The CNC Hub: Choosing the Right Advanced Manufacturing Partner in Bangalore

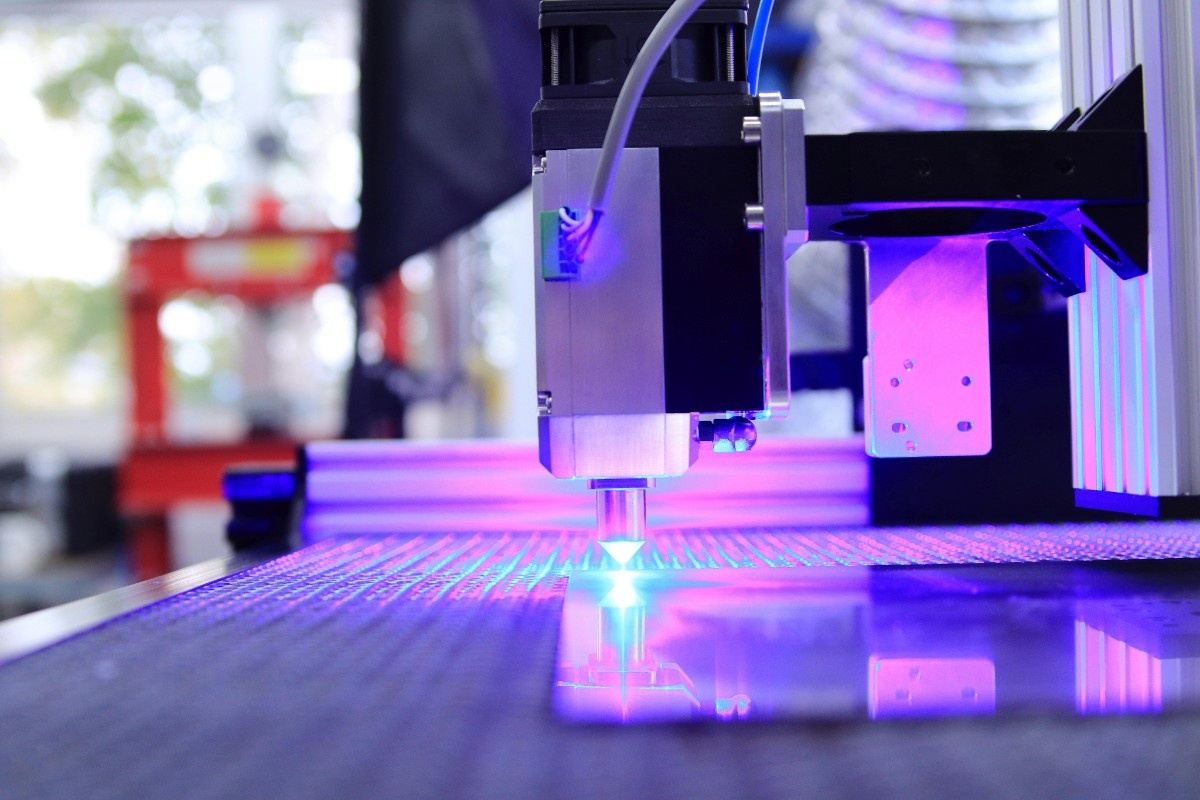

Bangalore, India’s "Silicon Valley," is also rapidly cementing its reputation as a global hub for precision engineering and manufacturing. At the core of this industrial revolution is CNC (Computer Numerical Control) machining, a process that demands absolute accuracy, micron-level tolerances, and unwavering consistency. Today, many companies specifically seek CNC milling and turning services in Bangalore for prototype manufacturing to accelerate product development and bring high-precision concepts to life. For businesses across aerospace, medical devices, automotive, and industrial automation, partnering with a reliable, technologically advanced CNC service provider is not just a choice—it’s a critical requirement for success.

Zeometrix stands at the forefront of this evolution, blending cutting-edge technology with deep-rooted engineering expertise right here in Bangalore. We don't just machine parts; we manufacture certainty, ensuring that every component meets the most demanding specifications and contributes directly to your product's performance and reliability.

The Zeometrix CNC Ecosystem: Capabilities That Deliver Unmatched Precision

The power of a CNC service provider lies in its machinery, its team, and its commitment to quality. At Zeometrix, we have cultivated an ecosystem built for precision, rapid turnaround, and scalability, backed by state-of-the-art infrastructure.

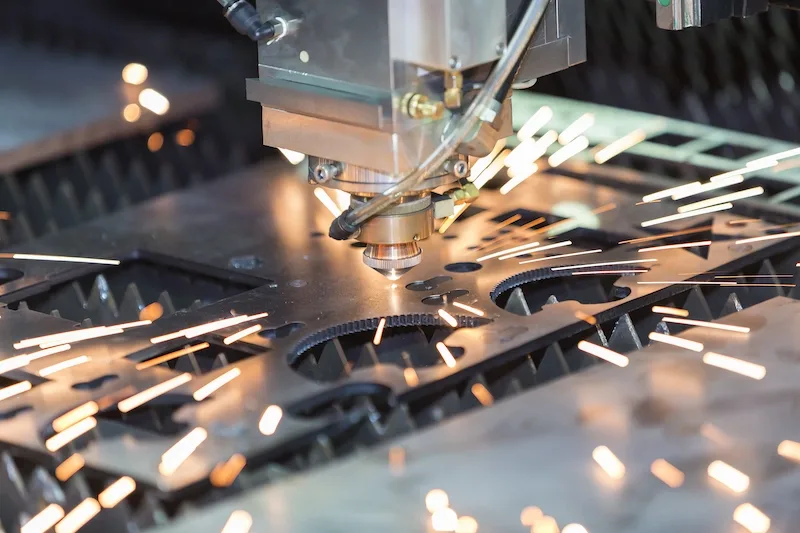

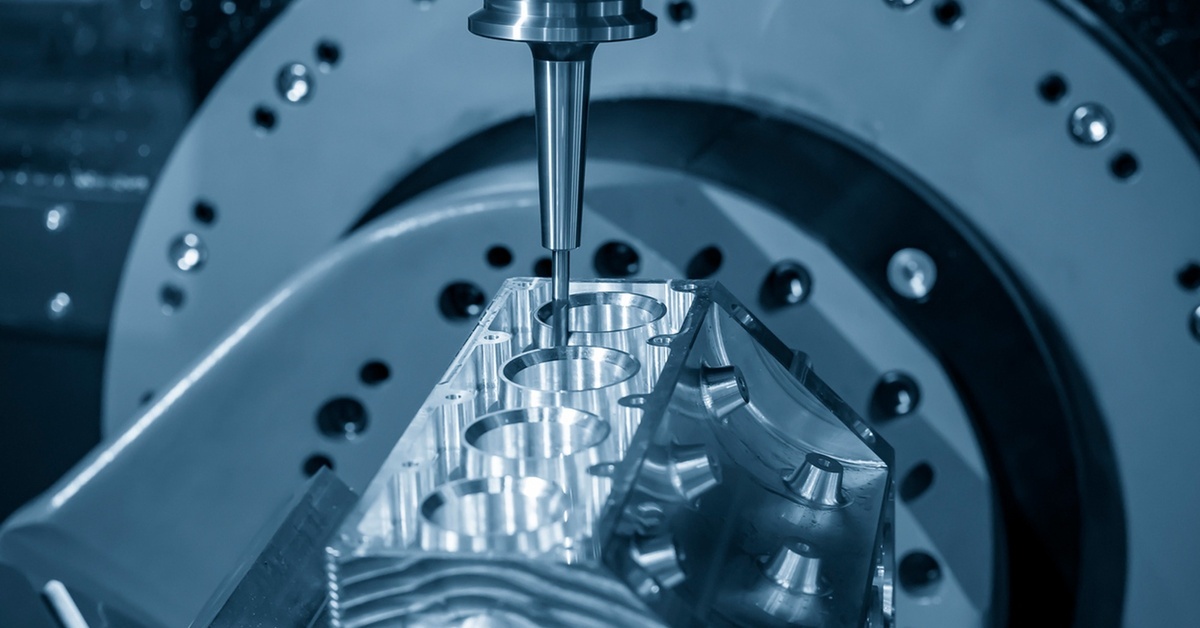

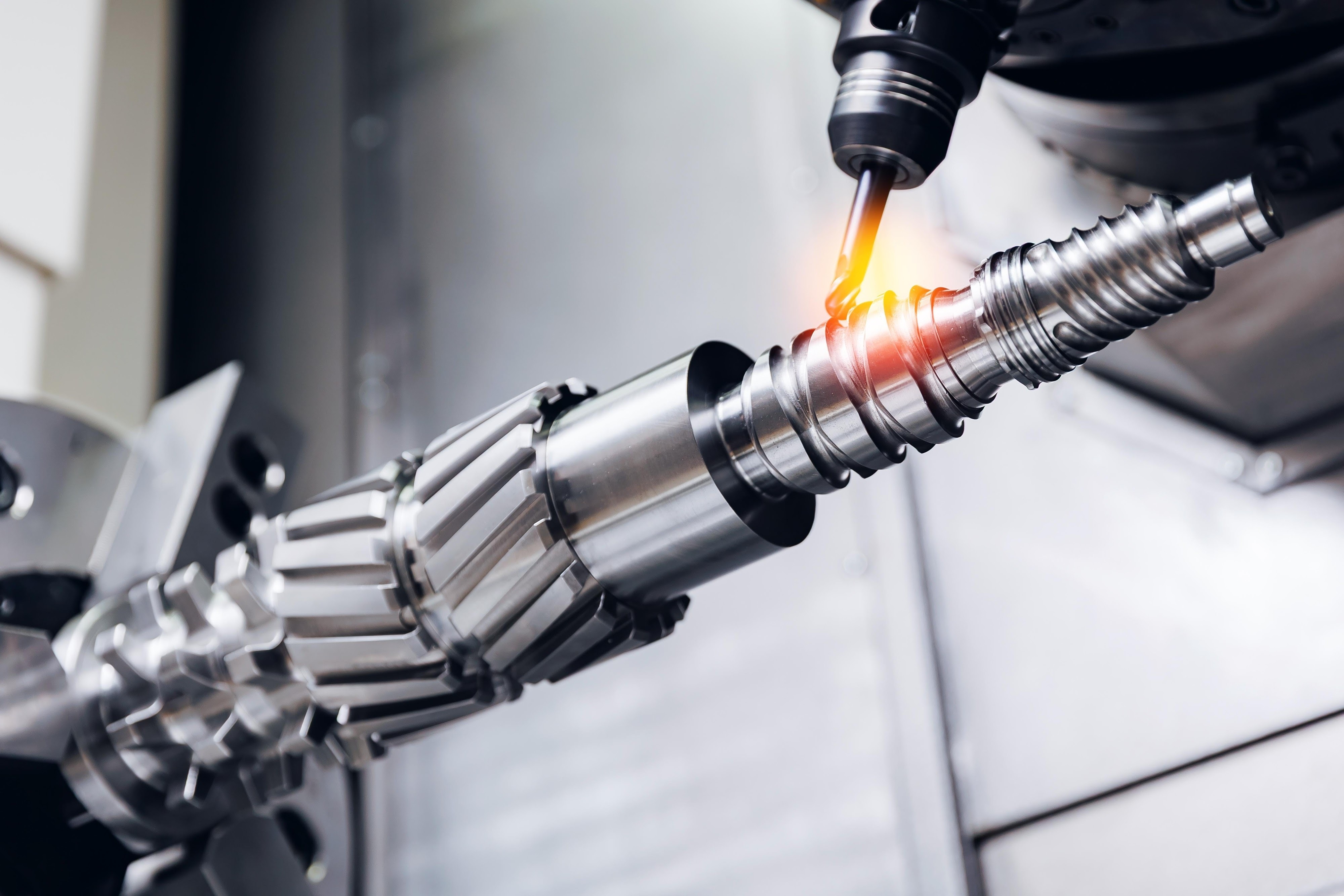

1. Advanced Multi-Axis Machining: Complexity Simplified

.jpg)

The complexity of modern components often surpasses the capabilities of standard 3-axis machines, which are limited in their ability to machine deep cavities or undercut features without multiple time-consuming setups. Zeometrix specializes in:

- 5-Axis CNC Machining: This is the cornerstone of our high-precision service. By allowing simultaneous movement along five axes (X, Y, Z, and two rotational axes, A and C), we can machine highly complex, organic shapes—like turbine blades, intricate medical implants, or sophisticated mold cavities—in a single setup. This capability dramatically improves dimensional accuracy by eliminating repositioning errors, reduces setup time, and ensures an exceptional surface finish even on contoured surfaces. Our investment in premium 5-axis platforms from leading global manufacturers ensures machine rigidity and thermal stability, crucial for maintaining tight tolerances over long operational runs.

- 4-Axis Milling & Turning: Ideal for cylindrical parts that require off-center features, drilling, or milling along the circumference, our 4-axis capabilities provide the perfect balance of speed and precision for high-volume, multi-featured components, such as valve bodies and specialized shafts.

- Turn-Mill Technology: Integrating milling and turning onto a single platform, our turn-mill centers eliminate the need to move a part between different machines. This reduces handling errors and achieves greater geometric accuracy between turned and milled features, essential for components like complex hydraulic manifolds.

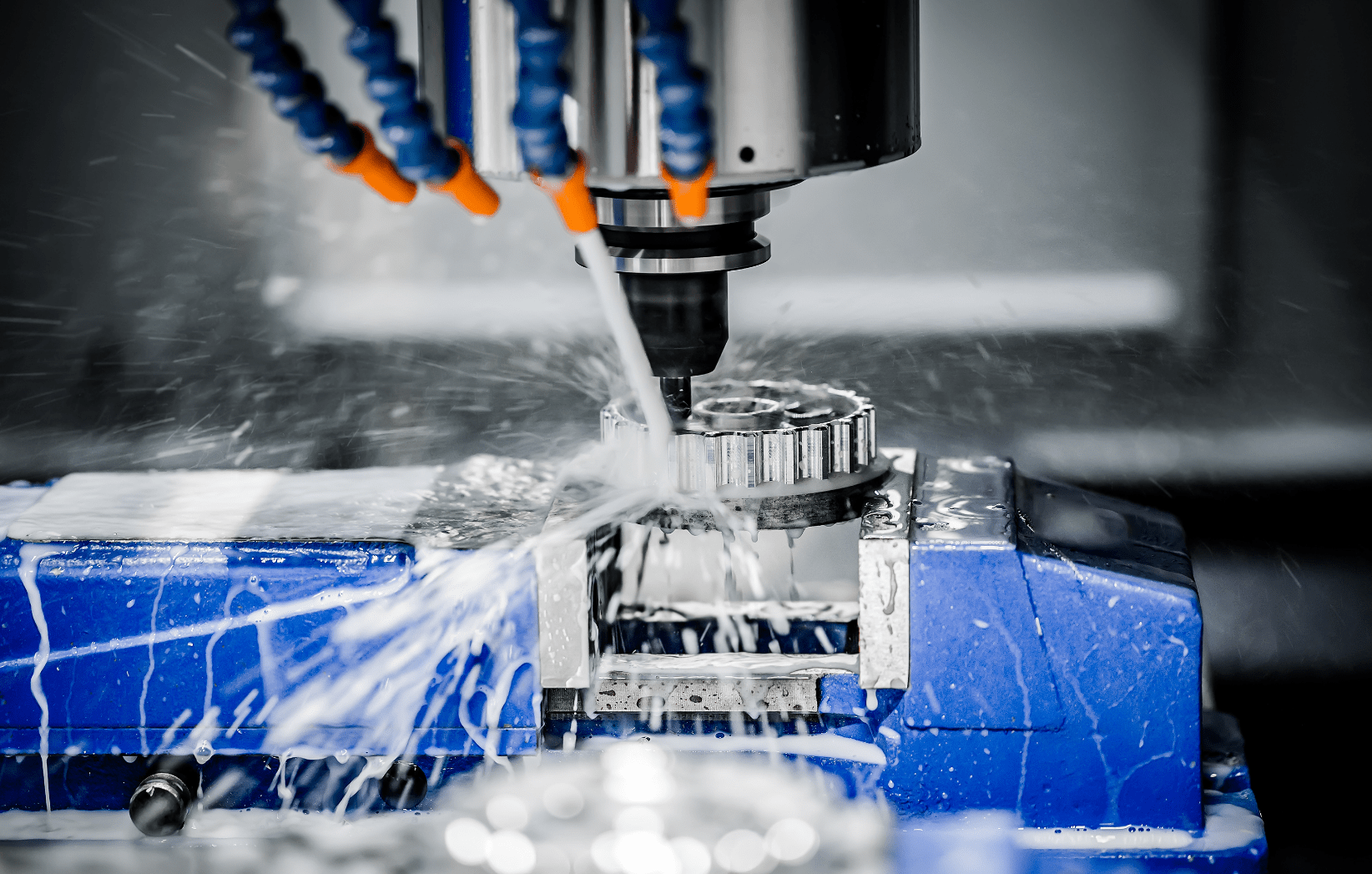

2. Full Material Spectrum Expertise: Mastering the Challenging Alloys

Our experience spans the entire range of engineering materials, ensuring we can deliver parts that not only fit but also perform under the required operational stresses. Machining high-performance materials requires specialized tooling, optimized cutting strategies, and strict control over thermal dissipation.

|

Material Category |

Examples & Applications |

Zeometrix Machining Advantage |

|

Aerospace/High-Strength |

Titanium (Ti-6Al-4V), Inconel (718, 625), High-Nickel Alloys |

Specialized use of High-Pressure Coolant (HPC) and Carbide tooling to manage material work-hardening, low thermal conductivity, and tool wear, ensuring structural integrity for critical aerospace parts. |

|

High-Precision Metals |

Aluminum (6061, 7075), Stainless Steel (304, 316), Tool Steel |

Optimized high-speed machining (HSM) techniques for high-volume, fine-feature work, achieving superior surface finishes and maintaining flatness across large parts. |

|

Engineering Plastics |

PEEK, Delrin (Acetal), Nylon, Polycarbonate, PTFE |

Use of vapor-phase or non-contact clamping, minimized cutting forces, and optimized cooling cycles to prevent material warping, heat deformation, and stress induction, ensuring precise dimensions on sensitive polymer parts. |

3. Integrated Secondary Operations and Finishing

A part is not complete until it meets the final functional and cosmetic requirements. Zeometrix operates a dedicated post-processing facility, ensuring that the critical final steps are managed under the same rigorous quality control system.

- Precision Grinding: For components requiring exceptionally tight geometric tolerances ($< 5\ \mu\text{m}$) and super-fine surface finishes ($< \text{Ra}\ 0.2\ \mu\text{m}$), we employ CNC Surface Grinding and Cylindrical Grinding. This is crucial for sealing faces, bearing bores, and mating surfaces.

- Surface Finishing & Treatment: We manage and certify processes including Anodizing (Type II and Type III Hard Coat for corrosion/wear resistance), Chemical Film (Chromate Conversion), Passivation (for stainless steel corrosion protection), and specialized coatings like Black Oxide or Electroless Nickel Plating.

- Heat Treatment & Metallurgical Analysis: We coordinate and verify all required heat treatments (e.g., solution treating, age hardening, normalizing) with certified partners, providing full material certification (MTC) and testing results to guarantee desired mechanical properties (hardness, tensile strength).

Unmatched Quality Assurance: The Zeometrix Quality Matrix (ZQM)

In precision manufacturing, quality is not an afterthought—it's the core of the process. At Zeometrix, known for delivering CNC machining and fabrication services in Bangalore for aluminum parts, our quality system goes beyond standard ISO compliance. The Zeometrix Quality Matrix (ZQM) is a multi-layered protocol integrated into every stage of the manufacturing workflow.

The ZQM Inspection Protocol

- Pre-Machining Verification: Before the first cut, material certifications (MTCs) are validated, and tools/fixtures are calibrated. The CAM program is run through a software simulation to detect potential collisions or programming errors, ensuring first-time-right manufacturing.

- In-Process Monitoring (IPC): Operators use calibrated digital bore gauges, micrometers, and surface roughness testers to perform checks at set intervals. Our machines are equipped with in-situ probing systems that automatically measure key features and compensate for tool wear or thermal drift, ensuring real-time geometric consistency.

- Final Dimensional Inspection (FDI): Every critical part moves to our climate-controlled Quality Lab for final inspection.

- Coordinate Measuring Machine (CMM) Inspection: We utilize advanced CMMs with non-contact scanning and tactile probing capabilities. The CMM is programmed directly from the original CAD model, ensuring an objective, automated inspection of every specified dimension and geometric tolerance (GD&T).

- Traceability: Full inspection data, including First Article Inspection (FAI) reports and CMM data logs, are generated and archived, providing complete traceability from raw material to the finished part, a requirement for aerospace and medical clients.

The Strategic Advantage of Partnering with Zeometrix in Bangalore

Choosing Zeometrix for your CNC machining needs in Bangalore provides a strategic edge over outsourcing globally or relying on less specialized local firms.

1. Cost-Effective Engineering Expertise

Our location in Bangalore gives us access to a large pool of highly trained, English-speaking mechanical and manufacturing engineers. This allows for direct, clear technical communication and the provision of high-value Design for Manufacturability (DFM) consultation at globally competitive labor rates. We ensure that your design is optimized to be machined efficiently, often reducing cycle times and material waste, leading to overall lower unit costs.

2. Fast, Scalable, and De-Risked Supply Chain

Working with a local, certified partner simplifies logistics and reduces exposure to global supply chain disruptions. We offer:

- Agile Prototyping: Dedicated machine cells for rapid prototype runs, delivering parts in as little as 3-5 days.

- Seamless Scaling: Our infrastructure is designed for modular growth, allowing us to quickly transition from a low-volume prototype run to sustained high-volume production without sacrificing quality or lead time consistency.

- JIT (Just-in-Time) Delivery: We support local manufacturers with JIT supply chain integration, minimizing their inventory costs and reducing warehouse overhead.

3. Case Study: Achieving Zero Defect Rate for a Robotic Actuator Housing

A client, a multinational leader in industrial automation, required a complex aluminum housing for a new generation robotic actuator. The part required:

- Tight bearing bore tolerances ($\pm 0.005\ \text{mm}$).

- Multiple intersecting internal channels and features requiring 5-axis access.

- A cosmetic Type III Hard Anodize finish.

The Challenge: Initial attempts with other vendors failed due to geometric errors arising from multiple setups and surface finish inconsistencies in the internal channels.

The Zeometrix Solution:

- DFM Optimization: We recommended a slight adjustment to the corner radii to improve tool access and reduce machining stress.

- Single-Setup 5-Axis Strategy: The part was machined entirely on a 5-axis center in a single clamping setup, eliminating stacking errors from re-positioning.

- In-Situ Probing: Key bore diameters were probed automatically mid-cycle to apply tool compensation, maintaining the critical $\pm 0.005\ \text{mm}$ tolerance throughout the batch.

- ZQM Verification: Every single finished unit underwent CMM inspection, cross-referencing over 50 data points against the CAD model.

The Result: Zeometrix delivered the entire 500-unit batch on time with a zero defect rate (0 ppm), exceeding the client's quality expectation and leading to a significant acceleration of their product launch schedule.

Conclusion: Your Partner in Precision Manufacturing

The future of engineering demands precision, speed, and uncompromising quality. The complexity of modern parts in industries like robotics, defense, and high-end automotive requires a manufacturing partner who can deliver more than just a cut part—it requires a partner who can deliver Zeometrix precision.

By choosing Zeometrix for your CNC machining services in Bangalore, you are partnering with one of the trusted CNC machining manufacturers in Bangalore for precision engineering solutions, ensuring a commitment to advanced technology, industry-leading quality control, and a team dedicated to turning your most ambitious designs into flawless physical realities. We are not just a service provider; we are the precision engineering backbone of your product's success.

Ready to transform your design into a high-precision component? Upload your CAD file today and experience the Zeometrix difference.

Frequently Asked Questions (FAQ)

Q1: What makes Zeometrix's CNC services in Bangalore unique compared to other providers?

A1: Zeometrix distinguishes itself through its specialization in 5-Axis Machining for complex geometries and difficult-to-machine materials like Titanium and Inconel. We implement a stringent internal quality control protocol, the Zeometrix Quality Matrix (ZQM), which mandates CMM inspection for all critical dimensions. Furthermore, our focus on Design for Manufacturability (DFM) consultancy ensures that we partner with you to optimize your design for both performance and cost-efficiency right from the start.

Q2: Which quality certifications and standards does Zeometrix meet?

A2: Zeometrix is compliant with the internationally recognized ISO 9001:2015 Quality Management System. Our operational procedures and documentation meet the traceability and process control requirements demanded by the aerospace (AS9100 principles) and medical device (ISO 13485 principles) sectors, ensuring we can provide full material traceability (MTCs), dimensional reports, and FAI documentation for highly regulated components.

Q3: What is the typical turnaround time for a CNC machining project at Zeometrix?

A3: Our lead times are optimized for speed and quality.

- Rapid Prototypes (Low Complexity): Typically ranges from 3 to 7 working days after receiving the order and finalising the design review.

- Complex or High-Volume Runs: Final timelines are quoted based on material availability and machine hours, but our lean manufacturing principles and multi-axis capabilities ensure we provide some of the fastest, most reliable deliveries in the Bangalore market. We utilize advanced CAM software to drastically reduce programming and setup time.

Q4: Does Zeometrix offer assistance with part design, material selection, and finishing requirements?

A4: Yes, absolutely. Our Design for Manufacturability (DFM) service is integral to our partnership approach. Our mechanical engineers will review your 3D models and specifications (GD&T) to suggest optimal material grades, appropriate finishing processes (e.g., specific type of Anodizing or heat treatment), and design adjustments that can simplify the machining process, reduce costs, and improve the part's final functional performance.

Q5: Can Zeometrix handle both small-batch prototyping and large-scale production orders?

A5: Yes. Zeometrix is structured for scalability. We have dedicated machine cells for quick-turn prototype work, allowing us to validate your design efficiently. Once the prototype is approved, we seamlessly transfer the process parameters, tooling, and fixturing to our larger production floor, enabling us to handle consistent, high-volume batch production runs (into the tens of thousands) while maintaining the zero-defect quality achieved during the initial prototyping phase.