Crafting the Future: The Intersection of Software, Hardware, and CNC Machining in Bangalore

Bangalore, often celebrated as the "Silicon Valley of India," has long been the heartbeat of the nation’s technological revolution. For decades, the narrative surrounding this city was dominated by software, coding, and the digital cloud. However, as we move through 2025, a parallel story is unfolding on the factory floors of the city’s sprawling industrial estates. Beyond the glass facades of IT parks lies a robust, high-precision manufacturing ecosystem that is arguably just as vital to the global economy as the software it powers.

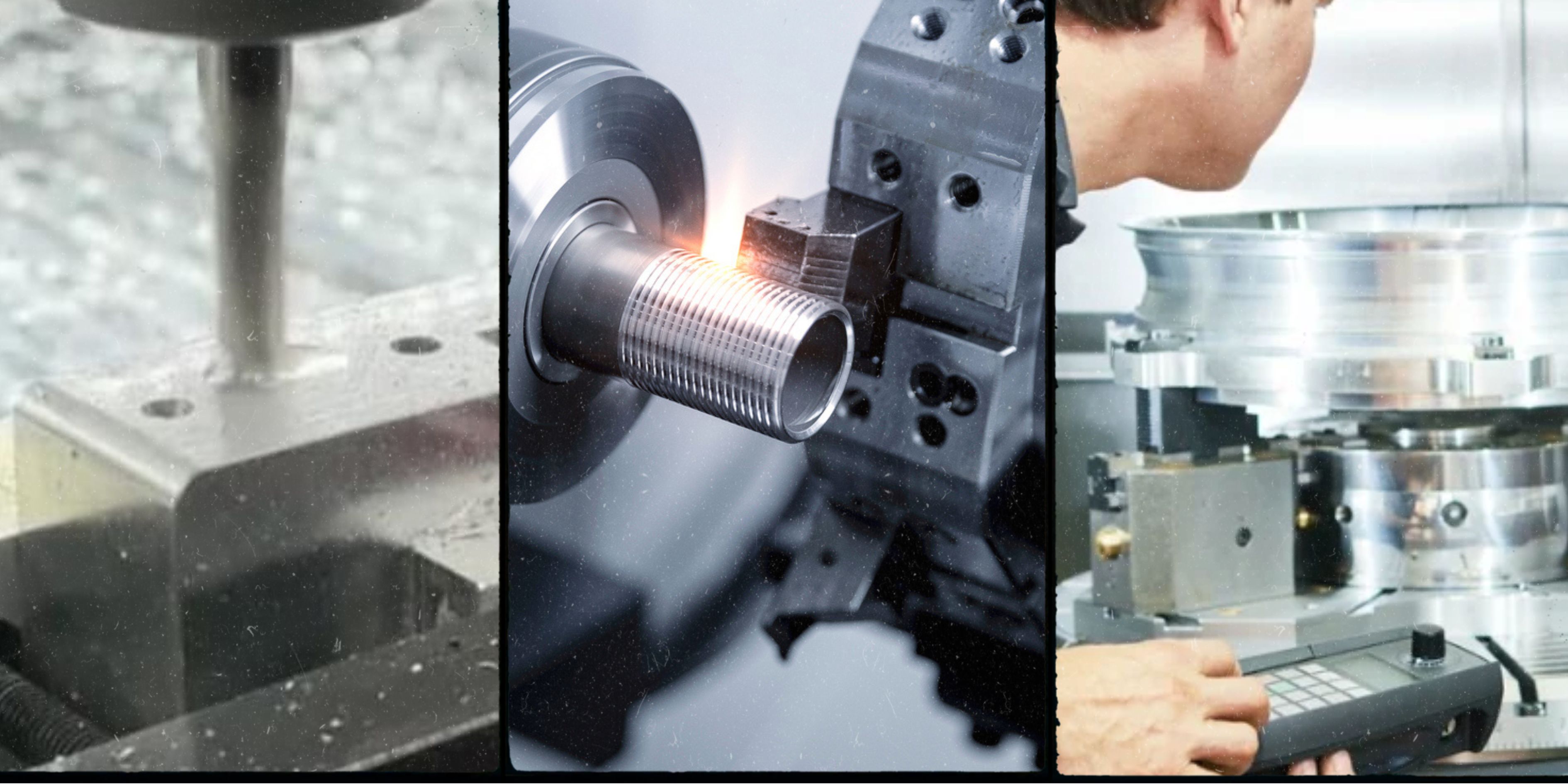

The demand for high-quality, reliable CNC machining services in Bangalore has reached an all-time high. This surge isn’t just about making "parts"—it’s about the convergence of hardware and software, where the digital designs of engineers are translated into physical reality with micron-level accuracy.

At the center of this industrial evolution is Zeometrix, a premier rapid manufacturing partner dedicated to bridging the gap between complex engineering designs and high-performance physical components. Whether you are an aerospace startup in Hebbal or a medical device manufacturer in Electronic City, understanding the nuances of modern CNC machining is critical to your product’s success.

1. The Bangalore Advantage: Why Local Precision Matters

Bangalore is not just a location; it is a manufacturing powerhouse with a heritage that dates back to the establishment of public sector giants like HAL (Hindustan Aeronautics Limited) and ISRO (Indian Space Research Organisation). This foundation created a "precision culture" that has now trickled down into a burgeoning ecosystem of EV (Electric Vehicle), robotics, and deep-tech startups.

When you seek CNC machining services in Bangalore, you aren't just buying machine time; you are tapping into a specialized ecosystem:

-

Proximity to Innovation: In the world of rapid prototyping, distance is the enemy of speed. Being close to your manufacturer means fast feedback loops. You can iterate on prototypes within days, physically inspecting a part in the morning and seeing a revised version by the following afternoon.

-

A Skilled Talent Pool: Bangalore boasts a unique density of specialized CNC programmers and machine operators. These are professionals who don't just follow instructions; they understand global standards like AS9100 and ISO 13485, ensuring that a part made in Bangalore is indistinguishable from one made in Munich or San Jose.

-

Logistical Efficiency: By localizing your supply chain with a partner like Zeometrix, you eliminate the headaches of international shipping, fluctuating exchange rates, and customs delays.

Zeometrix is strategically located to serve the Bommasandra, Jigani, and Peenya industrial belts, leveraging this local expertise to provide businesses with global-standard precision right at their doorstep.

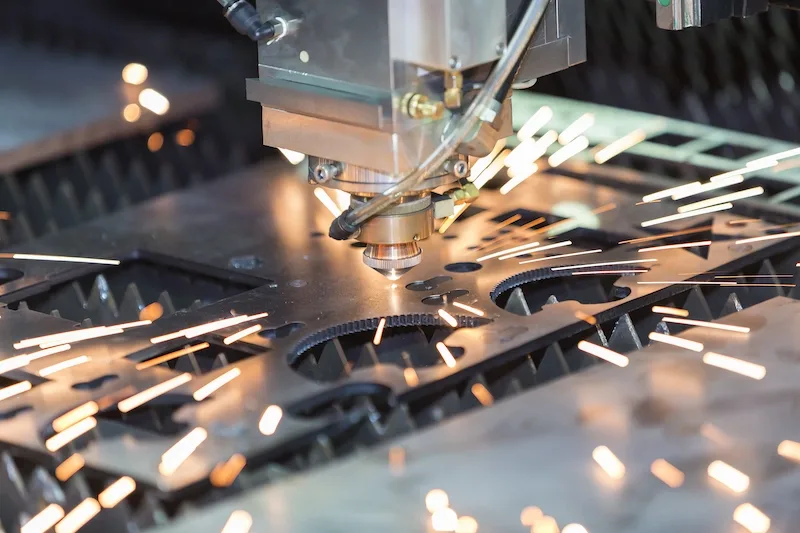

2. Deciphering CNC Machining: The Zeometrix Core

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where raw material is removed with a variety of precision cutting tools to create a final part. At Zeometrix, we view this as more than just "cutting metal"; we see it as a high-stakes translation of engineering intent.

CNC Milling (3, 4, and 5-Axis)

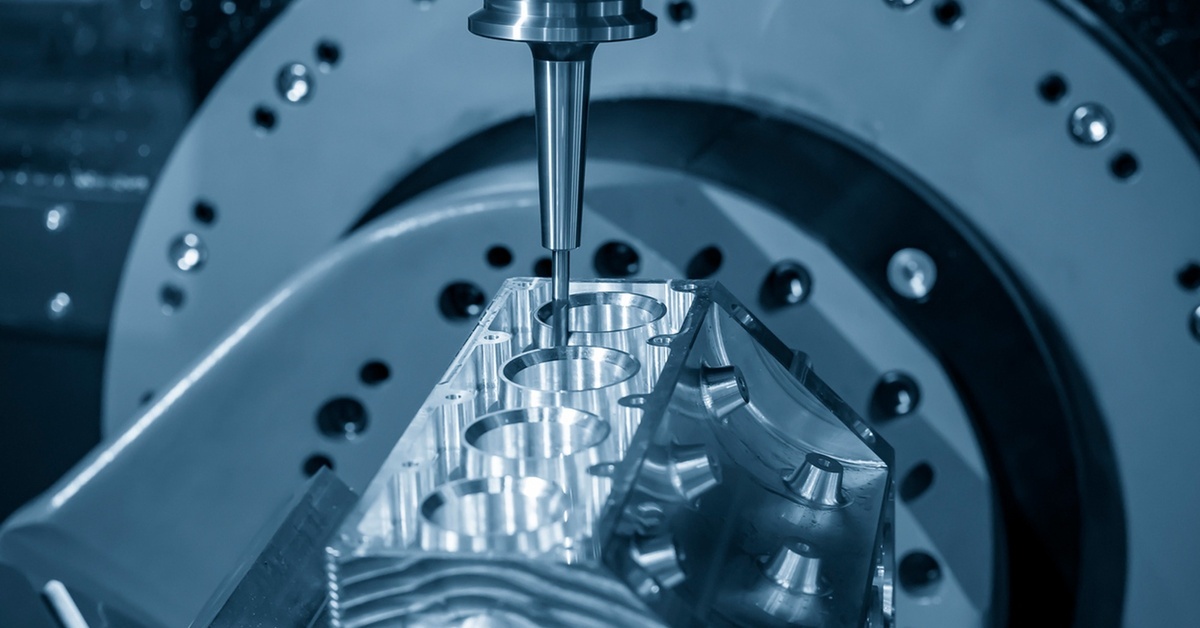

Milling is the most common CNC process, ideal for parts with complex geometries. While 3-axis machines are the workhorses of the industry, modern engineering demands more.

-

3-Axis Machining: Best for simple brackets, enclosures, and parts where only one side needs to be worked on at a time.

-

5-Axis Machining: This is where Zeometrix truly shines. By moving the cutting tool across five different axes simultaneously, we can produce parts with extreme complexity in a single setup. This is vital for aerospace components or medical implants. By eliminating the need for multiple setups, we remove "stack-up errors" caused by manual repositioning, ensuring that the geometric dimensioning and tolerancing (GD&T) remain perfect.

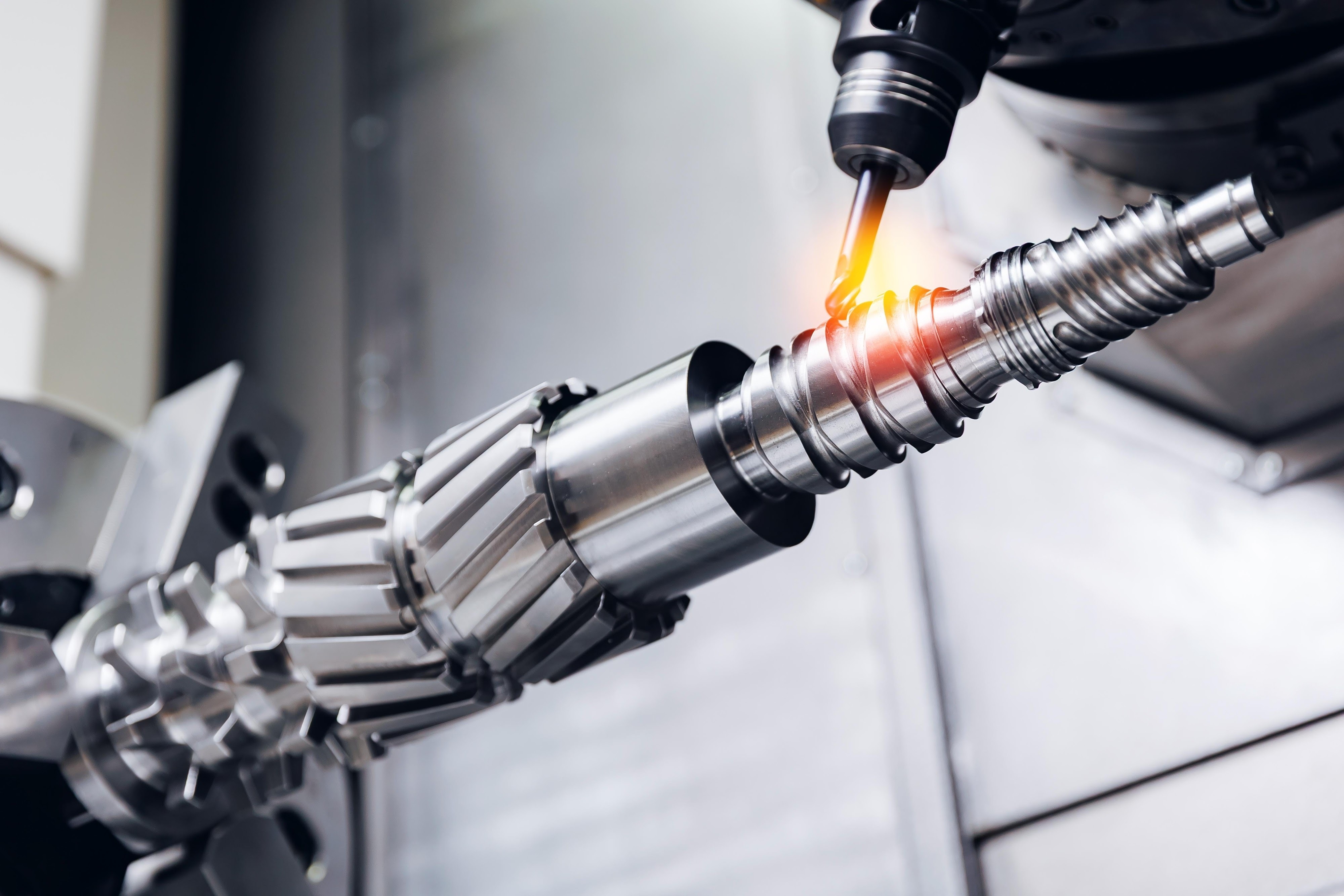

CNC Turning (Lathe)

For cylindrical components like shafts, pins, and spacers, CNC turning remains the gold standard. Our high-speed lathes at Zeometrix ensure that concentricity and surface finish meet the most stringent requirements. We routinely achieve tolerances as tight as $\pm 0.01 \text{ mm}$, ensuring a "press-fit" quality every time.

The Bridge: From Prototyping to Mass Production

One of the biggest hurdles for engineers is the "Valley of Death" between a "one-off" prototype and a production run of 10,000 units. Zeometrix specializes in this transition. Our digital-first workflow allows for rapid iterations without the typical administrative delays or massive tooling costs of traditional machine shops.

3. Materials Mastery: What We Machine

A CNC-machined part's performance is fundamentally tied to its material properties. In 2025, the variety of 'exotic' materials used in Bangalore’s tech sectors is broader than ever. At Zeometrix, we maintain a certified supply chain for custom CNC services, ensuring precision and reliability in every part we produce.

|

Material Category |

Common Examples |

Ideal Applications |

Key Properties |

|

Aluminum |

6061-T6, 7075-T6 |

Aerospace, Robotics, Heat Sinks |

Lightweight, High Machinability |

|

Stainless Steel |

304, 316L, 17-4 PH |

Medical, Marine, Food Tech |

Corrosion Resistance, High Strength |

|

Superalloys |

Titanium (Gr 5), Inconel |

Aerospace, Turbines, Implants |

High Strength-to-Weight, Heat Res. |

|

Plastics |

PEEK, Delrin (POM), ABS |

Insulators, Surgical Tools |

Biocompatible, Low Friction |

Our engineering team provides Design for Manufacturing (DfM) feedback. If we see that a design can be achieved with a more cost-effective material or a slight geometry change that reduces waste, we speak up. We don't just take orders; we act as your manufacturing consultants.

4. Serving the High-Stakes Industries of Bangalore

Bangalore is home to specialized sectors where a single micron’s error can lead to catastrophic failure. Zeometrix has tailored its operations to meet these specific compliance needs.

Aerospace and Defense

In an industry where every gram of weight matters and safety is non-negotiable, we deliver. Our 5-axis capabilities are essential for producing turbine blades, structural brackets, and drone components. We understand the necessity of documentation, providing full material traceability and CoC (Certificate of Conformance) for every batch.

Medical Technology (MedTech)

Bangalore is emerging as a global hub for medical device innovation. The demand for biocompatible parts is soaring. We machine intricate surgical instruments and orthopedic implants from Grade 5 Titanium and PEEK. In this sector, surface finish is everything; we ensure finishes where the roughness average is $R_a < 0.8 \mu\text{m}$ to prevent bacterial growth and ensure patient safety.

Robotics and EV (Electric Vehicles)

As the world moves toward automation and green energy, the need for custom robotic arms, gear housings, and battery enclosures has increased. Zeometrix supports the robotics and EV sectors with rapid turnaround times, allowing for the fast-paced testing cycles typical of Bangalore's startup culture.

5. Quality Assurance and Precision Metrics

In the world of CNC machining, "near enough" is never enough. Precision is meaningless without verification. At Zeometrix, quality isn't a final inspection box to check; it is a philosophy baked into every toolpath we program.

-

ISO 9001:2015 Standards: Our facility follows a strict quality management system to ensure that the 1,000th part is exactly like the first.

-

CMM Inspection: We utilize Coordinate Measuring Machines (CMM) to verify that the physical part matches the digital CAD file down to the smallest detail.

-

Extreme Tolerances: For critical features, we routinely achieve and verify tolerances of $\pm 0.005 \text{ mm}$.

6. The Zeometrix Workflow: From CAD to Component

We believe that getting a part machined should be as easy as ordering a product online. We’ve streamlined our workflow into four clear steps:

-

Digital Upload: You provide your 3D CAD models (STEP, IGES) and 2D drawings.

-

DfM Analysis: Within hours, our engineers review your design for "machinability." We suggest changes that could lower costs or improve structural integrity.

-

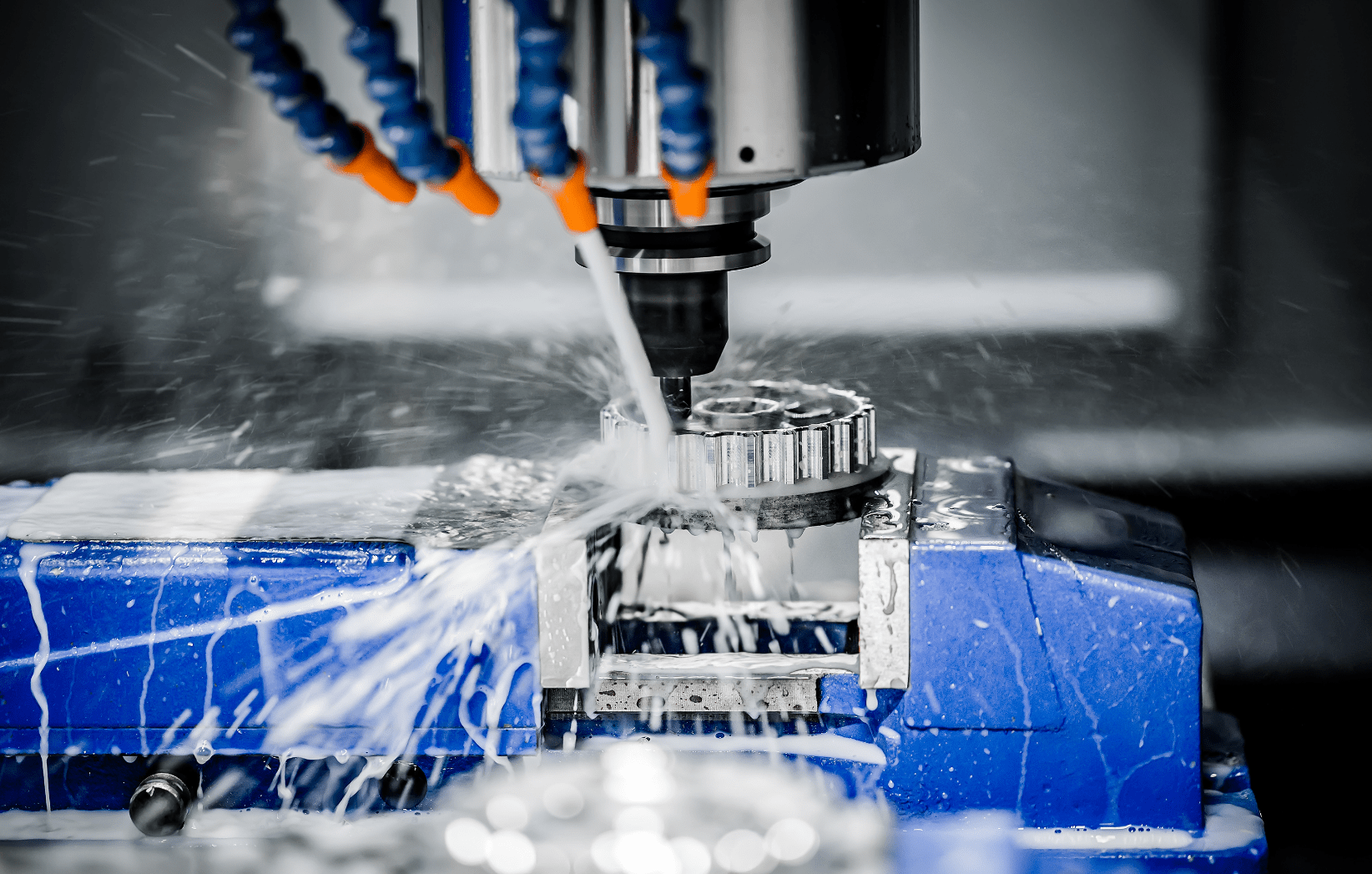

Precision Machining: Once the design is locked, our fleet of CNC machines takes over, guided by optimized toolpaths designed to minimize heat and stress on the material.

-

Inspection & Delivery: Parts undergo rigorous QC before being delivered via our local logistics network, ensuring they arrive at your facility ready for assembly.

7. Sustainability: The Future of "Green Machining"

In 2025, environmental responsibility is no longer optional. Zeometrix is committed to reducing the carbon footprint of manufacturing in Bangalore. We implement:

-

100% Metal Recycling: Every chip, shaving, and scrap piece of metal from our machines is collected, sorted, and sent for recycling.

-

MQL Technology: We use Minimal Quantity Lubrication (MQL) systems to significantly reduce the amount of chemical coolants and oils used during the machining process.

-

Energy Optimization: By using modern, energy-efficient CNC controllers and optimizing toolpaths to reduce air-cutting time, we lower the total energy consumption per part.

Conclusion

In a city that thrives on innovation, your choice of a manufacturing partner can be the difference between a successful product launch and a costly delay. Zeometrix combines the local advantages of Bangalore’s industrial expertise with world-class technology and quality standards.

Whether you're looking for a single precision prototype or a partner for high-volume production, we are here to help you build the future, one micron at a time.

Frequently Asked Questions (FAQ)

1. What is the typical lead time for CNC machining with Zeometrix?

For rapid prototypes, we can often deliver within 3 to 5 business days. For production batches (50 to 500+ units), lead times typically range from 2 to 4 weeks, depending on the complexity, material availability, and required finishing.

2. Which file formats do you accept for quoting?

We primarily work with STEP (.stp/.step) and IGES files for 3D geometry. We also strongly recommend providing a PDF 2D drawing. This is crucial for us to understand your specific tolerances, thread specifications, and surface finish requirements that aren't always captured in a 3D model.

3. Can Zeometrix handle small-batch production?

Absolutely. We specialize in "High-Mix, Low-Volume" manufacturing. Whether you need a single proof-of-concept prototype or a small batch of 50 units for a pilot launch, our setup is optimized to be cost-effective without requiring massive minimum order quantities (MOQs).

4. Do you offer post-processing services like anodizing?

Yes. We are a true one-stop shop. We provide a full suite of finishing services, including:

-

Anodizing (Type II & III) for corrosion resistance and color.

-

Powder Coating and Bead Blasting for aesthetic finishes.

-

Electroless Nickel Plating for wear resistance.

-

Laser Engraving for part identification and branding.

5. How does Zeometrix ensure the confidentiality of my designs?

Intellectual Property (IP) is your most valuable asset. We are happy to sign Non-Disclosure Agreements (NDAs) before you share any files. Furthermore, our internal data management systems are air-gapped and secured to ensure that your proprietary designs never leave our secure environment.