Sheet Metal Fabrication in Bangalore – Custom & Industrial Solutions

At Zeometrix, we specialize in precision-engineered sheet metal parts, structures, and assemblies that deliver exceptional strength, accuracy, and durability. As a trusted provider of Sheet Metal Fabrication in Bangalore , we offer complete end-to-end services — from prototyping to full-scale production. Our skilled team uses advanced tools and manufacturing techniques to meet the highest industry standards, ensuring every component we produce reflects superior craftsmanship, reliability, and performance across various industries.

Trusted by more than 10,000 engineers and procurement leaders

Sheet Metal Services Available at Zeometrix

Sheet Metal Fabrication in brief

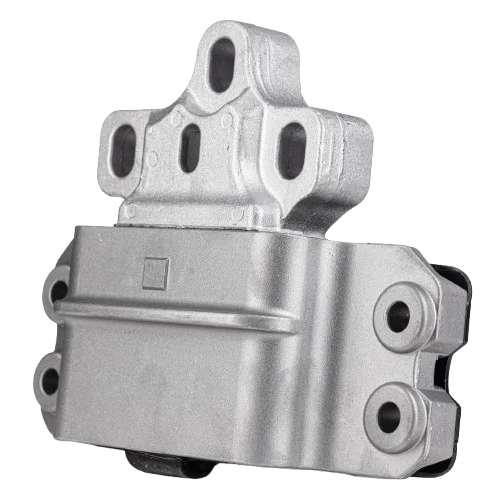

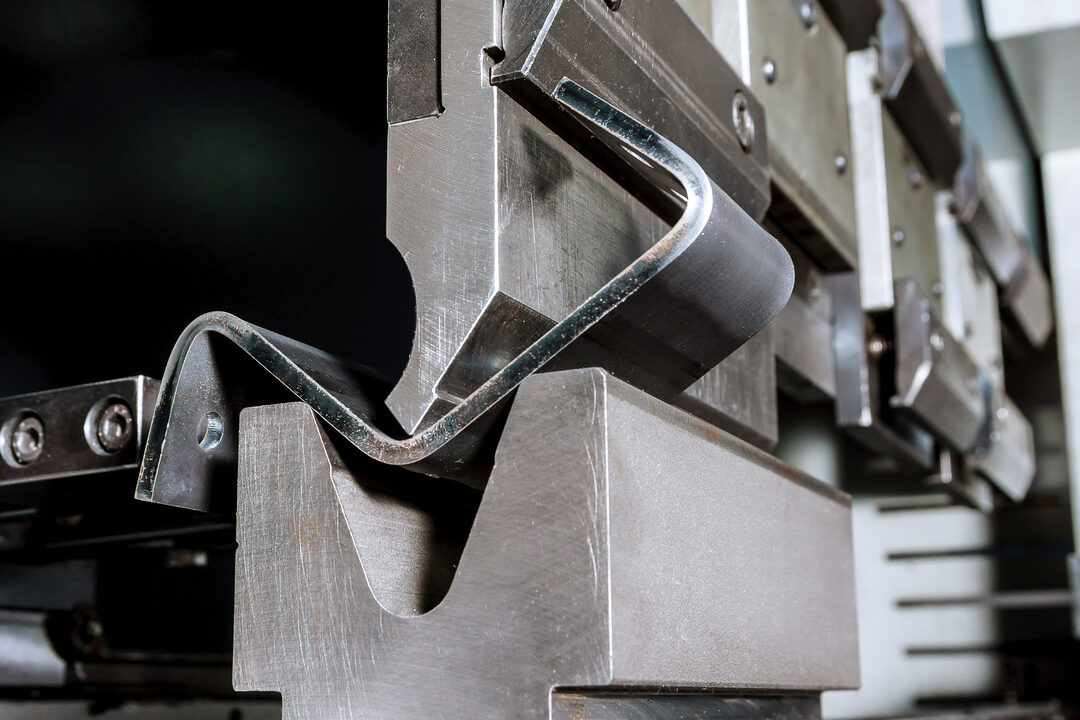

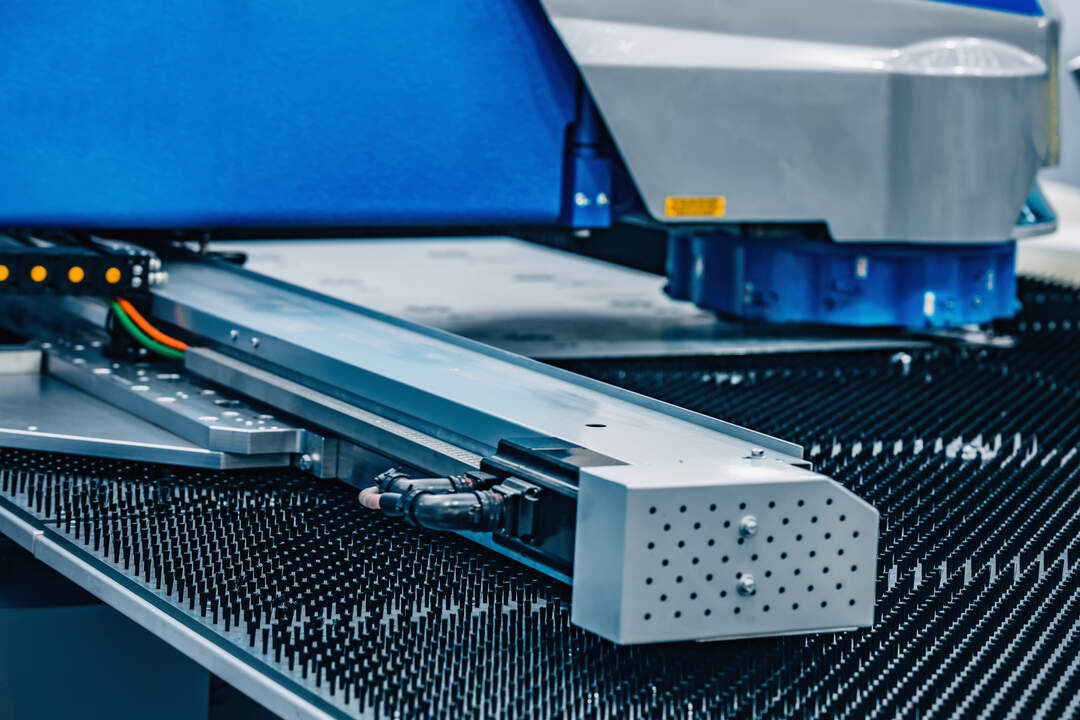

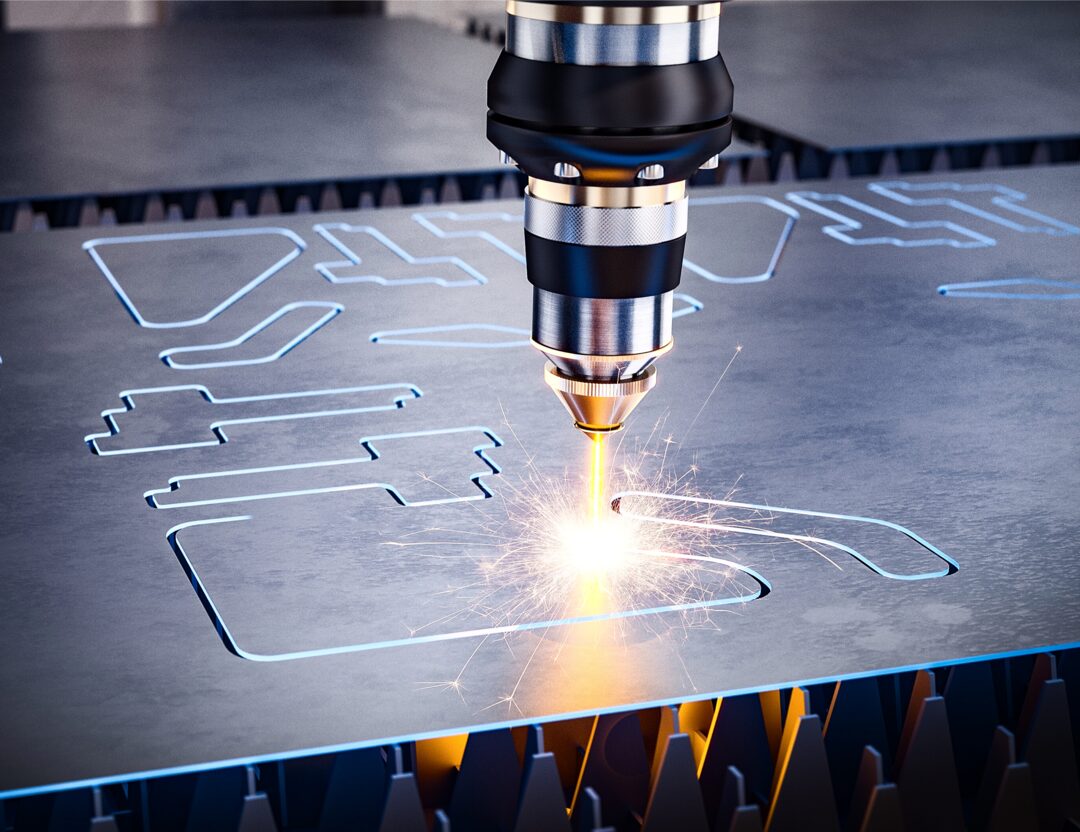

At Zeometrix, we manufacture a wide range of sheet metal fabrication and metal fabrication works for automobile parts, machinery parts, metal components, structures, racks, panels, and machine assemblies. For Sheet Metal Fabrication, most of our clients rely on us to handle end-to-end manufacturing, from production to final assembly. At our End-To-End assembly manufacturing unit, we procure standard child parts, manufacture machined components through VMC and CNC machining, produce sheet metal parts through Laser Cutting – CNC Bending – TIG/MIG/CO2 Welding – Powder Coating, and finally assemble them, all while maintaining tight tolerances. We are known for precision manufacturing and have delivered several aesthetically demanding products such as AMR Bots, EV Dumpers, EV Tractor Parts, EV Battery Assemblies, Electric Scooter Parts, Charging Stations, Standing Kiosks, and many more. With our own facility dedicated to Sheet Metal Fabrication and a large pool of partner vendors, we work on high-volume production for leading OEMs. We also love collaborating with startups, supporting them from grassroots innovation to scaled production over time.

Zeometrix Sheet Metal Fabrication Capabilities

| Features | Descriptions |

|---|---|

| Material | Mild Steel, Stainless Steel, Aluminum, Copper and other materials |

| Laser Cutting | upto 6 KW |

| Bending | upto 200 Ton |

| Punching Thickness | Up to 8mm |

| Welding | TIG / MIG / CO2 |

| Powder Coating | 3 Tank / 7 Tank Process |

Zeometrix Sheet Metal Fabrication Process

We make sheet metal fabrication seamless. Start by uploading your CAD file in the user section, get an instant quote, and review any specific instructions. Once the quote is approved, production begins either in-house or via our network of top-quality sheet metal fabricators in India and worldwide. You’ll receive updates on progress and estimated lead times. Upon completion, parts are delivered on time with detailed reports and secure packaging. Submit your requirements through the user portal or reach out via chat for immediate support at support [at] zeometrix.com.

Sheet Metal Fabrication

-

What is sheet metal fabrication?

Sheet metal fabrication is an important procedure in the manufacturing industry, involving the transformation of flat sheets of metal into various shapes, sizes and structures. considering its adaptability and efficiency, this method is extensively applied in many different fields, including automotive, aerospace, building, and electronics.

Important Sheet Metal Fabrication Processes : Laser Cutting, CNC Bending, Welding, Punching and powder coating.

-

What are different types of metal sheet available ?

There are different types of sheet metal available, each offers unique properties and applications. Here’s an overview of the most common types:

Alloy Steel: An affordable option with Strength and Rigidity.

Stainless Steel: Known for its corrosion resistance, prevents rusting and available in different grades.

Carbon Steel: Made by alloying iron with carbon, this metal is available in low, medium, and high carbon content. Depends on strength and application, material grade is evaluated.

Galvanized Steel: This steel is coated with zinc to prevent rusting. It is commonly used in outdoor applications where exposure to the elements is a concern.

Aluminum: Lightweight and corrosion-resistant, usually preferred by automotive and aerospace industry ,come common grades, 1100, 3003, 5052, and 6061

Copper/Brass: great electrical conductivity and corrosion resistance, copper and brass are often used in electrical components and decorative items.

-

What is basically fabrication techniques?

Fabrications refers to creating components to make product or structures for manufacturing heavy machinery bodyparts .

-

What does CR sheet stands for?

CR is called cold rolled steel sheets which is known for its outstanding properties like smooth and clear surfaces which is used in everyday appliances.

-

What kind of tools are used for sheet metal fabrication?

Sheet metal fabrication uses a variety of tools to cut, bend, and shape metal into useful parts. Common cutting tools include shears (like big scissors for metal), snips, saws, and high-tech machines like laser or plasma cutters for precise shapes. To bend and form the metal, fabricators use press brakes, rollers, and hand seamers. For joining pieces together, welding tools are essential, while grinders and sanders help smooth and finish the metal. Simple measuring tools like rulers and scribes ensure accuracy. Together, these tools make it possible to turn flat metal sheets into strong, custom-made products.

Examples of Our Sheet Metal Fabrication Work

Bending and Forming: Shaping Metal to Fit Any Project

Orjo Bora

2024-11-07

Welding and Assembly: Strong, Durable Metal Connections

Orjo Bora

2024-11-07

CNC Punching: High-Speed Precision for Perforated Metal

Orjo Bora

2024-11-07

Cost-Effective Sheet Metal Fabrication Solutions in Bangalore

Orjo Bora

2025-06-13

How Precision Impacts Quality in Sheet Metal Manufacturing

Orjo Bora

2025-02-01

How Sheet Metal Fabricators in Bangalore Support the Aerospace Industry

Zeometrix

2025-06-28

The Role of CAD Software in Custom Sheet Metal Fabrication: A Comprehensive Guide

Orjo Bora

2025-07-04

How CAD Software Is Revolutionizing Custom Sheet Metal Design and Fabrication

Orjo Bora

2025-10-07

What to Expect from Professional Sheet Metal Fabrication Manufacturers

Orjo Bora

2025-07-19

How Sheet Metal Fabrication Manufacturers Are Supporting Custom Industrial Needs

Orjo Bora

2025-07-25

Laser Cutting to Assembly: End-to-End Sheet Metal Fabrication Explained

Orjo Bora

2025-08-02

The Zeometrix Advantage: ISO-Certified Sheet Metal Fabrication in India

Orjo Bora

2025-08-08

Global Sheet Metal Manufacturing | Engineering Excellence Delivered

Orjo Bora

2025-08-16

Large-Scale Sheet Metal Manufacturing in Bangalore: Why OEMs Prefer Zeometrix

Orjo Bora

2025-08-22

Comparing the Top Sheet Metal Fabricators in Bangalore: 2025 Guide

Orjo Bora

2025-08-30

End-to-End Sheet Metal Manufacturing: From CAD Upload to Final Assembly

Orjo Bora

2025-09-05

Latest Technologies Used by Sheet Metal Fabricators in Bangalore

Orjo Bora

2025-09-13

How Zeometrix Supports Make-in-India as Sheet Metal Fabricators in Bangalore

Orjo Bora

2025-09-19

Precision and Perfection: The Art of Sheet Metal Fabrication in Bangalore

Orjo Bora

2025-09-22

Affordable Sheet Metal Fabricators in Bangalore for Custom Projects

Zeometrix

2025-10-01

How Sheet Metal Fabrication Manufacturers Are Shaping Modern Industry

Zeometrix

2025-10-03

Affordable & Reliable Sheet Metal Fabrication in Bangalore

Zeometrix

2025-10-08

How Sheet Metal Fabrication Manufacturers Are Shaping Modern Industry

Zeometrix

2025-10-10

Leading Sheet Metal Fabrication Services in Bangalore

Zeometrix

2025-10-15

Sheet Metal Fabrication in Bangalore: The Hub of Precision Manufacturing

Zeometrix

2025-10-16

Get the Best Sheet Metal Fabrication in Bangalore Today

Zeometrix

2025-10-17

Why Bangalore Is Emerging as a Hub for Sheet Metal Fabrication

Zeometrix

2025-10-22

High-Quality Sheet Metal Fabrication in Bangalore for All Industries

zeometrix

2025-10-24

Forging the Future: How Sheet Metal Fabrication Fuels Bangalore’s Industrial Growth

zeometrix

2025-10-25

Sheet Metal Fabrication in Bangalore: An In-Depth Overview

zeometrix

2025-02-07

Sustainable and Smart: The Next Generation of Sheet Metal Fabrication at Zeometrix

Zeometrix

2025-11-07

Engineering Excellence from Top Sheet Metal Fabricators in Bangalore – Zeometrix

Zeometrix

2025-11-19

End-to-End Sheet Metal Fabrication Companies in Bangalore Under One Roof – Zeometrix

Zeometrix

2025-11-20

The Premier Sheet Metal Fabrication Firm, Bangalore | 10+ Years Experience

Zeometrix

2025-11-25

Advanced Sheet Metal Solutions Driving Innovation Across Bangalore’s Industries

Zeometrix

2025-12-23

Inside Bangalore’s Sheet Metal Industry: Technology, Talent, and Quality

Zeometrix

2025-12-30

The Rise of Advanced Sheet Metal Fabrication Companies in Bangalore

Zeometrix

2026-01-03

How Zeometrix Delivers High-Quality Sheet Metal Fabrication in Bangalore

Zeometrix

2026-01-06

From Blueprint to Brilliance: Choosing the Right Sheet Metal Fabricator in Bangalore

Zeometrix

2026-01-12

Building the Future: The Heavy Fabrication Powerhouses of Bangalore

Zeometrix

2026-01-31