10+ Years of Excellence: Zeometrix – The Experienced CNC Company in Bangalore

For over a decade, Zeometrix has proudly stood at the forefront of precision engineering and CNC machining in Bangalore. As a CNC prototype development company in Bangalore for startups and engineers, Zeometrix has carved a reputation for delivering unmatched quality, precision, and reliability to clients across multiple sectors. In a city known for innovation, technology, and industrial growth, our journey of 10+ years of excellence reflects our commitment to advanced technology, engineering expertise, and customer satisfaction.

From aerospace components to medical devices, from automotive parts to custom industrial solutions, Zeometrix has been a trusted partner for companies that demand superior performance and flawless machining. This blog explores what sets Zeometrix apart, why Bangalore is the ideal base for our operations, and how our decade-long experience has transformed us into a leading CNC company in the region.

Experience Matters: What Makes Zeometrix Stand Out

CNC machining is a craft that requires technological mastery, skilled operators, and deep material understanding. With more than ten years of specialized experience, Zeometrix brings:

1. Proven Technical Expertise

Our team has mastered:

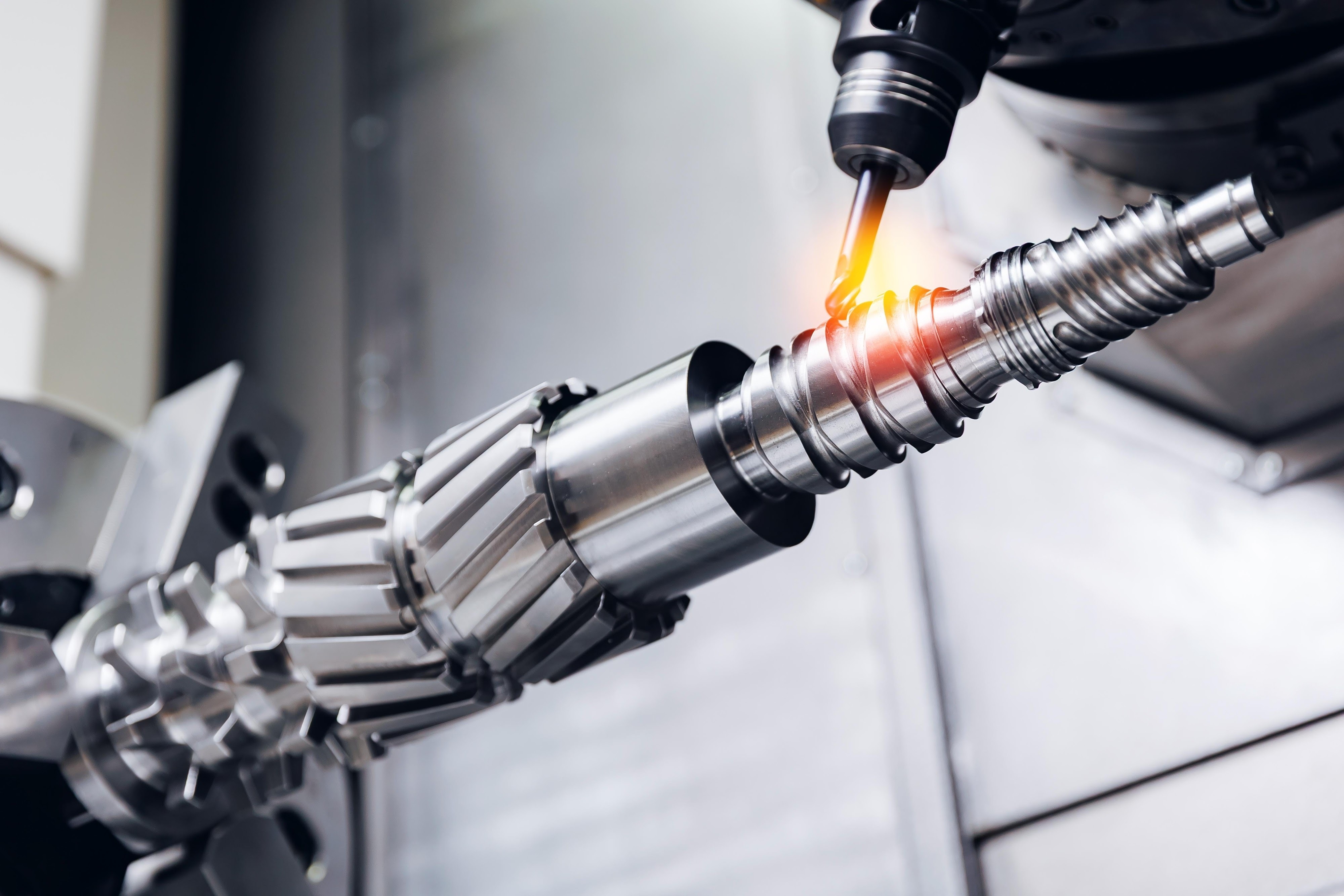

- Multi-axis machining

- High-precision component development

- Complex geometries

- Tight tolerances

- Material-specific machining

Whether it’s aluminium, stainless steel, titanium, engineering plastics, or exotic alloys, Zeometrix ensures accurate results every time.

2. Strong Quality Control System

Quality is embedded into our culture. Over the years, we have built:

- A strict quality management system

- In-house inspection and testing capabilities

- Industry-standard certifications

- End-to-end quality traceability

Our precision-driven approach ensures minimal errors and maximum reliability.

3. Capability to Handle Complex Projects

From prototypes to mass production, Zeometrix has the expertise to handle:

- Aerospace-grade components

- High-volume automotive parts

- Medical and surgical equipment components

- Defence and electronics precision parts

- Customized industrial requirements

Our diverse portfolio makes us a versatile CNC partner.

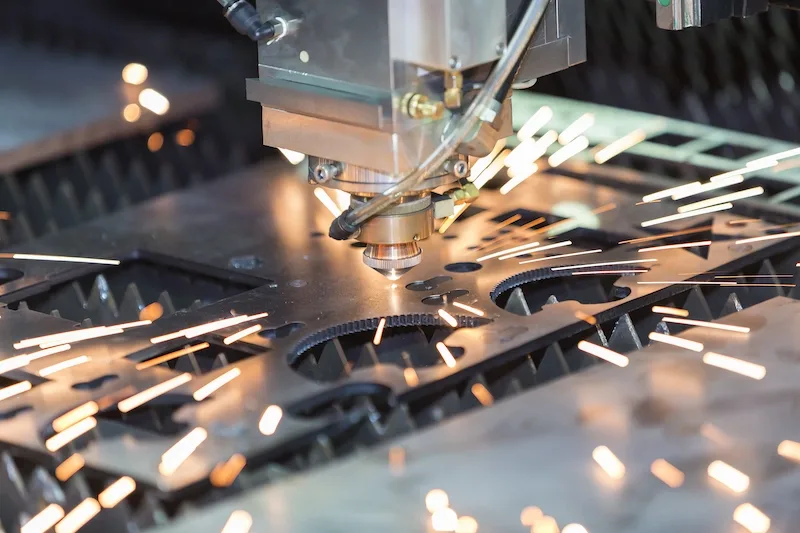

4. Technological Upgradation

The CNC industry evolves rapidly. Zeometrix consistently invests in:

- Advanced machining centers

- CAD/CAM integrated workflows

- High-speed, 5-axis CNC machines

- Toolpath optimization software

- IoT-enabled machine monitoring

This ensures we always stay ahead of industry standards.

Why Zeometrix Thrives in Bangalore’s Industrial Ecosystem

Bangalore is known worldwide as India’s technology powerhouse, but its manufacturing ecosystem is equally strong. Being based here helps Zeometrix leverage the best industrial environment for CNC machining.

1. Access to Key Industries

We work closely with multiple sectors in and around Bangalore, such as:

- Aerospace (HAL, ISRO ecosystem)

- Automotive and EV manufacturing

- Medical devices and biotech

- Defence equipment manufacturing

- Electronics and semiconductor industries

This exposure helps us develop world-class engineering solutions.

2. Skilled Engineering Talent

Bangalore produces some of India’s finest engineers, machinists, and CAD/CAM programmers. Zeometrix has built a team of highly skilled professionals who bring experience, innovation, and attention to detail to every project.

3. Advanced Technology Availability

With easy access to cutting-edge technology, Zeometrix stays at the forefront of CNC advancements, including:

- CNC simulation tools

- CMM and laser inspection

- Automated machining systems

- Smart manufacturing solutions

These technologies enhance accuracy, speed, and consistency.

4. Strong Supplier Network

Bangalore’s manufacturing ecosystem provides seamless access to raw materials, surface finishing, heat treatment, and tooling suppliers—allowing Zeometrix to deliver projects faster and more efficiently.

A Decade of Innovation, Precision & Customer Satisfaction

Zeometrix has spent over 10 years refining and perfecting our capabilities as a CNC machining company in Bangalore specializing in aluminum and stainless steel parts.

1. Industry-Specific Knowledge

We understand the needs of industries such as:

- Aerospace

- Automotive

- Electronics

- Medical

- Defence

- Industrial machinery

Each sector has unique requirements, and Zeometrix delivers components that meet exact specifications and standards.

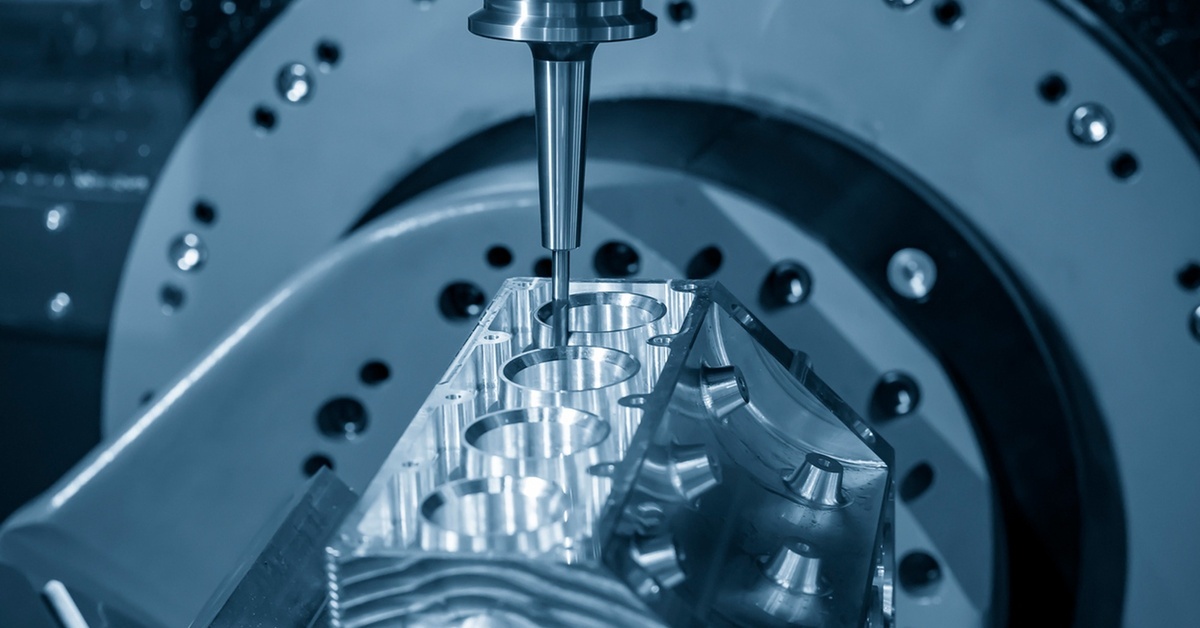

2. State-of-the-Art Machinery

Our equipment includes:

- 3-axis, 4-axis, and 5-axis CNC machining centers

- High-precision CNC turning machines

- Automated tool changers

- CAD/CAM programming and simulation systems

This machinery enables us to deliver consistent accuracy and high-volume performance.

3. Skilled and Dedicated Team

Our team consists of:

- Expert machinists

- CAD/CAM specialists

- Quality engineers

- Project managers

- Tooling and fixture designers

Their combined expertise ensures seamless end-to-end project execution.

4. Customer-Centric Philosophy

At Zeometrix, our focus has always been on:

- Clear communication

- On-time delivery

- Custom machining solutions

- Cost-effective production

- Long-term partnerships

We believe in creating value for our clients through precision and reliability.

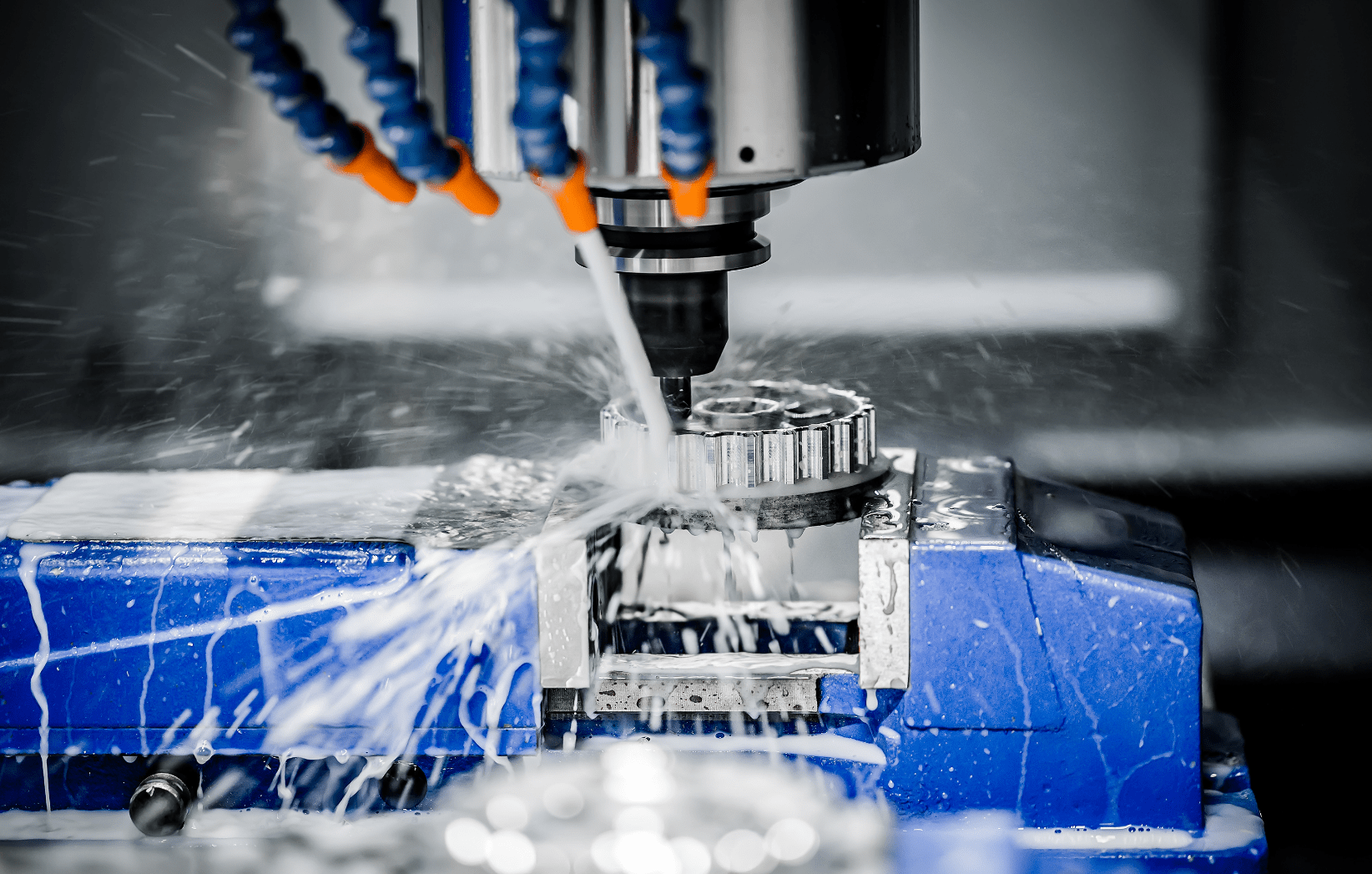

5. Strong Quality Assurance

Quality is at the heart of everything we do. Our processes include:

- First Article Inspection (FAI)

- Statistical Process Control (SPC)

- Coordinate Measuring Machine (CMM) inspection

- 100% traceability for critical components

This ensures every part meets or exceeds customer expectations.

Serving Multiple Industries with Precision

Zeometrix is a preferred CNC machining partner for diverse industries, including:

Aerospace & Defence

- Engine components

- Structural parts

- Sensor housings

- Prototypes and R&D components

Automotive & Electric Vehicles

- Engine and gearbox parts

- EV motor components

- Jigs and fixtures

Electronics & Semiconductors

- Heat sinks

- Custom enclosures

- Miniature precision parts

Medical & Healthcare

- Surgical instruments

- Implant components

- Diagnostic device parts

Industrial & Robotics

- Custom machine parts

- Precision tooling

- Robotic arm components

Innovation: The Driving Force at Zeometrix

To maintain our leadership in CNC machining, Zeometrix focuses on continuous innovation through:

1. Lean Manufacturing Practices

We optimize processes to reduce waste, improve efficiency, and lower costs.

2. Smart Machine Monitoring

IoT-based machine monitoring ensures:

- Reduced downtime

- Real-time data

- Better preventive maintenance

3. Rapid Prototyping & Production

We help clients move quickly from concept to prototype to full-scale production.

4. Automation & Robotics

Automation improves consistency, speed, and repeatability—especially for large orders.

5. Sustainable Manufacturing

Zeometrix prioritizes eco-friendly machining with reduced material waste and energy-efficient processes.

Why Choose Zeometrix for CNC Machining in Bangalore?

Partnering with Zeometrix means choosing:

- 10+ years of proven experience

- Advanced CNC technology

- Precision-driven manufacturing

- Flexible production capabilities

- Highly skilled engineering teams

- Faster turnaround times

- Uncompromising quality

We don’t just deliver components—we deliver confidence.

Conclusion: Zeometrix – A Trusted Leader in CNC Excellence

For more than a decade, Zeometrix has been committed to precision, quality, and customer satisfaction. Our journey of 10+ years reflects a passion for engineering excellence, continuous growth, and strong client relationships. As the manufacturing world becomes more demanding, Zeometrix remains dedicated to staying ahead with innovative technologies, skilled teams, and industry-ready solutions.

Whether you need complex aerospace components, high-volume automotive parts, or custom machining solutions, Zeometrix, a CNC machining service provider in Bangalore offering custom engineering solutions, is your reliable CNC partner—now and for the next decade of innovation.

FAQs

1. What makes Zeometrix different from other CNC companies in Bangalore?

Zeometrix stands out due to its 10+ years of experience, advanced machinery, strict quality standards, skilled team, and the ability to handle both simple and highly complex machining projects.

2. Does Zeometrix provide prototype development?

Yes. We specialize in rapid prototyping as well as full-scale production, helping clients move from design to finished product efficiently.

3. Which industries does Zeometrix cater to?

We serve aerospace, automotive, defence, medical, electronics, semiconductors, robotics, and various industrial sectors.

4. Can Zeometrix handle customized machining requirements?

Absolutely. We offer tailored CNC machining solutions based on customer designs, material requirements, and performance specifications.

5. How does Zeometrix ensure precision and quality?

We follow rigorous quality control practices including FAI, SPC, in-house CMM inspection, toolpath simulation, and experienced machinists who ensure every component meets exact specifications.