Precision CNC Machining Services in Bangalore for High-Performance Components: A Zeometrix Specialty

Bangalore, the esteemed 'Silicon Valley of India,' is renowned globally not just as an epicenter for IT and digital innovation, but also as a powerhouse for precision engineering and advanced manufacturing. In an era where global industries—including aerospace, medical devices, defense, and high-performance automotive—demand components with near-flawless accuracy and absolute reliability, Zeometrix stands at the forefront. Zeometrix's precision CNC machining services in Bangalore, including CNC machining services in Bangalore offering aluminum and steel machining, have emerged as critical strategic partners for both global and domestic manufacturers seeking to build the next generation of high-performance parts.

This domain transcends mere metal cutting; at Zeometrix, it is the highly sophisticated process of transforming complex digital designs into physical realities with dimensional tolerances often measured in microns. For technology companies and original equipment manufacturers (OEMs) requiring reliable, scalable, and cost-effective precision component production, Zeometrix offers a unique and compelling combination of deeply skilled labor, cutting-edge technology, and a robust, vertically integrated industrial ecosystem right here in Bangalore.

The Foundation of Excellence: Defining Precision CNC Machining at Zeometrix

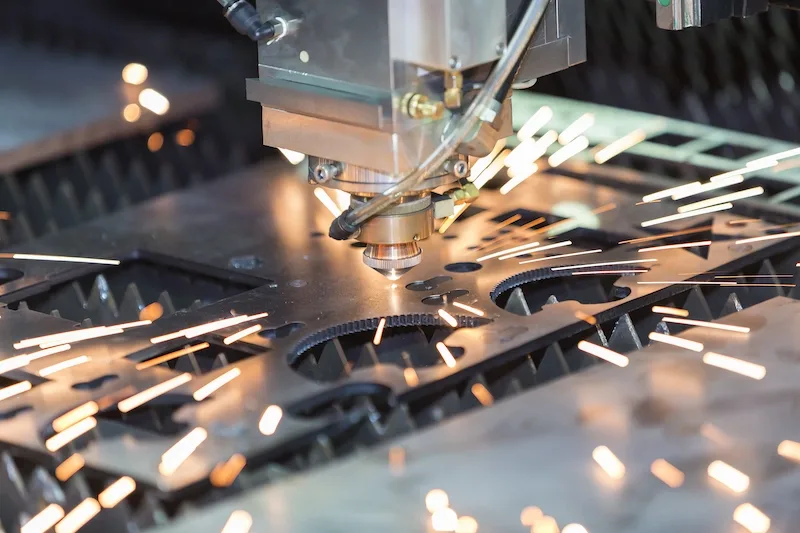

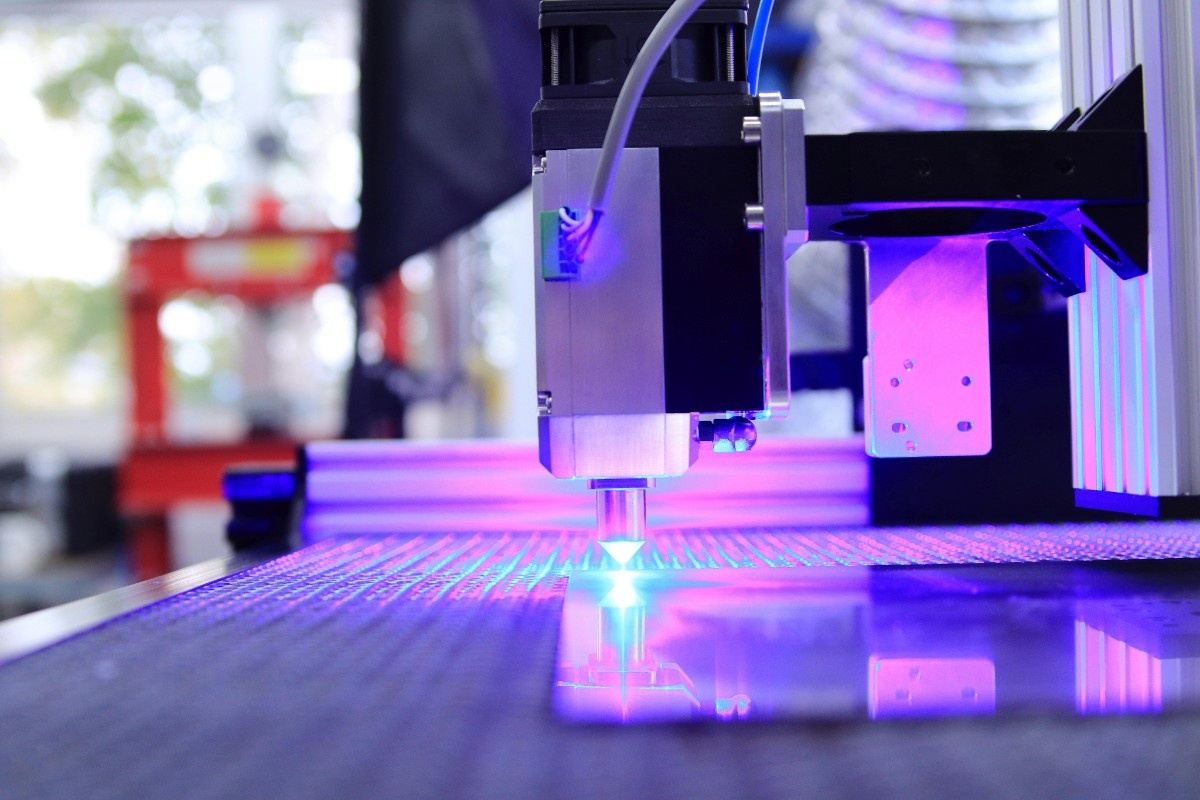

Precision CNC machining is a sophisticated subtractive manufacturing method that uses computer-controlled machine tools (mills and lathes) to carve material from a raw stock, guided by detailed computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. What critically sets Zeometrix's precision machining apart is its uncompromising commitment to achieving extremely tight tolerances (often $< \pm 0.01$ mm, or 10 microns, or less) and delivering superior surface finishes.

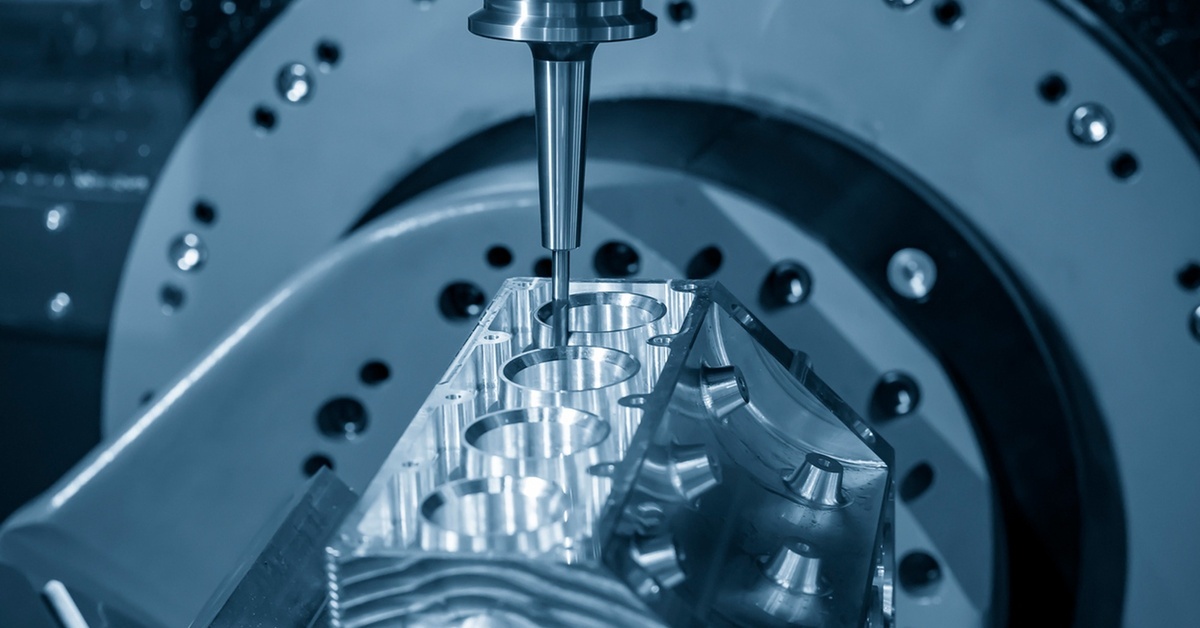

It is the indispensable manufacturing methodology of choice when component failure is entirely unacceptable. Consider a critical component manufactured by Zeometrix: a high-pressure valve body, a custom spinal implant, or a complex radar housing. Each must perform exactly as mathematically designed, which necessitates a level of dimensional consistency, repeatability, and accuracy that older, conventional machining techniques simply cannot deliver or guarantee at scale.

The Technological Edge: Multi-Axis Capabilities and Beyond

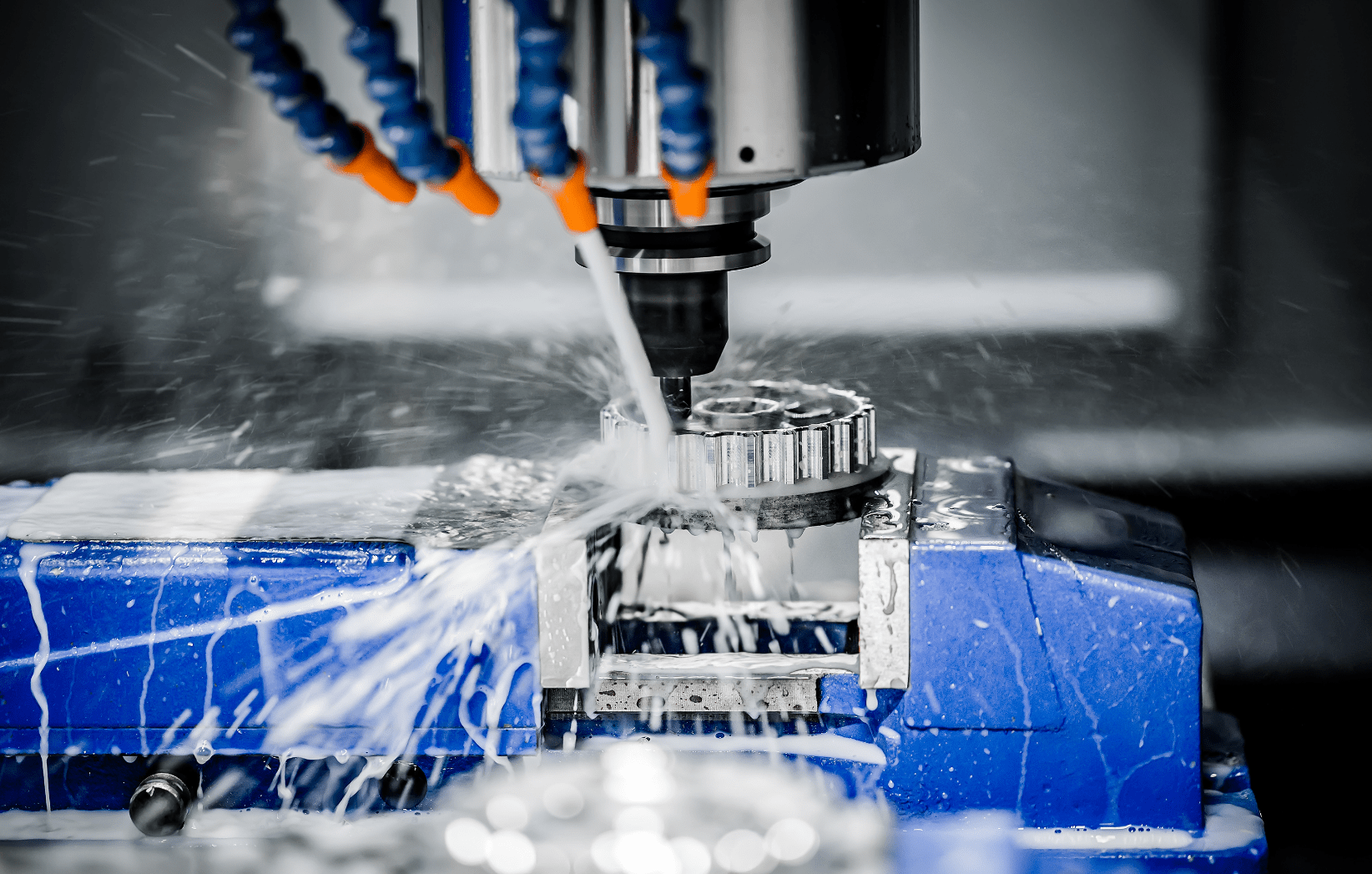

Modern, high-performance components frequently feature complex, non-prismatic, and deeply contoured geometries that necessitate machining from numerous angles. Zeometrix's workshops are equipped with the most advanced machinery to proficiently handle this complexity:

- 3-Axis Machining: The foundational workhorse, highly effective for simpler geometries.

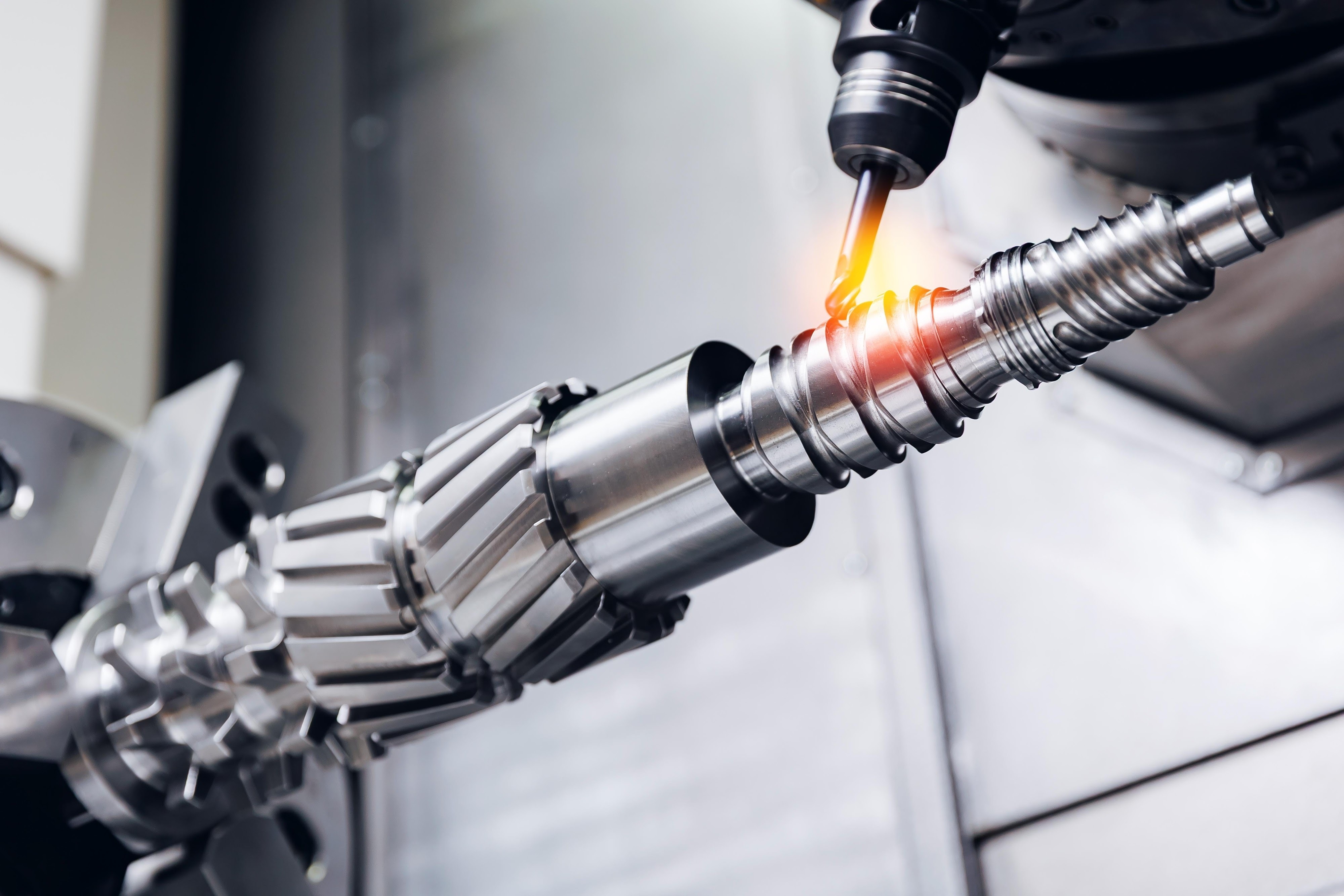

- 4-Axis Machining: Integrates a rotational axis, significantly enhancing efficiency and maintaining better concentricity for parts requiring indexing.

- 5-Axis Machining: The pinnacle of capability, utilized by Zeometrix for creating highly intricate, organic, and complex shapes—such as impellers, blisks, and deep cavity molds—in a single, continuous setup. This single-setup approach minimizes cumulative tolerance stack-up errors, which is absolutely vital for flight-critical aerospace components and sophisticated medical devices.

Furthermore, Zeometrix utilizes advanced techniques like High-Speed Machining (HSM) and incorporates real-time thermal compensation systems to counteract minute thermal expansion effects, ensuring precision is maintained even during prolonged operational cycles.

Bangalore: Zeometrix's Strategic Precision Manufacturing Hub

Bangalore's unique industrial environment and infrastructure make it an unparalleled location for Zeometrix's precision CNC services, driven by several major competitive advantages:

1. A Robust and Integrated Industrial Ecosystem

Zeometrix, strategically located within Bangalore’s major industrial zones, benefits from a densely concentrated ecosystem of high-end fabrication units and specialized ancillary services. This facilitates immediate, localized access to a full value chain: certified raw materials, specialized tooling suppliers, advanced non-destructive testing (NDT) facilities, complex heat treatment services, and independent testing labs. This proximity leads to a significantly faster, more transparent, and more reliable production cycle, drastically reducing multi-stage logistic delays.

2. A Deep and Highly Skilled Labor Pool

As a premier national center for advanced engineering education, Bangalore naturally feeds Zeometrix a continuous and high-quality supply of expertly trained CNC operators, CAD/CAM programmers, and seasoned manufacturing engineers. These Zeometrix professionals are not merely machine operators; they are skilled engineers adept at manipulating advanced multi-axis machines, executing complex G-code programming, optimizing toolpaths for exotic materials, and rigorously adhering to stringent international quality control protocols. This highly technical expertise is a critical differentiator, ensuring consistent, high-yield, and high-quality output that meets global standards.

3. Cost Efficiency Coupled with Uncompromising Quality

Compared to legacy manufacturing economies, Zeometrix's CNC services leverage efficient local logistics and competitive labor rates to offer a remarkably competitive cost structure. This advantage allows Zeometrix to provide globally cost-effective manufacturing solutions without requiring any compromises on the fundamental requirements of quality or precision. Zeometrix also specializes in affordable CNC machining services in Bangalore for small-batch production, making it an ideal partner for businesses seeking cost-efficient solutions without sacrificing accuracy. This efficiency is particularly valuable for companies needing rapid prototyping, rigorous iterative design validation, and high-volume, continuous production runs.

4. Specialization in Difficult-to-Machine Materials

The sustained presence of India's major aerospace and defense research organizations in Bangalore has driven Zeometrix to specialize in machining exotic, high-strength, and difficult-to-machine materials. This capability is fundamental for modern high-performance parts. Zeometrix has proven expertise in:

- Aerospace: Expertise in Titanium alloys (e.g., Ti-6Al-4V) and nickel-based superalloys like Inconel 718.

- Medical: Proficiency in bio-compatible materials such as 316L Stainless Steel and specific medical-grade Titanium and PEEK plastic.

Serving Critical Industries: Component Applications with Zeometrix

Zeometrix's precision CNC machining services are strategically aligned to cater to the sectors that possess the highest and most uncompromising performance and quality demands.

Aerospace and Defense

This sector requires components that are simultaneously extremely lightweight and structurally strong. Zeometrix ensures absolute precision, material traceability, and process control for these critical parts.

- Typical Components: Turbine discs and blades, complex engine structural casings, hydraulic manifold blocks, and critical sensor mounts.

- Key Requirement: Strict adherence to AS9100 certification and NADCAP accreditation.

Medical and Healthcare

Medical devices and surgical implants demand bio-compatible materials, flawlessly smooth surface finishes, and zero deviation in dimension. Zeometrix ensures tolerances here are held to the tightest global standards.

- Typical Components: Orthopedic implants, custom surgical instruments, and housings for advanced imaging equipment.

- Key Requirement: Strict compliance with ISO 13485:2016 (Quality Management System for Medical Devices).

Automotive and Electric Vehicles (EV)

The industry's transition requires innovative thermal management solutions and highly durable powertrain components. Zeometrix provides the precision needed for these next-gen systems.

- Typical Components: Precision gearbox housings, high-efficiency thermal cooling plates for battery packs, and customized braking system parts.

- Key Requirement: Adherence to the IATF 16949:2016 quality standard.

The Zeometrix Seal of Quality: Global Certifications

At Zeometrix, quality assurance is non-negotiable. We operate rigorously under globally recognized quality standards, which validate our commitment to predictable process control and repeatable, high-quality output:

|

Standard |

Industry Focus |

What it Ensures |

|

ISO 9001:2015 |

General Manufacturing |

Foundational global standard for process-based Quality Management Systems. |

|

AS 9100 |

Aerospace & Defense |

Critical quality management system for organizations supplying aviation, space, and defense components. |

|

ISO 13485 |

Medical Devices |

QMS tailored for the design, development, and manufacture of medical devices. |

|

NADCAP |

Aerospace Special Processes |

Accreditation for verifying specialized processes like heat treatment and NDT. |

Choosing Zeometrix minimizes supply chain risk, guarantees robust process control, and ensures that every manufactured part conforms precisely to the necessary, repeatable specifications required for high-performance operation.

Conclusion: Driving the Future with Zeometrix Precision

Zeometrix's precision CNC machining services in Bangalore have solidified their position as an indispensable and strategic link in the global supply chain for complex, high-performance components. We offer far more than just a reduction in manufacturing cost; we deliver unmatched dimensional accuracy, profound material versatility, and complex geometric capability that is underpinned by a highly skilled engineering workforce and powered by the latest multi-axis and automated machinery.

For technology-driven companies across the globe, partnering with Zeometrix is a strategic decision that promises to enhance design-to-production efficiency, guarantee rigorous international quality compliance, and provide the necessary scalability and reliability to meet the most dynamic and challenging market demands. Zeometrix is also recognized for its fast-turnaround CNC machining services in Bangalore for prototype development, enabling rapid iteration and early testing that accelerates product launch timelines. As India continues to ascend and mature as a major global manufacturing hub, the precision engineering sector led by Zeometrix will undoubtedly remain at the cutting edge, transforming intricate digital blueprints into the reliable, certified, and high-performance physical parts that power the next generation of global innovation.

Frequently Asked Questions (FAQs) About Zeometrix CNC Services

1. What are the typical achievable tolerances for Precision CNC Machining at Zeometrix?

Achievable tolerances depend on the specific project, but Zeometrix routinely achieves tolerances as tight as $\pm 0.01$ mm (10 microns). For specialized projects in the medical and optics sectors, our thermal-compensated 5-axis machines can maintain tolerances below $\pm 5$ microns, meeting the most stringent global specifications.

2. What essential technical file formats are required to request a formal quote from Zeometrix?

We require a fully defined 3D CAD model (preferably in STEP or IGES format) for geometry definition. Crucially, this must be accompanied by a corresponding 2D engineering drawing (PDF) that specifies all required GD&T callouts, critical dimensions, material composition, and final surface finish specifications.

3. What exotic and difficult-to-machine materials does Zeometrix specialize in?

Zeometrix has extensive experience with high-performance materials including aerospace-grade Titanium (Ti-6Al-4V), nickel-based superalloys like Inconel 718 (for high-heat/stress applications), high-strength aluminum alloys (7075), and high-performance engineering plastics like PEEK and Ultem.

4. What value-added services does Zeometrix offer beyond the core machining process?

Zeometrix provides a complete, end-to-end service package. This includes initial Design for Manufacturability (DFM) review, various surface treatments (anodizing, plating, passivation), in-house heat treatment, guaranteed Coordinate Measuring Machine (CMM) quality inspection and reporting, and final assembly or sub-assembly services.

5. Which global quality standards does Zeometrix adhere to for highly regulated projects?

For highly regulated industries, Zeometrix holds certifications including ISO 9001:2015 (general QMS), AS 9100 (Aerospace & Defense), ISO 13485 (Medical Devices), and we use facilities with NADCAP accreditation for special processes like heat treatment, ensuring absolute compliance and traceability.