Bangalore CNC Manufacturers Explained: Capabilities, Standards, and the Future

The skyline of Bangalore is often defined by the shimmering glass towers of IT parks, but the city’s true industrial heart beats in the rhythmic hum of spindles and the cooling spray of lathes. Known globally as the "Silicon Valley of India," Bangalore has firmly established itself as the nation’s premier hub for high-precision manufacturing. For any enterprise—be it a global aerospace giant or a burgeoning medical tech startup—the search for CNC machine manufacturers in Bangalore is a search for quality, reliability, and technical sophistication.

In this competitive landscape, Zeometrix has emerged as a beacon of excellence. By bridging the gap between traditional machining and modern "Industry 4.0" practices, Zeometrix isn't just manufacturing parts; they are engineering the future of Indian industry. This blog provides a deep-dive into the Bangalore CNC ecosystem, the technologies driving the sector in 2026, and why Zeometrix is the partner of choice for precision-critical projects.

1. The Historical Evolution of Bangalore’s Machining Sector

To appreciate the current state of CNC machine manufacturers in Bangalore, one must look back at the city’s industrial roots. Unlike other manufacturing hubs in India that focused on textiles or heavy metals, Bangalore’s industrial growth was driven by precision from the very beginning.

The PSU Legacy

The foundation was laid in the 1950s and 60s with the establishment of Public Sector Undertakings (PSUs) like Hindustan Aeronautics Limited (HAL), Bharat Electronics Limited (BEL), and HMT Machine Tools. These organizations required components with tolerances that were unheard of in traditional manufacturing. This demand birthed a massive ecosystem of specialized small and medium enterprises (SMEs) in industrial areas like Peenya, which is today one of the largest industrial clusters in Southeast Asia.

The Shift to CNC

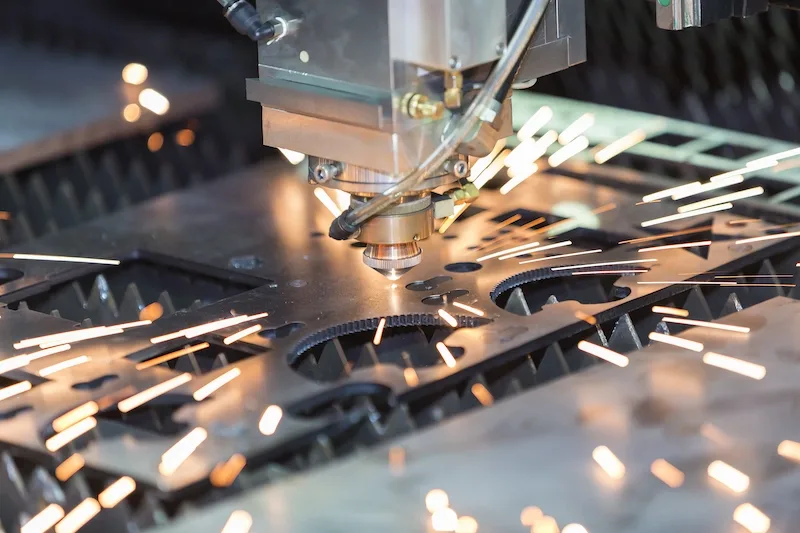

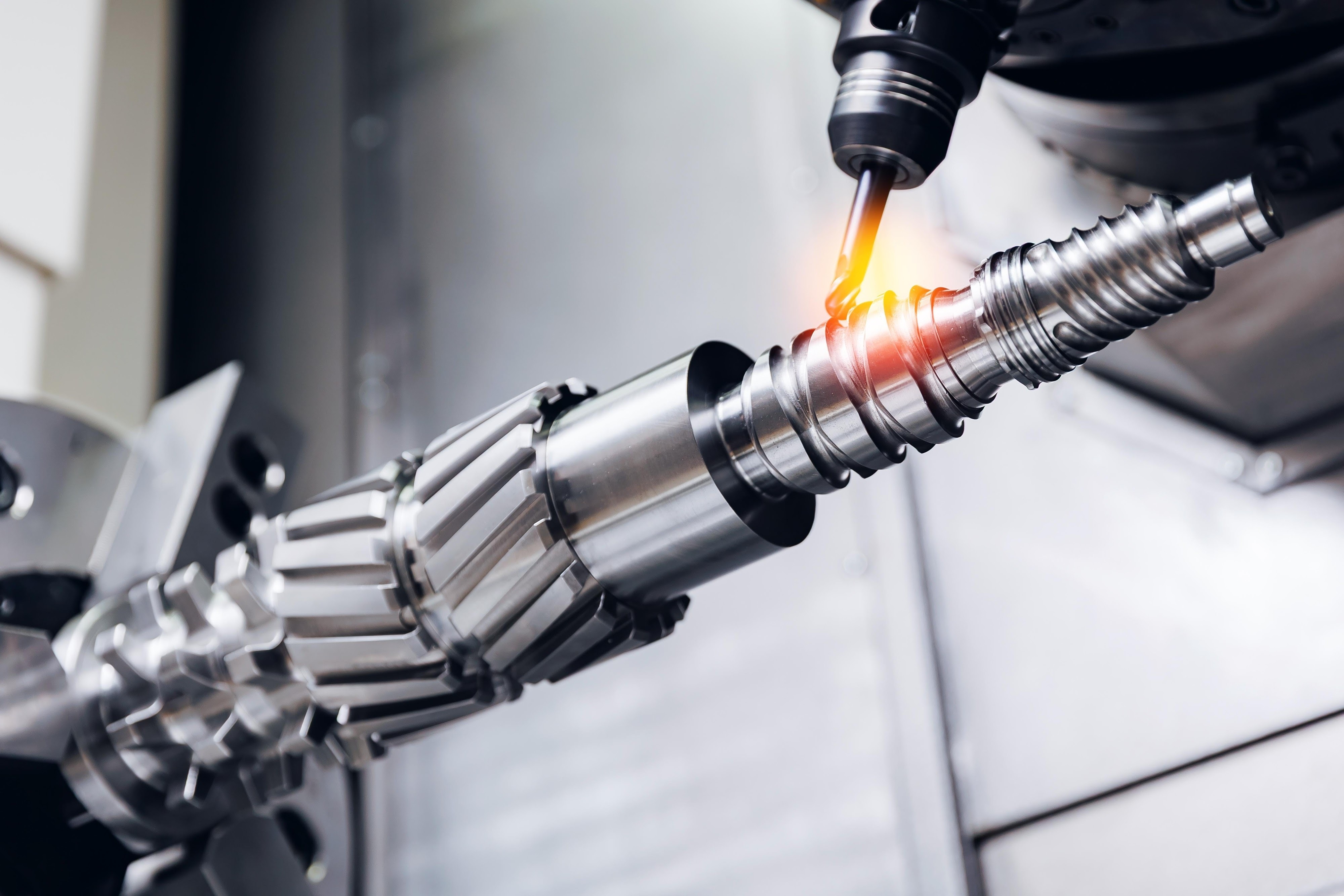

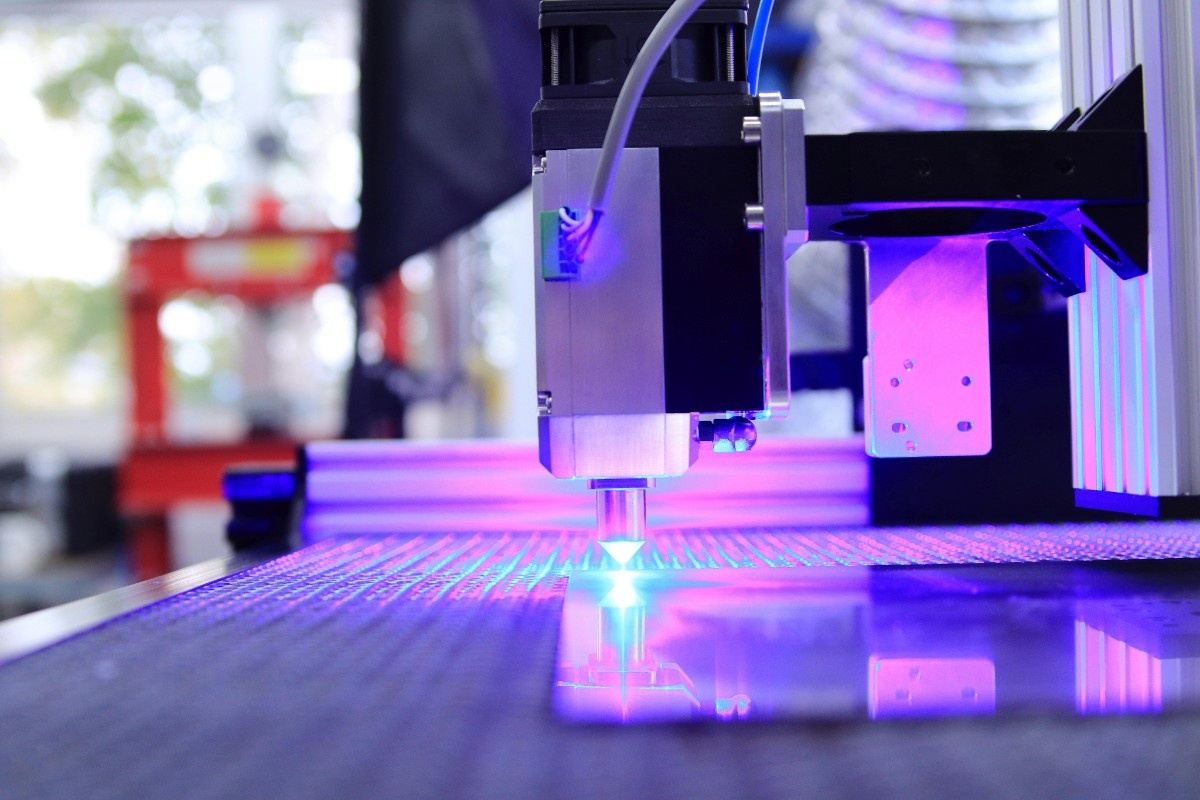

By the late 1990s and early 2000s, manual machining began giving way to Computer Numerical Control (CNC). Bangalore’s workforce, already comfortable with software and technical logic, adapted faster than any other region. Today, in 2026, the city’s manufacturers have moved beyond basic 3-axis milling into complex 5-axis simultaneous machining, wire EDM, and hybrid additive-subtractive manufacturing.

2. Why Bangalore is the Preferred Destination for Global Sourcing

When global procurement officers look for CNC machine manufacturers in Bangalore, they aren't just looking for lower labor costs. They are looking for an "ecosystem advantage" that provides a 360-degree solution.

Proximity to Key Industries

Bangalore is the headquarters for the Indian Space Research Organisation (ISRO) and several major defense contractors. This proximity means that local manufacturers like Zeometrix are accustomed to "Mission Critical" standards. When a company produces a part in this city, it is often with the understanding that the component might end up in a satellite or a life-saving surgical tool.

Integrated Supply Chain

In Bangalore, you don't just find machining. Within a 20-kilometer radius, you have access to:

-

Heat Treatment Specialists: Essential for hardening aerospace and automotive parts.

-

Surface Finishers: Experts in anodizing, chrome plating, and PVD coating.

-

Material Science Labs: Facilities to verify the chemical and physical properties of alloys.

This integrated nature reduces lead times and ensures that the final product is ready for assembly the moment it leaves the shop floor.

3. Zeometrix: Redefining Manufacturing Partnerships

Among the myriad of CNC machine manufacturers in Bangalore, Zeometrix stands out because of its philosophy: Precision is a habit, not an accident.

Engineering First, Machining Second

Most shops take a drawing and hit "start." Zeometrix begins with a Design for Manufacturability (DFM) review. Their engineers analyze the client’s CAD files to see if a part can be made more efficiently. Could a radius be changed to allow for a larger, faster tool? Can a setup be combined to reduce error? This consultative approach often saves clients 15-20% in production costs before a single chip is cut.

Advanced Multi-Axis Capabilities

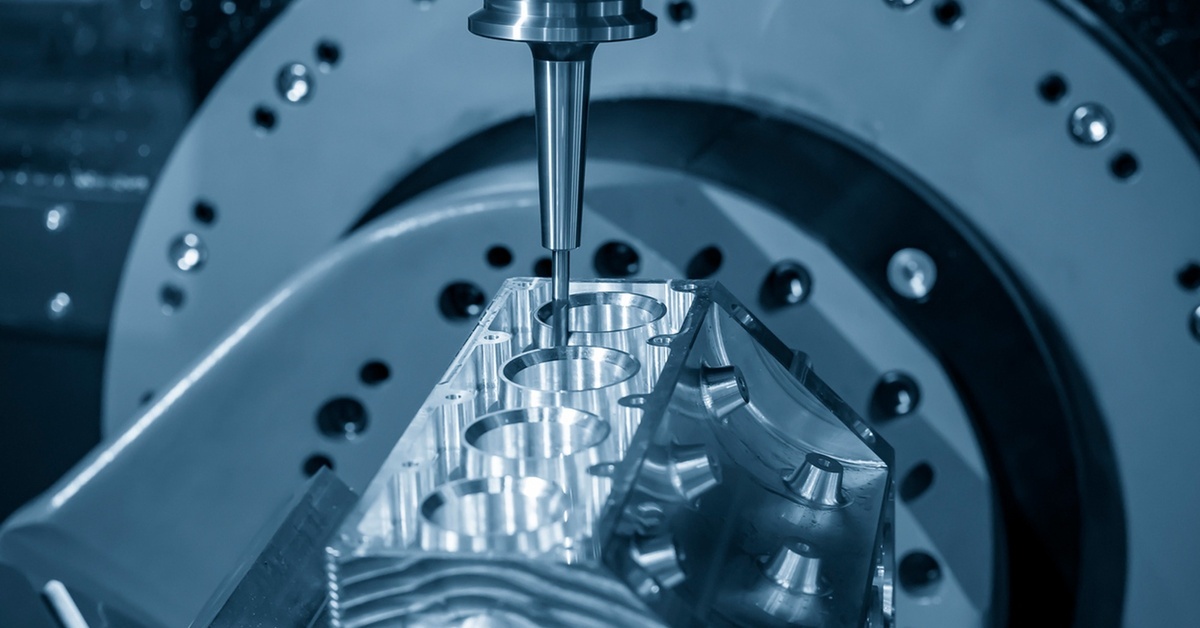

In the modern era, complexity is the norm. Zeometrix has invested heavily in 5-axis CNC machining. Unlike 3-axis machines that move in X, Y, and Z planes, 5-axis machines allow the tool or the part to rotate on two additional axes.

-

Benefits: This allows for the machining of complex "undercut" geometries and reduces the need for multiple setups. Fewer setups mean fewer opportunities for human error and much tighter tolerances.

Material Mastery

Modern engineering demands more than just aluminum and steel. Zeometrix specializes in:

-

Titanium (Grade 5): Essential for medical implants and aerospace.

-

Inconel & Superalloys: Used in high-heat environments like jet engines.

-

Engineering Plastics: Such as PEEK and Delrin for electrical and medical applications.

4. The Role of Industry 4.0 in 2026

As we navigate through 2026, the definition of a "good" manufacturer has changed. It is no longer enough to have a precise machine; you must have a "smart" machine. CNC machine manufacturers in Bangalore like Zeometrix are leading this digital transformation.

AI-Driven Quality Assurance

At Zeometrix, AI is a tool for predictive success. Modern CNC controllers now use machine learning to predict tool wear. By analyzing the acoustic signature and vibration of a cutting tool, the system can alert the operator to change a tool before it breaks or damages the part. This ensures that every part in a 1,000-unit batch is identical to the first.

Digital Twins and Virtual Commissioning

Before expensive blocks of Titanium are loaded into a machine, Zeometrix runs a Digital Twin simulation. This virtual model of the machine tool, the fixture, and the part allows for "collision checking."

It ensures that the tool path is optimized for speed and that there is zero risk of damaging the equipment or the workpiece.

IoT and Real-Time Tracking

Transparency is key for modern clients. Through IoT integration, Zeometrix can provide clients with real-time updates on their production status. This level of data integration helps in just-in-time (JIT) manufacturing, where parts arrive at the assembly line exactly when they are needed.

5. Sustainability: The New Frontier in Bangalore’s Factories

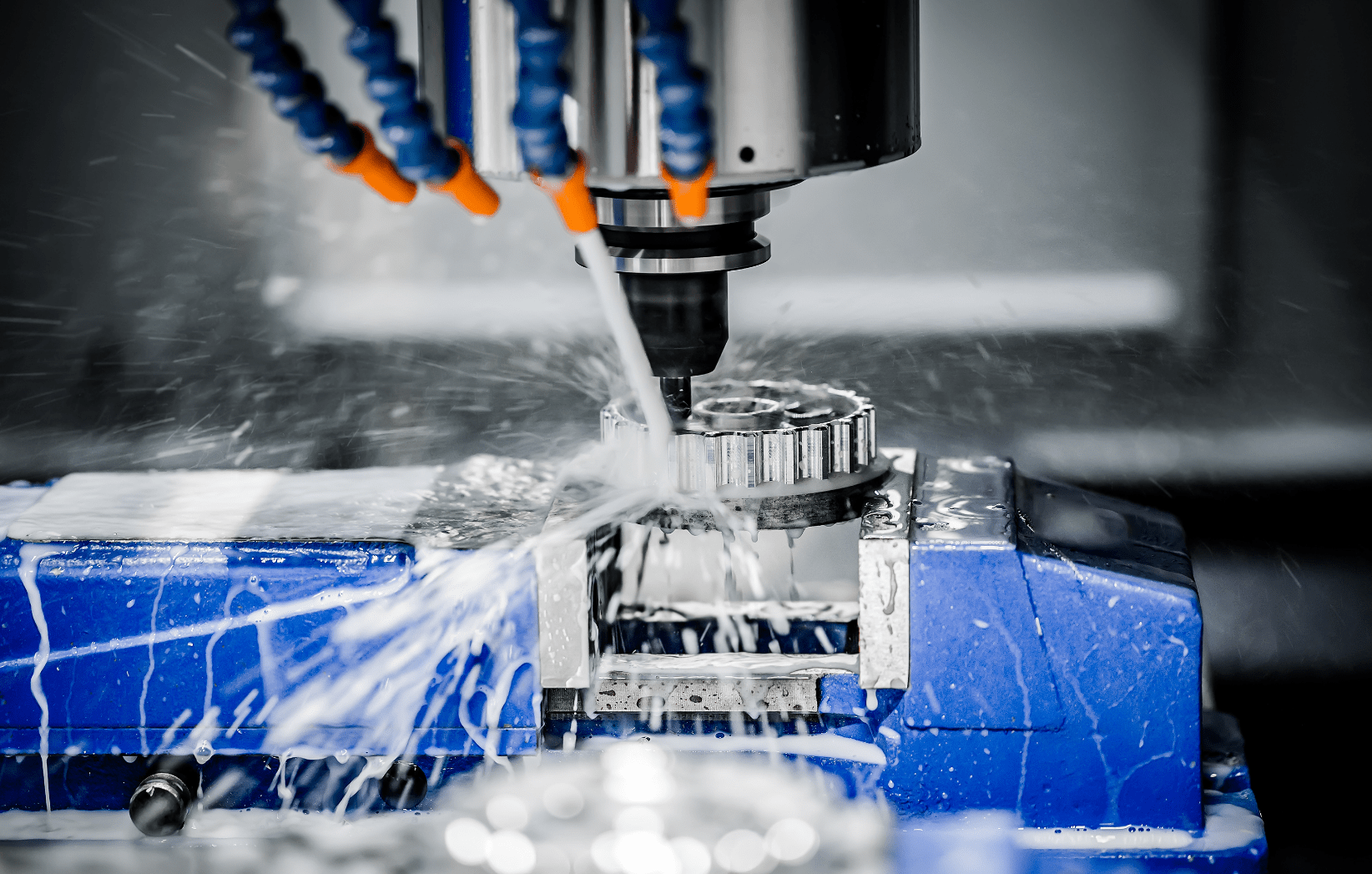

In 2026, “Green Manufacturing” is a prerequisite for doing business with European and North American markets. Bangalore’s leading manufacturers offering CNC machining services are making significant strides here:

-

Coolant Recycling: Advanced centrifugal systems separate metal chips from coolants, allowing the fluids to be reused and the metal to be sent for high-grade recycling.

-

Energy Efficiency: Transitioning to servo-driven motors in CNC machines, which consume up to 30% less power than older hydraulic systems.

-

Minimum Quantity Lubrication (MQL): Zeometrix utilizes MQL for specific materials, replacing "flood coolant" with a high-pressure oil mist, which is better for the environment and the operator.

6. Comparing the Top CNC Manufacturers in Bangalore

While Zeometrix is a leader in custom, high-precision work, it’s helpful to understand the different "players" in the Bangalore market to see where everyone fits.

|

Manufacturer |

Core Strength |

Ideal For |

|

Zeometrix |

Custom High-Precision & DFM |

Aerospace, Medical, R&D Prototypes |

|

Ace Designers |

High-Volume Turning |

Automotive, Fasteners, General Parts |

|

BFW |

Large Scale VMC/HMC |

Heavy Engineering, Railways, Energy |

|

HMT |

Large Industrial Units |

Government, Defense, Infrastructure |

|

Jyoti CNC |

Multi-tasking Machines |

Complex Industrial Components |

7. A Buyer's Checklist for CNC Services in Bangalore

If you are currently evaluating CNC machine manufacturers in Bangalore, use this checklist to ensure you are getting world-class service:

-

Certification Check: Ensure they hold ISO 9001:2015. If you are in aerospace, AS9100 is mandatory.

-

Metrology Equipment: Does the facility have a CMM (Coordinate Measuring Machine)? Without a CMM, verifying 3D tolerances is nearly impossible.

-

Tooling Quality: Ask what brands of cutting tools they use. High-end tools from companies like Sandvik or Kennametal result in better surface finishes.

-

Software Integration: Do they use modern CAM software like Mastercam or Hypermill? This dictates the complexity of parts they can handle.

-

Confidentiality: For R&D projects, ensure the manufacturer has robust Non-Disclosure Agreement (NDA) processes in place.

8. Why Zeometrix is Your Strategic Manufacturing Partner

Choosing Zeometrix is about more than just buying machine time; it is about securing your supply chain.

Scalability and Agility

Many shops in Bangalore are either "too small" to handle big orders or "too big" to care about small prototypes. Zeometrix occupies the sweet spot. They have the agility to produce a single, one-off prototype for a startup and the infrastructure to scale that to a monthly production run of thousands. This flexibility is vital in an era where product lifecycles are shrinking.

Transparency and Communication

In an industry often plagued by "delivery delays," Zeometrix prides itself on clear communication. Their project management systems ensure that you are never in the dark about where your parts are in the production cycle. By providing frequent updates and sticking to agreed timelines, they have built long-term trust with global clients.

Prototyping and Beyond

The journey from a digital file to a physical part is fraught with challenges. Zeometrix acts as a bridge. By offering rapid prototyping services, they allow engineers to test and fail fast, refining their designs before committing to expensive production tooling. Once the design is finalized, the same team manages the transition to mass production, ensuring that the "lessons learned" in prototyping are not lost.

9. The Future of CNC: Beyond 2026

As we look toward the next decade, the convergence of Additive Manufacturing (3D Printing) and Subtractive Manufacturing (CNC) is inevitable. Hybrid machines that can add metal and then immediately mill it to precision are the next frontier. Zeometrix is already exploring these hybrid workflows, ensuring that their clients are always at the cutting edge of manufacturing technology.

Furthermore, the rise of "Lights-out Manufacturing"—where machines run autonomously overnight without human intervention—is becoming the norm in Bangalore's high-end shops. This maximizes machine uptime and significantly reduces the cost per part, making Bangalore even more competitive on the global stage.

Conclusion

The evolution of CNC machine manufacturers in Bangalore is a success story of Indian grit and technical brilliance. As the city continues to solidify its position on the global map, companies like Zeometrix are leading the charge by offering world-class precision, ethical manufacturing practices, and cutting-edge technology.

Whether you are looking to manufacture the next generation of robotics, aerospace components, or medical implants, the expertise found in Bangalore’s industrial corridors—led by innovators like Zeometrix—is unmatched. Precision is no longer a luxury; it is the standard. And in Bangalore, that standard is being set every single day.

Frequently Asked Questions (FAQs)

1. What makes Zeometrix different from other CNC manufacturers in Bangalore?

Zeometrix stands out due to its "Design for Manufacturability" (DFM) focus. We don't just machine parts; we work with you to optimize your designs for cost, speed, and quality. Additionally, our investment in 5-axis technology and AI-driven quality control puts us at the forefront of the industry.

2. Can I source raw materials through the manufacturer in Bangalore?

Yes. Most leading manufacturers, including Zeometrix, have a vetted network of material suppliers. We can source everything from standard Aluminum 6061 to specialized aerospace alloys like Titanium and Inconel, providing full material test reports (MTRs) for traceability.

3. What are the typical tolerances that can be achieved?

Standard CNC machining in Bangalore typically achieves tolerances of ±0.01 mm to ±0.05 mm. However, for specialized requirements, Zeometrix can achieve even tighter tolerances (micrometer level) depending on the material and part geometry.

4. How does the "Smart Manufacturing" trend in 2026 benefit the customer?

Smart manufacturing uses data and AI to make production more predictable. For the customer, this means fewer defects, more consistent quality across batches, and more accurate delivery timelines due to predictive maintenance and real-time monitoring.

5. Does Zeometrix support "Make in India" initiatives for foreign companies?

Absolutely. We assist international firms in "localizing" their manufacturing. By moving production to our Bangalore facility, global companies can reduce lead times, avoid high import duties, and benefit from the high-quality engineering talent available in India.