC Milling: Tailored Solutions for Any Project

By Orjo Bora

06-11-2024

High-Speed CNC Turning: Efficient Production with Quality

By Orjo Bora

06-11-2024

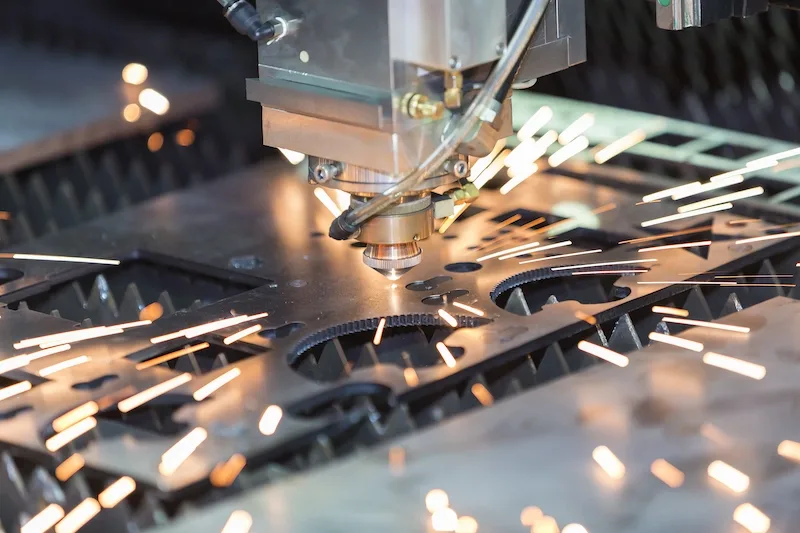

What materials can be cut with laser cutting?

By Orjo Bora

08-11-2024

How CNC Machining is Revolutionizing Production in Bangalore

By Orjo Bora

13-06-2025

Top 7 Advantages of Production CNC Machining for High-Volume Parts

By Orjo Bora

06-02-2025

The Role of CNC Machining in Bangalore’s Industrial Automation Growth

By Orjo Bora

28-06-2025

What Is Production CNC Machining? A Comprehensive Guide

By Orjo Bora

04-07-2025

What Is CNC Machining Prototyping? Everything You Need to Know

By Orjo Bora

07-10-2025

Affordable and High-Quality CNC Machine Manufacturers in India

By Orjo Bora

19-07-2025

Affordable CNC Machine Manufacturers in Bangalore for Every Industry

By Orjo Bora

25-07-2025

How Zeometrix Delivers CNC Parts with 20-Micron Accuracy

By Orjo Bora

02-08-2025

5 Ways Zeometrix Streamlines Your Manufacturing with Instant Quotes

By Orjo Bora

08-08-2025

Advanced CNC Machining Services | Milling, Turning & Drilling

By Orjo Bora

16-08-2025

ISO-Certified CNC Machining Services in Bangalore: Zeometrix’s Quality Edge

By Orjo Bora

22-08-2025

CNC Machining in Bangalore Driving Automotive Innovation

By Orjo Bora

30-08-2025

Instant Quotes and Rapid Prototyping: Zeometrix CNC Machining Advantage

By Orjo Bora

05-09-2025

Advantages of CNC Machining Over Traditional Manufacturing in Bangalore

By Orjo Bora

13-09-2025

Beyond the Blueprint: How Zeometrix's CNC Machining Brings Ideas to Life in Bangalore

By Orjo Bora

19-09-2025

Is Investing in a CNC Machine in Banglore Worth It for Your Business?

By Orjo Bora

26-09-2025

Top CNC Machining Services in Bangalore for Precision Engineering

By Zeometrix

02-10-2025

Why CNC Machining Services in Bangalore Are in High Demand

By Zeometrix

03-10-2025

Top CNC Machine Manufacturers in Bangalore – The Ultimate Comparison Guide

By Zeometrix

09-10-2025

Leading CNC Machine Manufacturers in Bangalore for Advanced Manufacturing

By Zeometrix

11-10-2025

CNC Machining in Bangalore | Precision Engineering & On-Time Delivery

By zeometrix

25-10-2025

Everything You Need to Know About CNC Machining in Bangalore

By zeometrix

28-10-2025

Trusted by 10,000+ Engineers: Unmatched CNC Machining in Bangalore Quality and Capacity

By Zeometrix

06-11-2025

From Concept to Component: Reliable CNC Machining Solutions in Bangalore

By Zeometrix

13-11-2025

10+ Years of Excellence: Zeometrix – The Experienced CNC Company in Bangalore

By Zeometrix

26-11-2025

The CNC Hub: Choosing the Right Advanced Manufacturing Partner in Bangalore

By Zeometrix

05-12-2025

Engineering Precision at Every Step: Why Zeometrix Is a Trusted CNC Partner in Bangalore

By Zeometrix

18-12-2025

Crafting the Future: The Intersection of Software, Hardware, and CNC Machining in Bangalore

By Zeometrix

24-12-2025

The Ultimate Guide to CNC Machining in Bangalore: Precision Engineering with Zeometrix

By Zeometrix

01-01-2026

Engineering at Micron Precision: Zeometrix and the Rise of Advanced CNC Machining in Bangalore

By Zeometrix

08-01-2026

Smart Factories, Smarter Machining: The Evolution of CNC Manufacturing in Bangalore

By Zeometrix

14-01-2026

How a CNC Company in Bangalore Is Powering the Next Wave of Advanced Manufacturing

By Zeometrix

20-01-2026

Bangalore CNC Manufacturers Explained: Capabilities, Standards, and the Future

By Zeometrix

29-01-2026

CNC Machining Materials

-

Q1) What do you mean by CNC/VMC machining?

It is a flexible process that converts raw materials such as finished shapes, bars, or cylindrical stocks into finished products of multiple geometries and sizes. With the ability of accurate tolerance, it allows the production of both small and large parts.

-

Q2) How do CNC machines work?

CNC machines are known to use software that has been pre-programmed to do a variety of machining tasks that include shaping, cutting, and building parts. It can be summed up in two steps:- Step 1:- The programmer writes the codes telling the machine how to perform the task Step 2:- The motors of the machine will convert the programmed sequence into movements and carry out the task.

-

Q3) What separates CNC and Traditional Machining?

Traditional machining depends on Manual labor to carry out tasks taking up more than the required time and money while CNC machining depends on skilled employees with technical expertise to save time and money.

-

Q4) Name some prominent Industries that use CNC Machining.

CNC machines are applied throughout the world in many different fields such as aerospace, robotics, automotive, agriculture, consumer electronics, and many other fields, making it the most recurrently used manufacturing process.

-

Q5) What materials are used by Zeometrix to create machine parts?

Zeometrix can use its machining processes on a wide range of materials. Some of the materials are:- Copper Aluminium Acrylic Nylon Delrin Stainless Steel PTFE (Teflon) Polycarbonate