How a CNC Company in Bangalore Is Powering the Next Wave of Advanced Manufacturing

In the heart of India's Silicon Valley, the manufacturing landscape is undergoing a massive transformation. While Bangalore is globally recognized for its IT prowess, it has quietly emerged as a dominant force in precision engineering. If you are searching for a reliable CNC company in Bangalore, you are looking at more than just a service provider—you are looking for a strategic partner that can bridge the gap between complex digital designs and high-performance physical components.

Among the frontrunners in this industrial evolution is Zeometrix. With a focus on accuracy, scalability, and cost-efficiency, Zeometrix has established itself as a premier destination for businesses requiring top-tier CNC machining solutions. In this comprehensive guide, we explore why Bangalore is the ultimate hub for CNC services and how Zeometrix is leading the charge in 2026.

The Evolution of CNC Machining in Bangalore

Bangalore’s journey from a "Garden City" to a "Manufacturing Hub" has been fueled by its proximity to major aerospace and defense giants like HAL, ISRO, and BHEL. This ecosystem demanded a level of precision that only Computer Numerical Control (CNC) machining could provide.

Today, the city boasts thousands of machining units ranging from micro-workshops in Peenya to massive, automated facilities in Bommasandra and Jigani. A CNC company in Bangalore today doesn't just cut metal; it integrates AI-driven toolpaths, IoT monitoring, and sustainable manufacturing practices to meet global standards.

Why Choose a CNC Company in Bangalore?

-

Technical Talent Pool: Bangalore produces more engineers and skilled CNC operators than almost any other city in India. This ensures that your projects are handled by experts who understand the nuances of 5-axis machining and complex CAD/CAM software.

-

Industrial Infrastructure: With established clusters like the Peenya Industrial Estate—one of the largest in Southeast Asia—the supply chain for raw materials, heat treatment, and surface finishing is incredibly robust.

-

Cost-to-Quality Ratio: Bangalore offers a competitive edge by providing European-standard precision at Indian operational costs, making it a favorite for global OEMs looking to offshore production.

Zeometrix: Redefining Precision for a Global Market

When looking for a CNC company in Bangalore, the criteria often boil down to three things: Tolerance, Timeline, and Transparency. Zeometrix has built its reputation by excelling in all three.

Advanced Machining Capabilities

Zeometrix is not limited by the complexity of the design. By employing state-of-the-art machinery, the company provides:

-

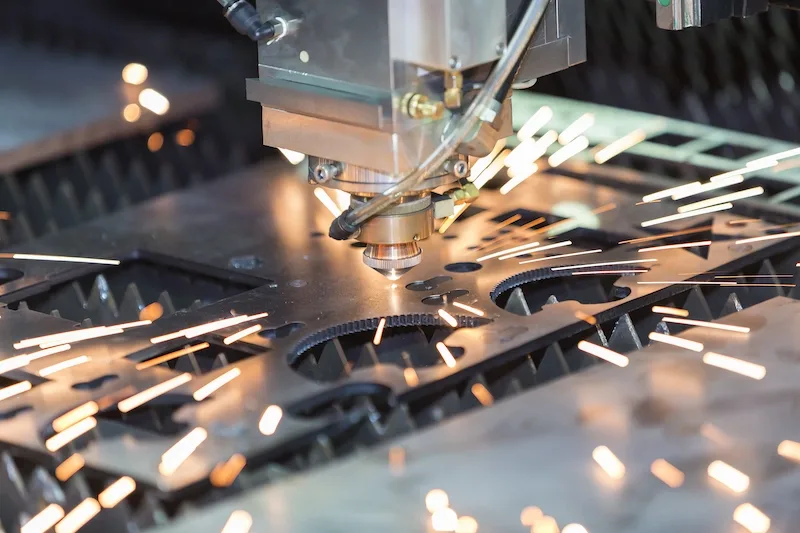

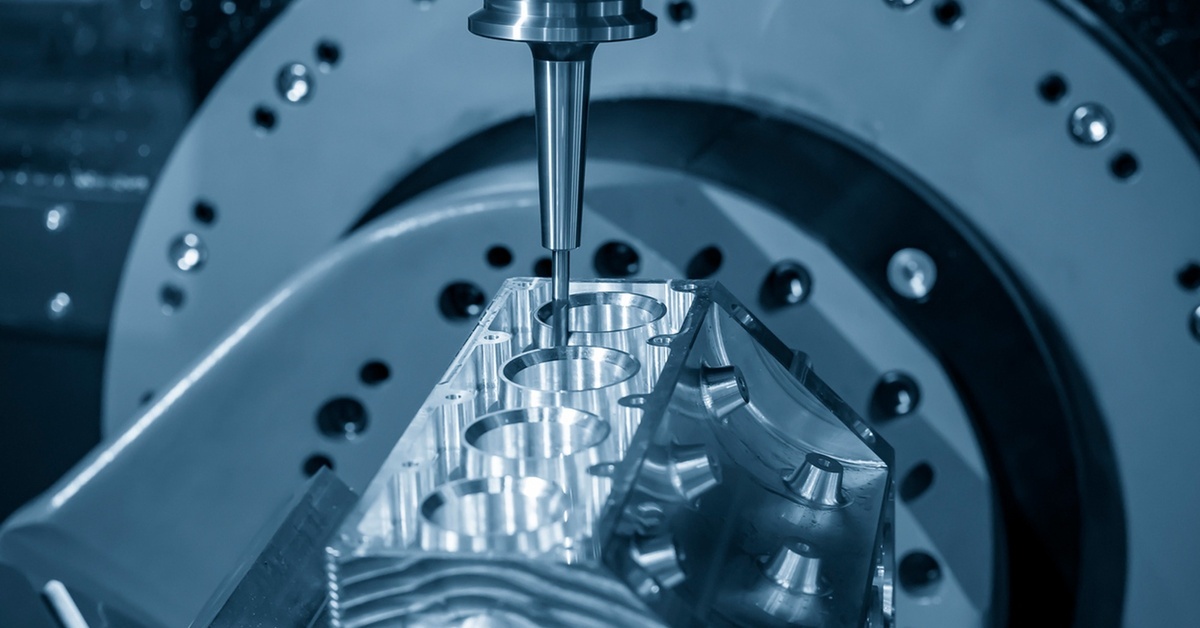

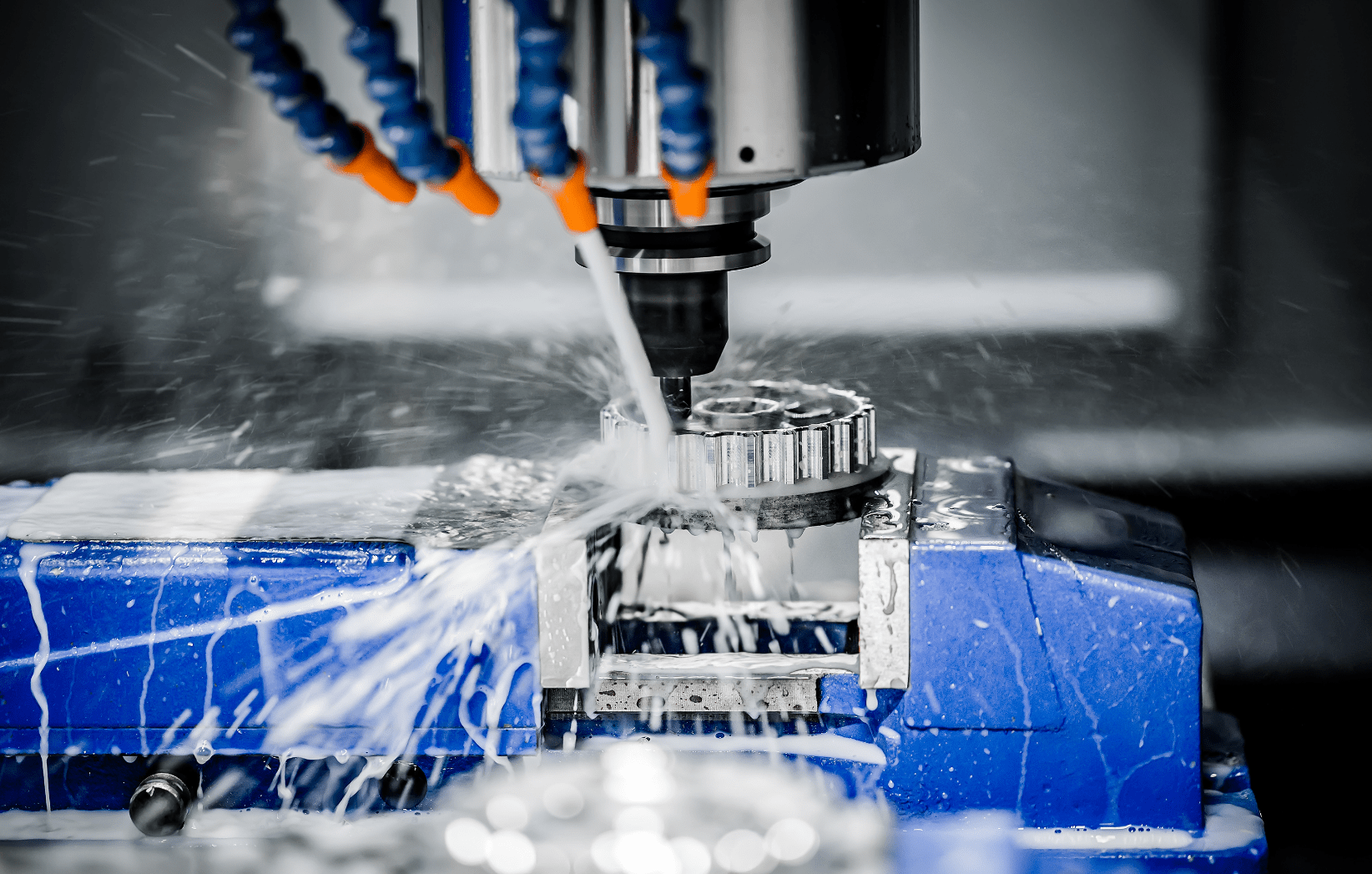

CNC Milling: Utilizing 3, 4, and 5-axis vertical machining centers (VMC) to create intricate geometries.

-

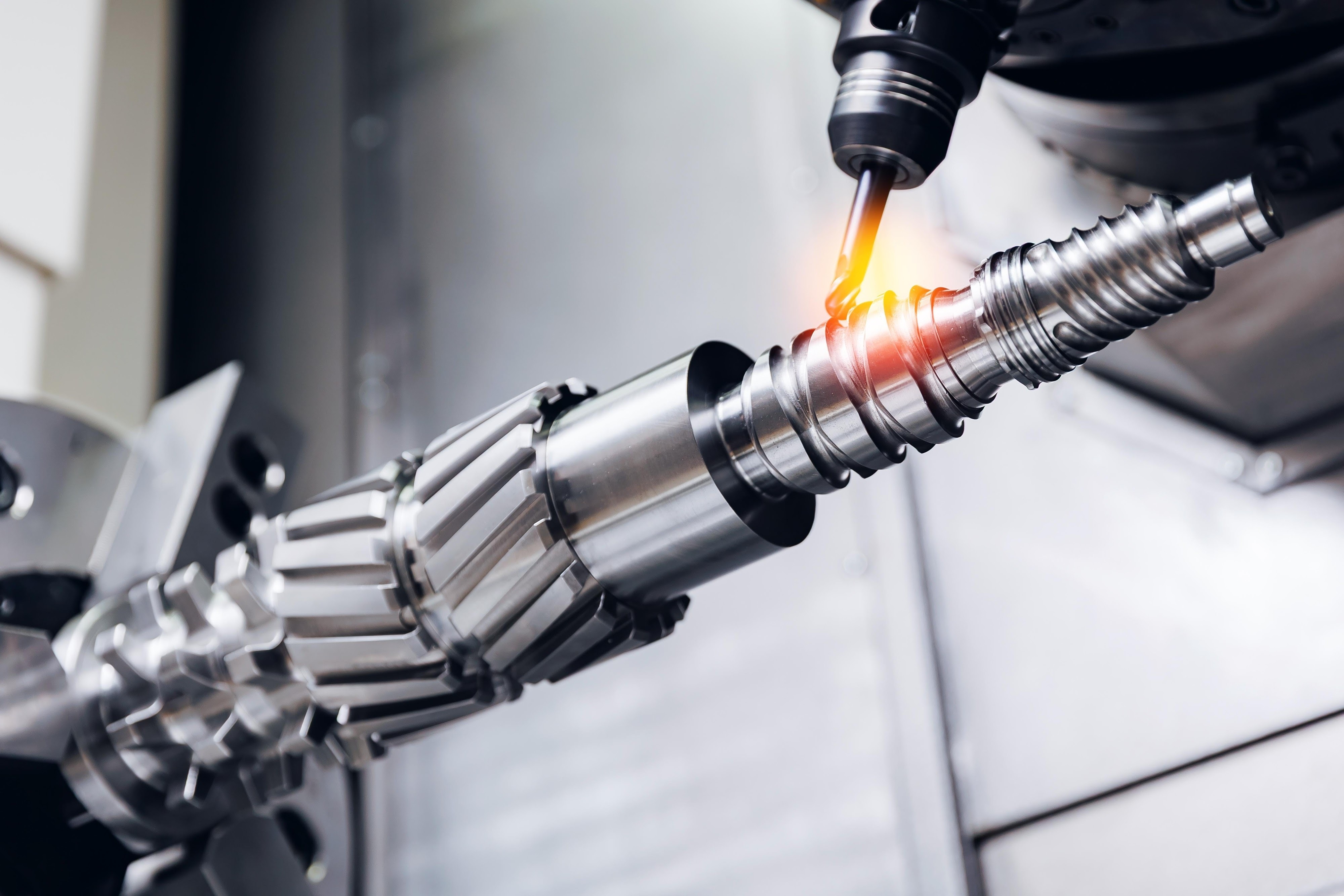

CNC Turning: High-speed lathes for cylindrical parts with micron-level accuracy.

-

Wire EDM & Grinding: For parts requiring extreme surface finishes and sharp internal corners.

-

Prototyping to Mass Production: Whether you need a single "proof of concept" or a batch of 10,000 units, the facility is optimized for flexibility.

Materials Expertise

A hallmark of a versatile CNC partner is the ability to work with diverse materials. Zeometrix handles:

-

Metals: Aluminum (6061, 7075), Stainless Steel (304, 316), Titanium, Brass, and Tool Steels.

-

Plastics: PEEK, Delrin, ABS, and Polycarbonate for medical and electronic applications.

-

Alloys: Inconel and specialized aerospace alloys.

Key Industries Served by Zeometrix in Bangalore

The versatility of production cnc machining allows Zeometrix to serve a wide array of high-stakes industries:

1. Aerospace and Defense

In an industry where a fraction of a millimeter can be the difference between success and failure, Zeometrix delivers flight-critical components, sensor housings, and structural brackets that meet stringent AS9100-level expectations.

2. Medical Device Manufacturing

Bangalore is a growing hub for MedTech. Zeometrix supports this sector by producing surgical instruments, orthopedic implants, and diagnostic equipment housings that require biocompatible materials and ultra-smooth finishes.

3. Automotive and EV

With the shift toward Electric Vehicles (EVs), there is a massive demand for lightweight aluminum components and battery housings. As a leading CNC company in Bangalore, Zeometrix helps automotive startups and giants alike with rapid prototyping and powertrain components.

4. Electronics and Robotics

From heat sinks for high-power electronics to custom chassis for industrial robots, the precision offered by Zeometrix ensures that delicate electronic assemblies fit perfectly every time.

The Zeometrix Advantage: Why We Stand Out

In a crowded market, Zeometrix differentiates itself through a "Quality First" philosophy.

1. Digital Twin and Simulation

Before a single chip of metal is cut, Zeometrix utilizes digital twin technology to simulate the machining process. This identifies potential collisions, optimizes toolpaths for speed, and ensures that the final part matches the CAD model perfectly.

2. Rigorous Quality Control

Precision is nothing without verification. The facility is equipped with Coordinate Measuring Machines (CMM), optical comparators, and digital height gauges. Every batch comes with comprehensive inspection reports, ensuring full traceability.

3. Sustainable Machining

In 2026, being a top CNC company in Bangalore means being environmentally responsible. Zeometrix employs Minimum Quantity Lubrication (MQL) and advanced coolant recycling systems to reduce waste and energy consumption.

Navigating the CNC Landscape in Bangalore (2026 Trends)

As we move through 2026, several trends are defining the future of machining in the city. Zeometrix is at the forefront of these shifts:

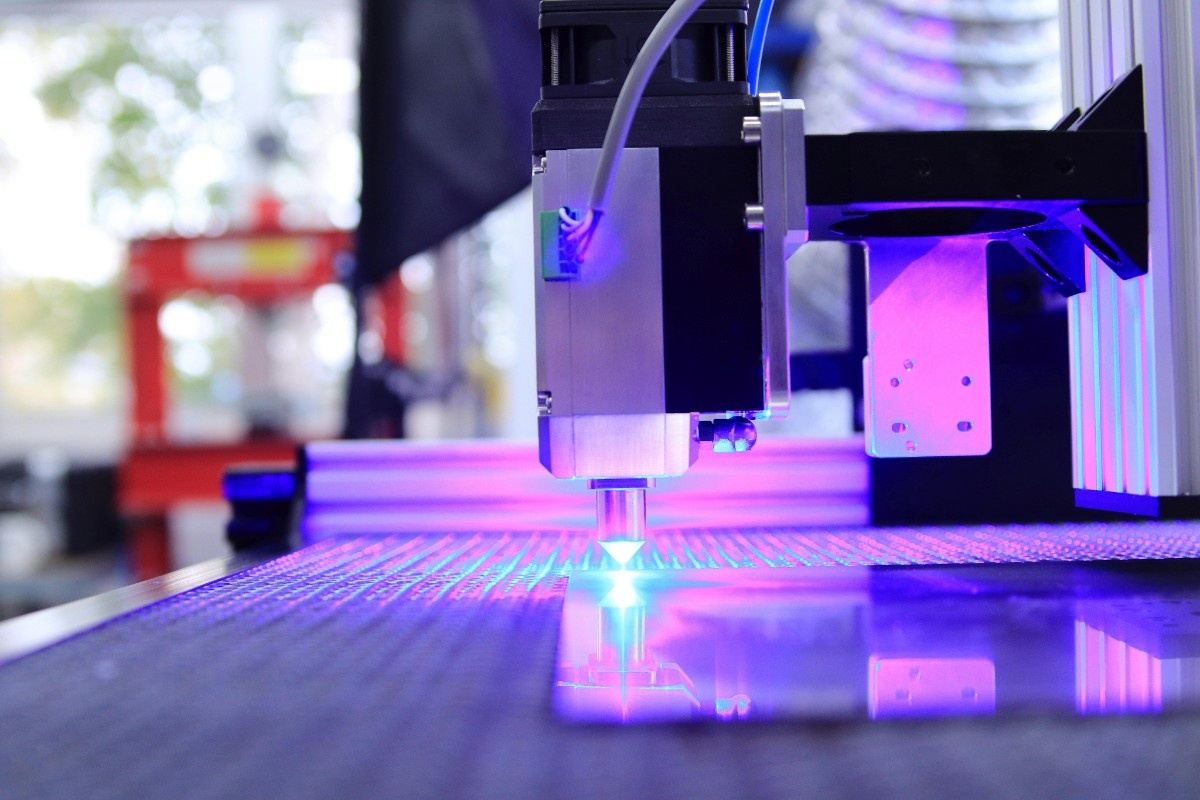

AI-Native Machining

Artificial Intelligence is no longer a buzzword. Zeometrix integrates AI into its machine controllers to adjust feed rates and speeds in real-time based on sensor feedback, reducing tool wear and improving surface quality.

Hybrid Manufacturing

The convergence of 3D printing (additive) and CNC machining (subtractive) is a game-changer. Zeometrix uses hybrid workflows to create "near-net-shape" parts via 3D printing and then finishes critical features with high-precision CNC milling, saving time and material.

Lights-Out Manufacturing

To meet the "fast turnaround" demands of modern industry, Zeometrix utilizes robotic loading and unloading systems. This allows machines to run unattended through the night, significantly compressing lead times for large orders.

How to Start Your Project with Zeometrix

Partnering with a CNC company in Bangalore should be a seamless experience. Zeometrix has streamlined the procurement process into four simple steps:

-

Inquiry & DFM Analysis: Submit your 3D models (STEP, IGES, or SolidWorks files). Our engineers perform a "Design for Manufacturability" (DFM) analysis to suggest cost-saving optimizations.

-

Quoting: Receive a detailed quote including material costs, machining time, and post-processing (anodizing, plating, etc.).

-

Production: Once approved, your project enters our digital pipeline. You receive updates as your parts move through milling, turning, and inspection.

-

Delivery: Parts are carefully packaged and delivered across Bangalore or shipped globally with all necessary certifications.

Conclusion

Finding the right CNC company in Bangalore is the most critical decision you will make for your product’s lifecycle. The city offers an unparalleled ecosystem of talent and technology, but it is the individual shop’s commitment to precision that makes the difference.

Zeometrix combines the agility of a startup with the technical rigor of a global manufacturer. By investing in 5-axis technology, AI-driven processes, and a world-class engineering team, we ensure that your designs are realized with the highest level of accuracy. Whether you are an aerospace engineer in need of a complex turbine component or a hardware startup building the next big consumer device, Zeometrix is your partner in precision.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for a CNC project at Zeometrix?

For standard prototypes, we typically deliver within 3 to 7 business days. For production batches, the lead time depends on the volume and complexity, but our automated "lights-out" machining capabilities allow us to be significantly faster than traditional shops.

2. Can Zeometrix help with the design of my part?

While we are primarily a manufacturing company, we offer extensive Design for Manufacturability (DFM) support. We can suggest changes to your design that will make it easier and more cost-effective to machine without compromising functionality.

3. What tolerances can you achieve?

As a leading CNC company in Bangalore, we regularly achieve tolerances as tight as $\pm 0.005mm$ (5 microns) depending on the material and part geometry. Our CMM equipment ensures every part is verified to your specific requirements.

4. Do you handle post-processing services like anodizing or powder coating?

Yes. Zeometrix is a one-stop solution. We handle everything from the initial machining to post-processing, including anodizing, bead blasting, powder coating, plating, and heat treatment, through our certified partner network in Bangalore.

5. How do I know my intellectual property (IP) is safe?

At Zeometrix, we treat IP with the utmost seriousness. we are happy to sign Non-Disclosure Agreements (NDAs) before any drawings are shared, and our digital infrastructure is secured to prevent unauthorized access to your proprietary designs.