The Ultimate Guide to CNC Machining in Bangalore: Precision Engineering with Zeometrix

In the heart of India's industrial evolution, Bangalore has transitioned from being the "Garden City" to the "Silicon Valley," and now, the undisputed "Precision Hub of Asia." For any business involved in hardware development, whether a global aerospace giant or a deep-tech startup, the phrase CNC Machining in Bangalore represents a gold standard of quality, speed, and technical ingenuity.

As we navigate through 2026, the manufacturing landscape is no longer about just cutting metal. It is about digital integration, material science, and supply chain agility. At the center of this transformation is Zeometrix, a company that has redefined what it means to be a manufacturing partner in the modern era. In this comprehensive guide, we explore the ecosystem of CNC machining in Bangalore and how Zeometrix is leading the charge toward a more efficient, precise future.

The Industrial DNA of Bangalore

To understand why CNC machining flourishes here, one must look at the city's unique industrial geography. Bangalore is home to several massive industrial estates like Peenya, Jigani, Bommasandra, and Whitefield.

Peenya, often cited as one of the largest industrial hubs in South Asia, houses thousands of small-scale precision workshops. However, as the demand for complexity grew, the need for more sophisticated players like Zeometrix emerged. Today, Bangalore accounts for a significant portion of India’s machine tool production and high-precision component exports. The city offers:

-

A Skilled Talent Pool: A massive concentration of mechanical and software engineers.

-

Infrastructure: World-class testing labs, material suppliers, and logistics networks.

-

A Culture of Quality: Decades of experience serving the Indian Space Research Organisation (ISRO) and Hindustan Aeronautics Limited (HAL).

Zeometrix: Bridging the Gap Between Digital and Physical

While there are hundreds of CNC shops in Bangalore, Zeometrix has carved out a niche by solving the most common pain point in manufacturing: The Communication Gap. Traditional manufacturing often involves endless emails, manual quoting, and vague timelines. Zeometrix has disrupted this by introducing a digital-first approach. They act as a sophisticated bridge, providing the speed of a startup with the heavy-duty capabilities of a Tier-1 factory.

The Zeometrix Advantage:

-

Instant Technical Feedback: Their platform allows for rapid assessment of CAD designs.

-

Diverse Capabilities: From 3-axis and 5-axis milling to CNC turning and sheet metal fabrication.

-

End-to-End Management: They handle everything from raw material procurement to post-processing and assembly.

Critical Services Offered by Zeometrix

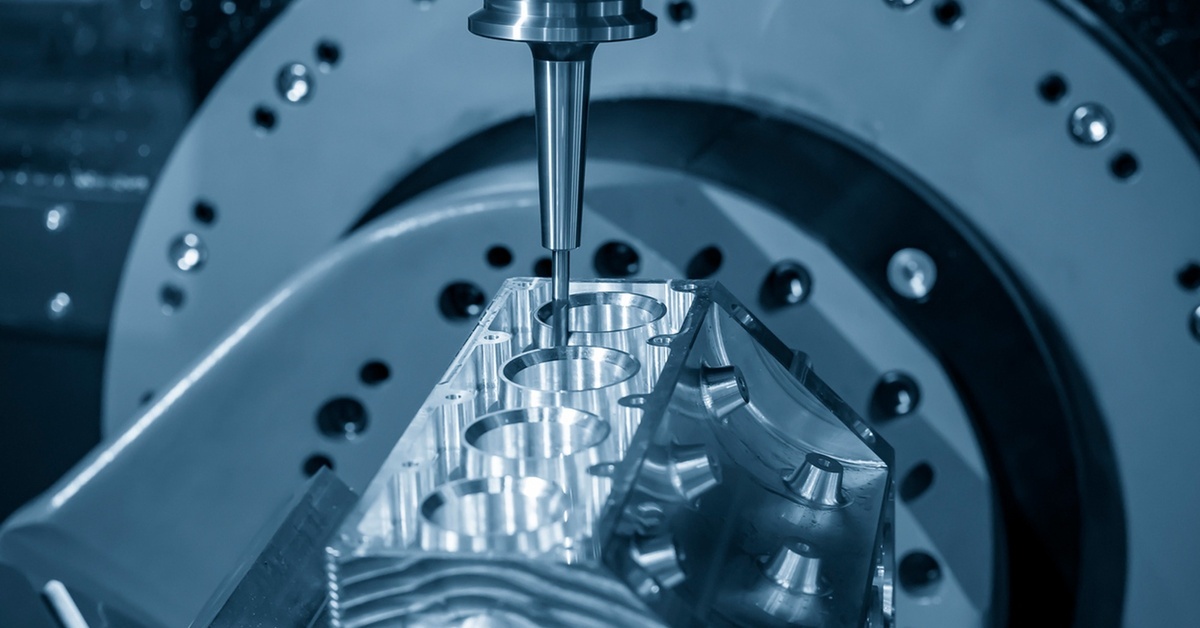

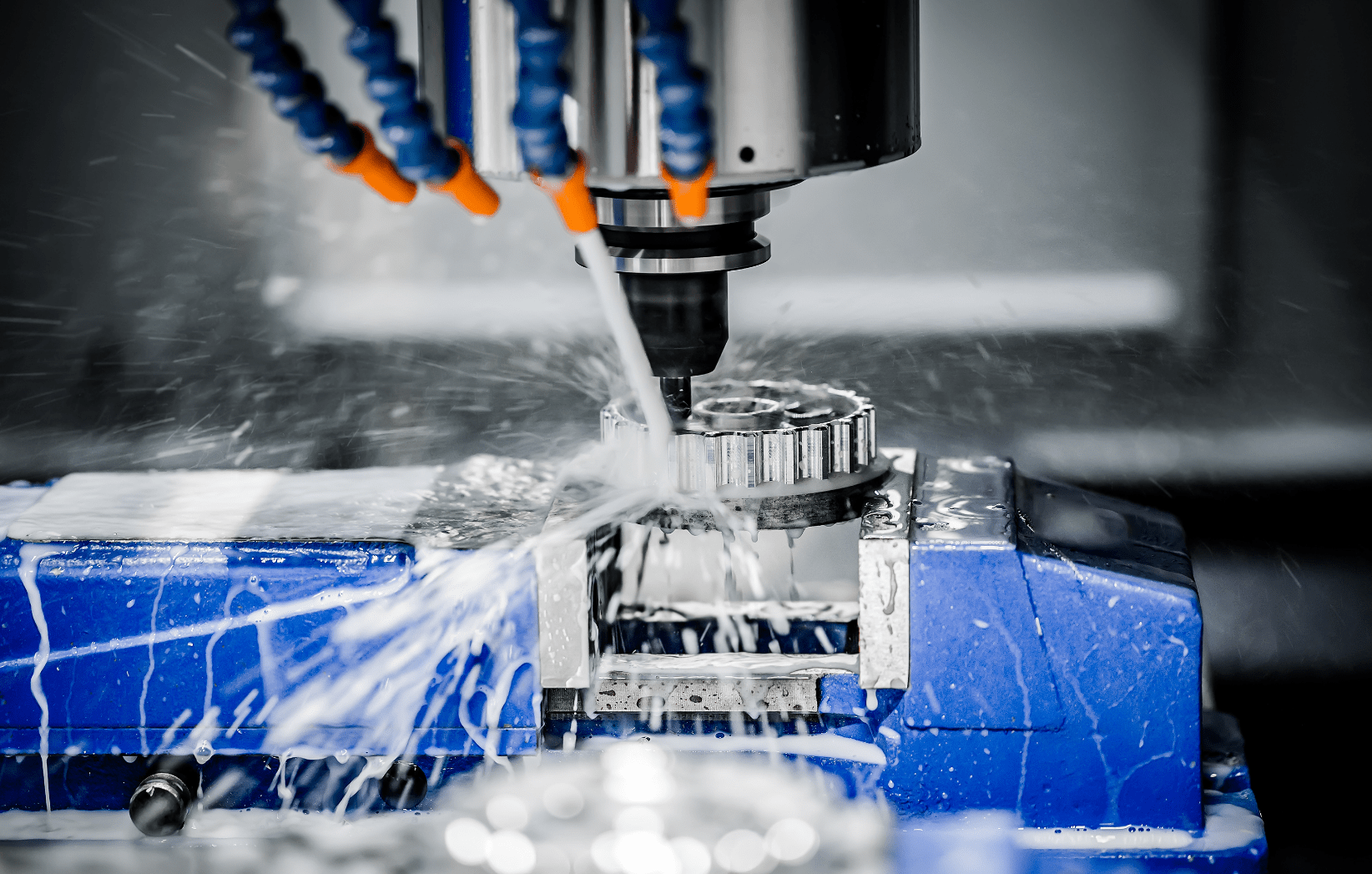

1. High-Precision CNC Milling

Zeometrix utilizes state-of-the-art Vertical Machining Centers (VMC). Milling is essential for parts with complex geometries. By using multi-axis machines, Zeometrix can produce intricate components for drone frames, medical device housings, and heat sinks with extreme accuracy.

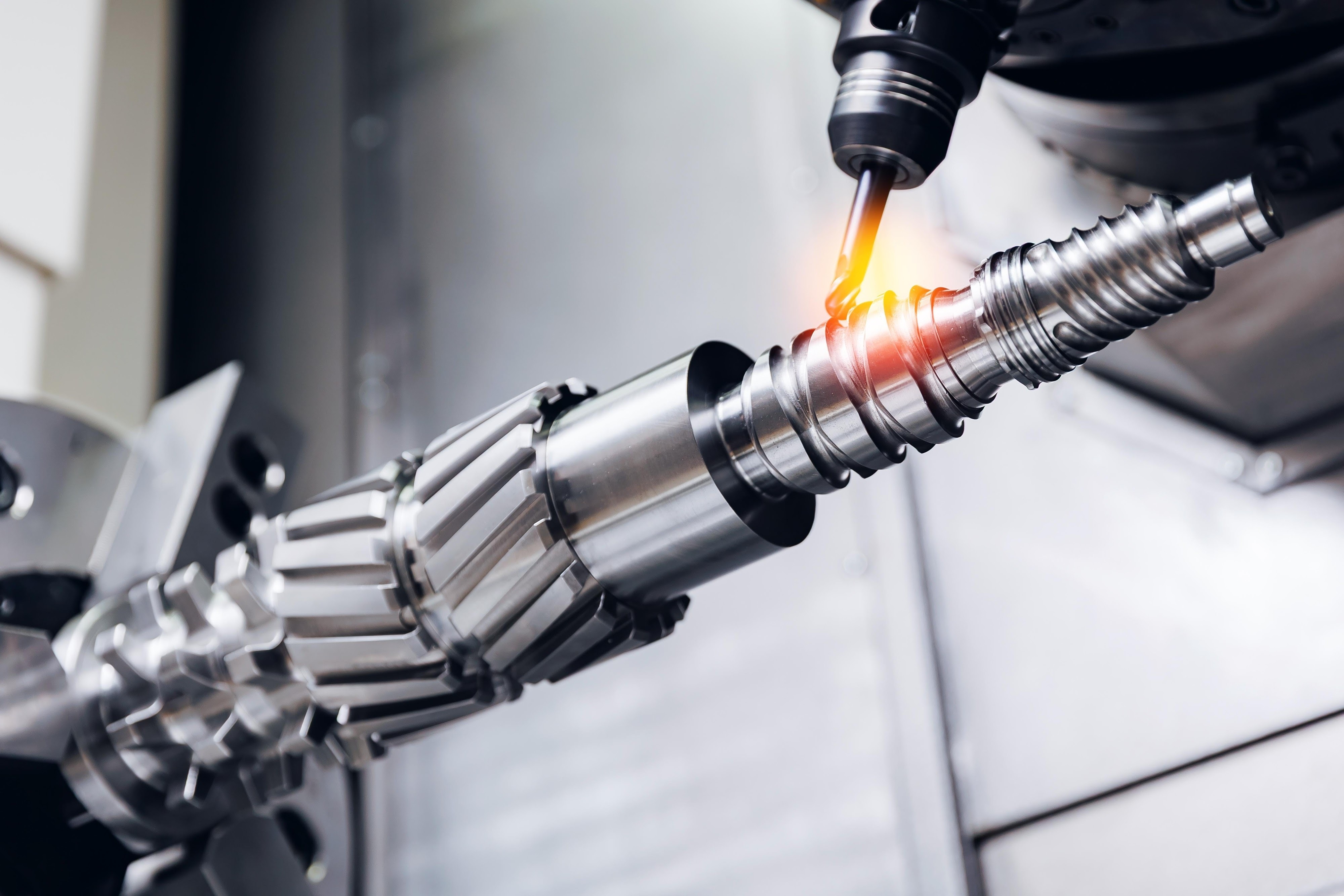

2. CNC Turning (Lathe)

For cylindrical components like shafts, bushings, and fasteners, Zeometrix’s CNC turning services provide a high-speed solution. Their lathes can handle a wide variety of diameters, ensuring that even the smallest connector or the largest industrial axle meets the required tolerance.

3. Rapid Prototyping

In 2026, the "Time-to-Market" is the most critical metric for any business. Zeometrix specializes in rapid prototyping, allowing engineers to receive physical parts in hand within days. This allows for iterative testing, reducing the risk of expensive errors during mass production.

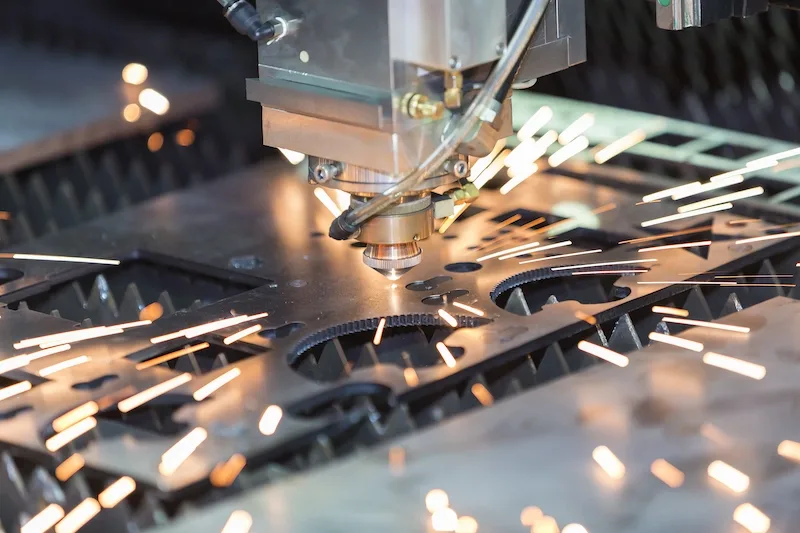

4. Sheet Metal Fabrication

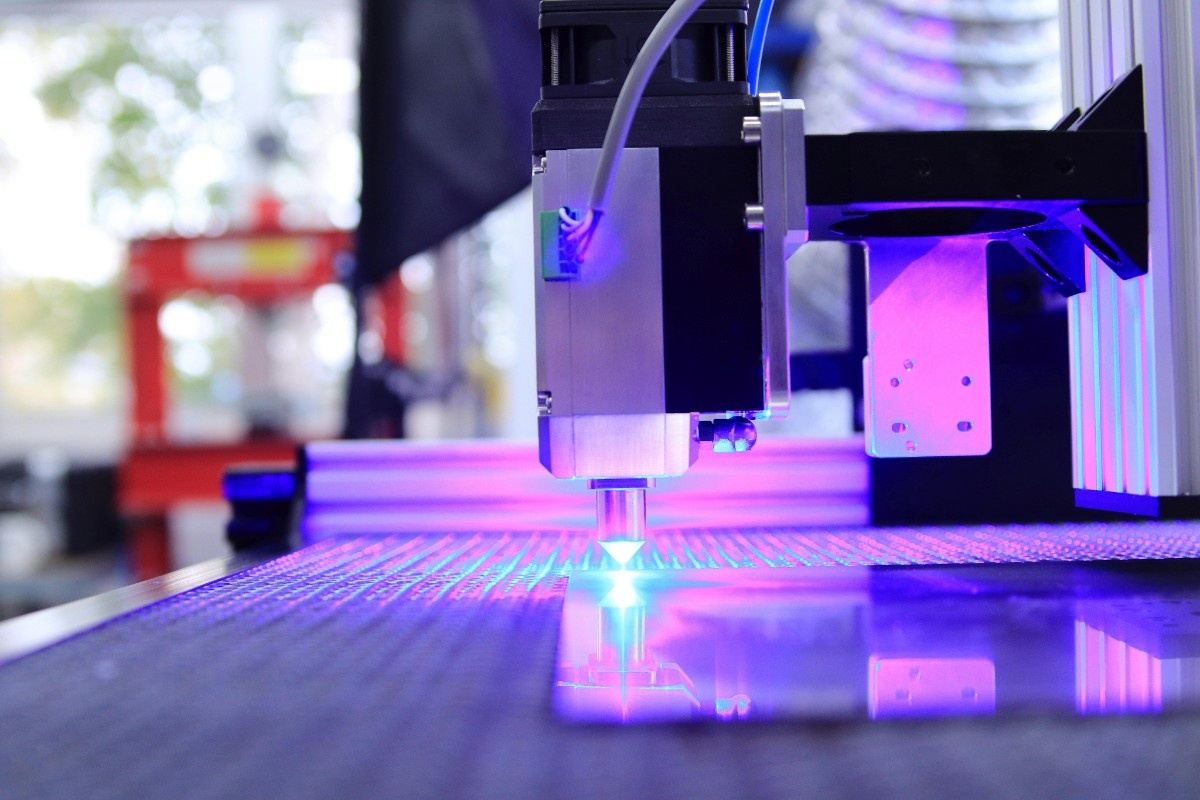

Complementing their machining capabilities, Zeometrix offers laser cutting and bending. This is crucial for clients in the electronics sector who need precision-machined internal components housed within custom-fabricated metal enclosures.

Industries Transformed by Zeometrix in Bangalore

The versatility of Zeometrix's CNC services allows them to serve a diverse range of high-stakes industries:

Aerospace and Defense

In Bangalore, the aerospace sector is the crown jewel. Components for satellites, missiles, and aircraft engines require materials like Titanium, Inconel, and Aluminum 7075. Zeometrix understands the stringent AS9100 standards and provides the necessary documentation and material traceability required for flight-certified parts.

Medical Devices

The medical industry demands biocompatibility and surface perfection. Zeometrix produces surgical instruments, orthopedic implants, and diagnostic equipment parts. Their clean machining processes ensure that there is no cross-contamination of materials, a vital requirement for healthcare applications.

Robotics and Automation

With Bangalore being a hub for robotics startups, Zeometrix provides the structural backbone for these machines. CNC machining allows for the creation of lightweight, high-strength articulated arms and sensor housings that 3D printing simply cannot match in terms of durability.

Semiconductor and Electronics

As India pushes for domestic semiconductor manufacturing, the demand for precision-machined vacuum chambers and wafer-handling parts has skyrocketed. Zeometrix’s ability to achieve micron-level precision makes them a key player in this emerging supply chain.

Material Excellence: What Can Be Machined?

The quality of a CNC-machined part is only as good as the material it’s made from. Zeometrix’s CNC machining services offer an extensive catalog of materials:

|

Category |

Specific Materials |

Common Use Cases |

|

Aluminum |

6061, 7075, 5082 |

Aerospace, Drones, Heat Sinks |

|

Stainless Steel |

304, 316, 17-4 PH |

Medical, Food Grade, Marine |

|

Specialty Alloys |

Titanium, Inconel, Brass |

Defense, Turbines, High-Wear parts |

|

Engineering Plastics |

PEEK, Delrin, Teflon, ABS |

Insulators, Bushings, Prototypes |

Zeometrix ensures that all materials are sourced from verified suppliers, providing Mill Test Reports (MTRs) to guarantee chemical and physical properties.

The Economics of CNC Machining in Bangalore

Why do global companies choose Bangalore—and specifically Zeometrix—over other global hubs like Shenzhen or Eastern Europe?

-

Cost-Efficiency: While Bangalore offers a significant labor cost advantage, it doesn't sacrifice quality. The "Cost-per-Precision" ratio in Bangalore is currently among the best in the world.

-

Intellectual Property (IP) Security: Bangalore has a robust legal framework for IP protection, making it a safer bet for companies developing proprietary technologies.

-

Communication: The high proficiency in English among Bangalore’s technical workforce minimizes the risk of manufacturing errors due to miscommunication.

Quality Control: The Zeometrix Standard

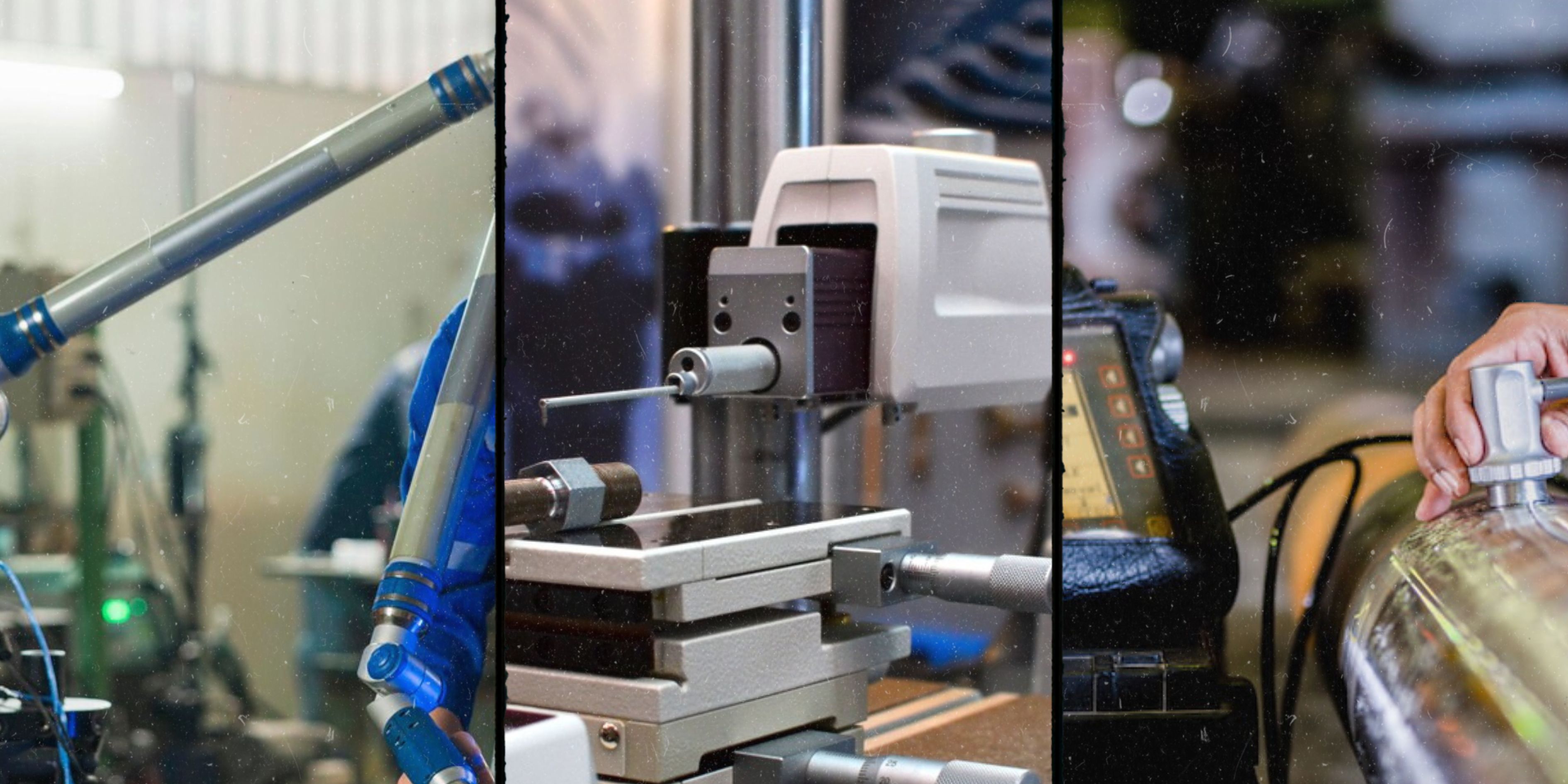

Precision machining is meaningless without verification. At Zeometrix, the quality control (QC) process is integrated into the production line, not just added at the end.

-

CMM Inspection: Coordinate Measuring Machines are used to verify the 3D coordinates of a part against the original CAD file.

-

Surface Roughness Testing: For parts requiring specific friction levels or aesthetic finishes.

-

Non-Destructive Testing (NDT): For critical aerospace components to ensure there are no internal fractures.

By providing detailed inspection reports with every shipment, Zeometrix builds a foundation of trust with its clients.

The Future of Manufacturing: Industry 4.0 in Bangalore

The future of CNC machining is not just about faster spindles; it’s about smarter data. Zeometrix is leading this shift by adopting:

-

Predictive Maintenance: Using AI to predict tool wear before it happens.

-

Digital Twins: Creating a virtual replica of the machining process to optimize tool paths and reduce cycle times.

-

Sustainable Machining: Implementing closed-loop coolant systems and recycling metal chips (swarf) to reduce the environmental footprint of manufacturing.

Conclusion

The evolution of CNC Machining in Bangalore has reached a tipping point where it is now a global leader in precision engineering. Companies like Zeometrix are at the forefront of this revolution, combining the traditional "grit" of Bangalore’s industrial heart with a "click-to-manufacture" digital efficiency.

Whether you are looking for a single complex prototype or a reliable partner for large-scale production, the Bangalore ecosystem—powered by Zeometrix—offers the technical expertise, material variety, and quality assurance necessary to compete on a global stage. In the world of precision, where every micron counts, Zeometrix is the partner that ensures your designs are never compromised.

Frequently Asked Questions (FAQs)

1. What is the standard accuracy/tolerance Zeometrix can achieve?

Zeometrix can consistently achieve tolerances as tight as $\pm 0.005$ mm for high-precision components. However, standard commercial tolerances are typically around $\pm 0.125$ mm, which is sufficient for most applications and more cost-effective.

2. Can Zeometrix help me if my CAD design is not optimized for machining?

Yes! One of the core values of Zeometrix is Design for Manufacturing (DFM) support. Their engineers review your files and suggest modifications that can reduce machining time, save material, and lower your overall costs without affecting the part's functionality.

3. What surface finishes does Zeometrix offer in Bangalore?

Zeometrix provides a full suite of finishing options, including Anodizing (Type II and III), Powder Coating, Bead Blasting, Electroplating, and Chemical Film (Chromate Conversion). This ensures your parts are ready for assembly the moment they arrive.

4. How does Zeometrix handle material certifications?

Every order can be requested with a Material Test Certificate (MTC). This document traces the material back to the original melt batch, ensuring it meets the specific chemical and physical standards required for your industry.

5. Does Zeometrix offer 5-axis CNC machining?

Yes, Zeometrix has access to advanced 5-axis CNC machining centers. This is ideal for complex geometries found in aerospace impellers, medical implants, and automotive engine components, as it allows for machining on all sides of a part with a single setup.