Engineering Precision at Every Step: Why Zeometrix Is a Trusted CNC Partner in Bangalore

Beyond its reputation as India’s tech capital, Bangalore has quietly evolved into a high-precision manufacturing hub. Industries spanning aerospace, automotive, medical devices, and electronics depend on CNC machining to meet exacting quality and performance standards.

At Zeometrix, we understand that in a competitive global market, "good enough" no longer cuts it. Whether you are a startup building a revolutionary medical prototype or an established OEM scaling up production, finding the right partner for CNC machining services in Bangalore is the difference between a successful product launch and a costly delay.

In this comprehensive guide, we will explore why Bangalore is the hub for precision engineering, how Zeometrix is redefining CNC standards, and what you should look for in a world-class machining partner.

Why Bangalore is the Heart of India’s Precision Engineering

The industrial landscape of Bangalore has evolved from a traditional manufacturing base into a high-tech ecosystem. Several factors make it the ideal location for CNC (Computer Numerical Control) services:

-

Industrial Hubs: Areas like Peenya, Jigani, Whitefield, and Hoskote host thousands of specialized small-scale and large-scale manufacturing units.

-

Skilled Talent Pool: With world-class institutions and decades of experience in public sector giants like HAL and ISRO, Bangalore possesses a workforce that understands the nuances of ±0.01mm tolerances.

-

Proximity to Innovation: The city’s status as an R&D hub means CNC service providers are constantly challenged to work with exotic materials and complex geometries.

Zeometrix: Your Trusted Partner for CNC Machining Services in Bangalore

At Zeometrix, we don’t just "cut metal." We provide end-to-end manufacturing solutions that bridge the gap between a CAD design and a high-performance physical component. Here is how we stand out in the crowded Bangalore market:

1. Comprehensive Machining Capabilities

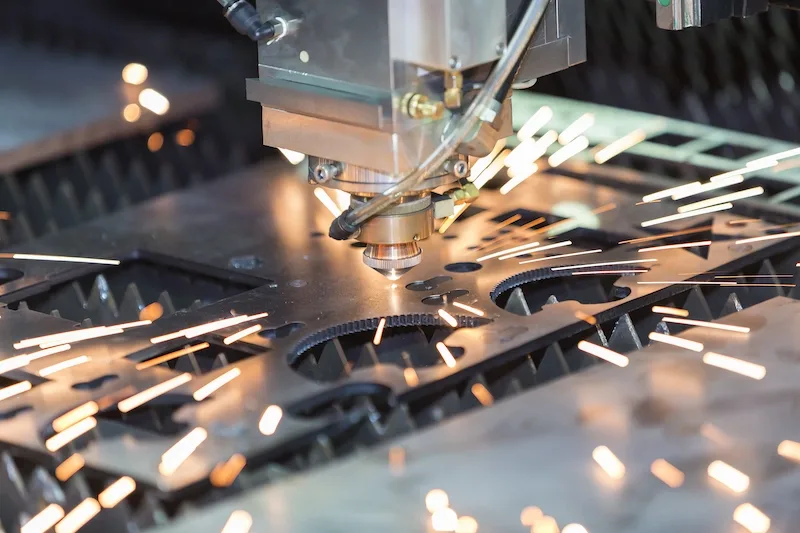

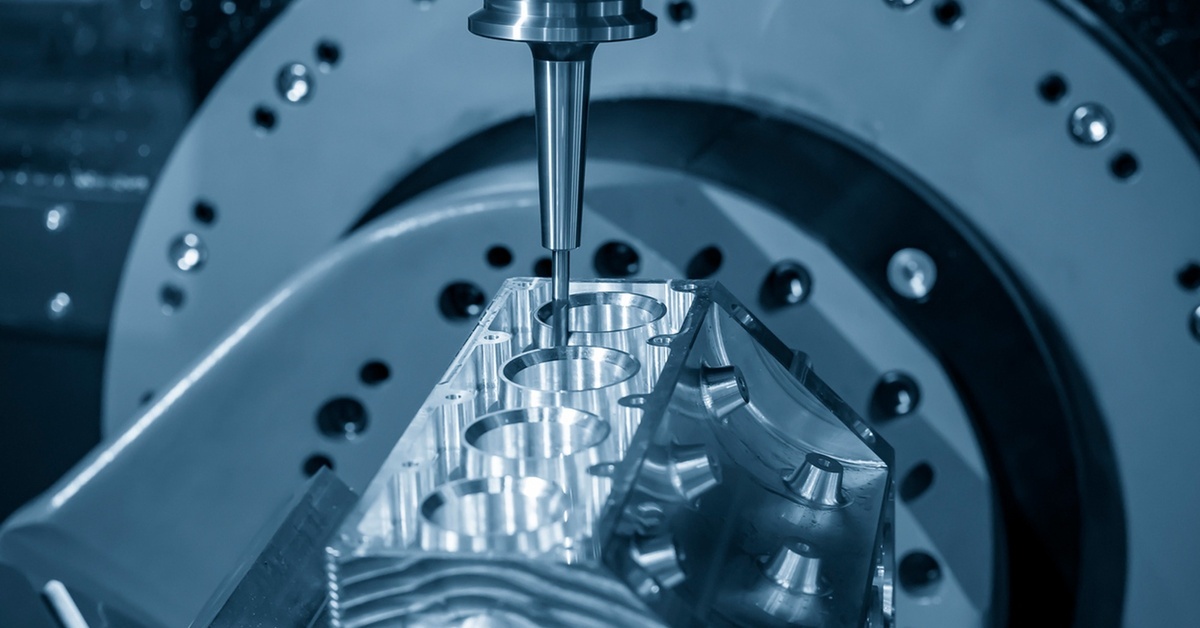

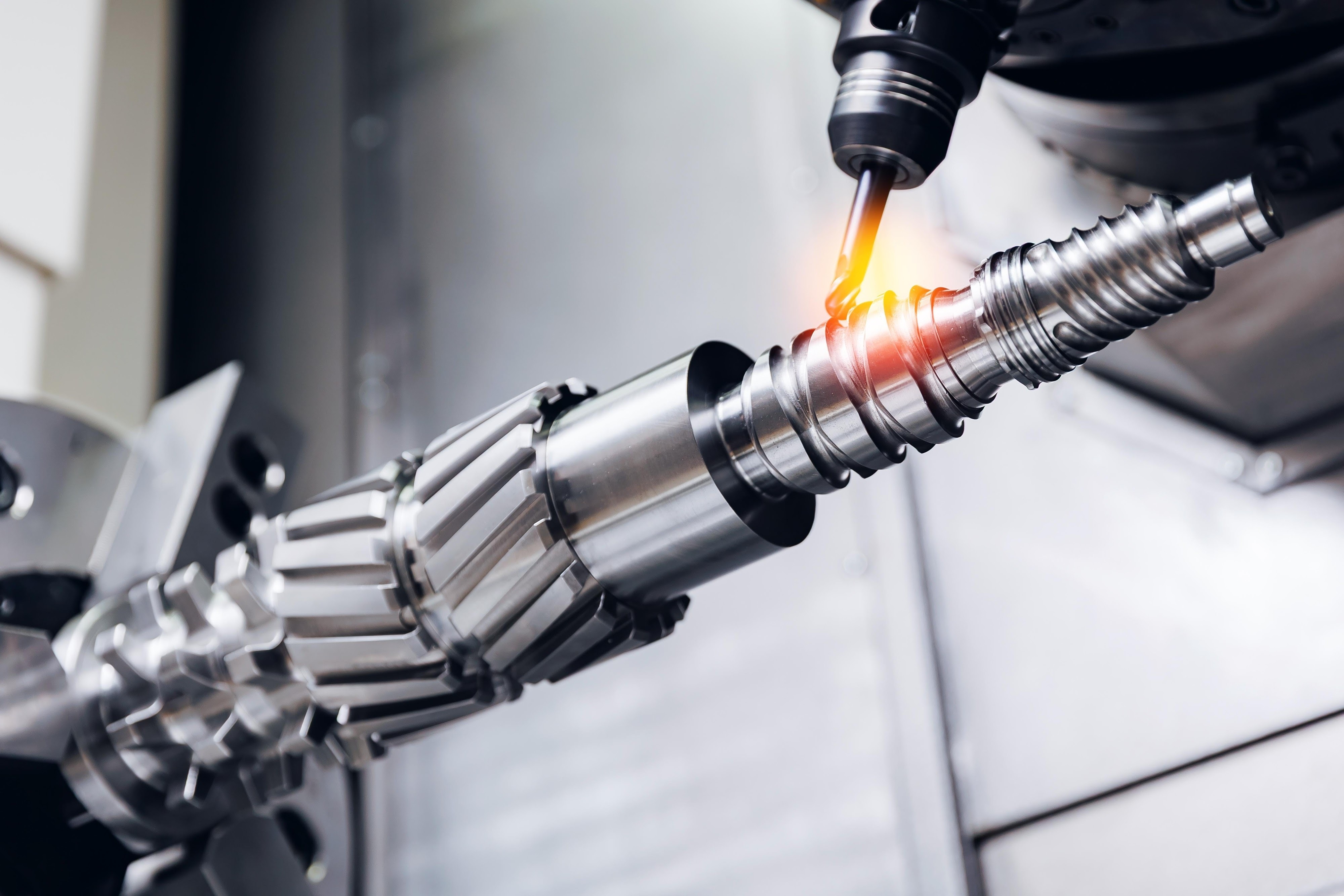

Our facility is equipped with state-of-the-art machinery capable of handling diverse manufacturing needs:

-

CNC Milling (3-Axis & 4-Axis): Ideal for complex prismatic parts with intricate surface details.

-

CNC Turning (Lathe): Perfect for high-precision cylindrical components like shafts, bushings, and flanges.

-

5-Axis Machining: For aerospace and medical components that require extreme geometry and single-setup precision.

-

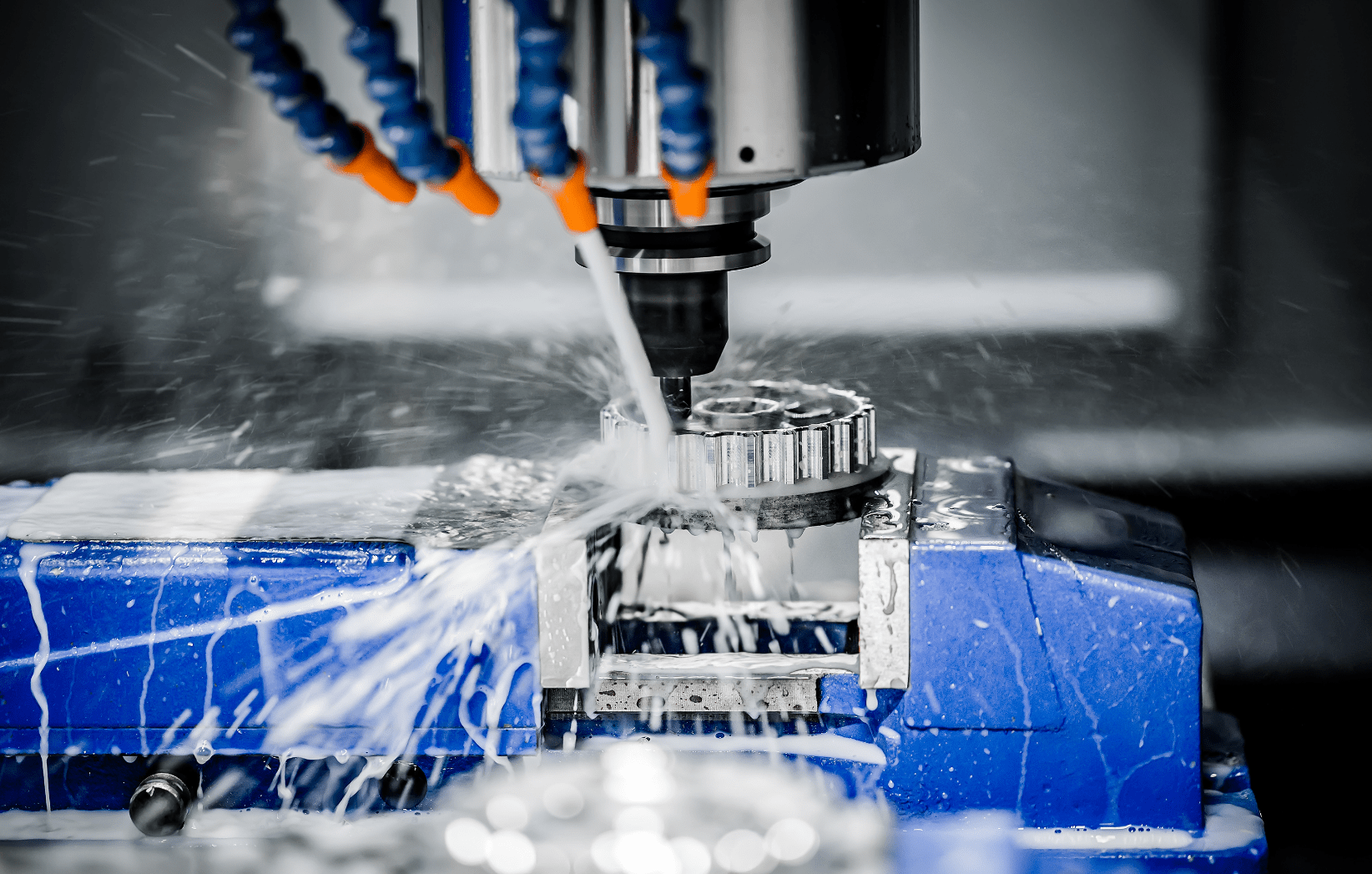

VMC (Vertical Machining Center): Optimized for high-speed production and superior surface finishes.

2. Material Versatility

The modern industry demands more than just mild steel. Zeometrix has extensive experience machining a wide array of materials:

-

Metals: Aluminum (6061-T6, 7075), Stainless Steel (304, 316, 17-4 PH), Titanium, Brass, Copper, and Alloy Steels.

-

Engineering Plastics: PEEK, POM (Delrin), Nylon, and PTFE.

3. Rapid Prototyping to Mass Production

We understand the product lifecycle. We offer low-volume prototyping (1–10 units) to help you test designs quickly, with the infrastructure to scale up to mass production (1000+ units) seamlessly.

The Zeometrix Advantage: Why Choose Us?

Searching for "CNC machining services in Bangalore" will give you hundreds of results. Why choose Zeometrix?

Quality Assurance & Inspection

Precision is meaningless without verification. At Zeometrix, every part undergoes rigorous inspection. We use calibrated CMM (Coordinate Measuring Machine) equipment and digital metrology tools to ensure that what we deliver matches your technical drawings exactly.

Speed and Efficiency

In the manufacturing world, time is money. By leveraging optimized toolpaths and advanced CAM (Computer-Aided Manufacturing) software, we reduce lead times without compromising quality. Most of our custom components are delivered within 5 to 10 business days.

Expert Engineering Support

We aren't just a job shop; we are your "thought partners." Our engineers often collaborate with clients to suggest DFM (Design for Manufacturing) improvements. These small tweaks can often reduce material waste and machining time, significantly lowering your per-part cost.

Key Industries We Serve in Bangalore

Our CNC machining services cater to the most demanding sectors in India and abroad:

|

Industry |

Common Components |

Key Requirement |

|

Aerospace & Defense |

Brackets, housings, engine mounts |

High strength-to-weight ratio |

|

Medical Devices |

Surgical instruments, implants, housings |

Biocompatibility & sterilization |

|

Electronics |

Heat sinks, enclosures, connectors |

Thermal management |

|

Automotive/EV |

Battery enclosures, motor mounts |

Durability and scalability |

|

Industrial Automation |

Jigs, fixtures, robot end-effectors |

Repeatability |

The 2025 Outlook: Future Trends in CNC Machining

As we move into 2025, the CNC industry in Bangalore is witnessing a massive shift. Zeometrix is at the forefront of these technological advancements:

1. AI-Driven Process Optimization

We are integrating AI modules to predict tool wear and optimize cutting speeds. This reduces downtime and ensures a "right first time" approach to complex jobs.

2. Hybrid Manufacturing

The combination of 3D printing (additive) and CNC machining (subtractive) is becoming a standard. We use 3D printing to create "near-net-shape" blanks, which are then precision-machined on our CNC centers to achieve final tolerances. This saves up to 30% in material costs.

3. Sustainability and Green Machining

With global eyes on carbon footprints, Zeometrix is adopting eco-friendly coolants and high-efficiency motors to reduce energy consumption. We also ensure that 100% of our metal scrap is recycled through certified partners.

How to Get Started with Your CNC Project

Transitioning from a design to a finished part is simple with Zeometrix. Here is our streamlined process:

-

Request a Quote: Upload your CAD files (STEP, IGES, or SolidWorks) via our portal or email.

-

Design Review: Our engineers review your file for manufacturability and provide a cost estimate.

-

Machining: Once approved, your project is scheduled on the optimal machine (Milling or Turning).

-

Quality Check: Parts are cleaned, deburred, and inspected against your tolerances.

-

Delivery: Securely packaged components are delivered to your doorstep in Bangalore or shipped globally.

Choosing the Best CNC Machining Service in Bangalore: A Checklist

If you are evaluating multiple vendors, keep this checklist handy:

-

Do they offer 5-axis capabilities? Many complex parts cannot be made on 3-axis machines.

-

What is their tolerance limit? Look for providers who can hit ±0.01mm or better.

-

Is there a secondary process service? Ask if they provide anodizing, powder coating, or heat treatment.

-

Are they ISO certified? Certification ensures a standardized quality management system.

-

Can they handle diverse materials? A shop that only does mild steel won't help if your design shifts to Titanium or PEEK.

Conclusion

The demand for high-quality CNC machining services in Bangalore continues to grow as India cements its position as a global manufacturing hub. At Zeometrix, we are proud to be part of this journey, combining the city's legacy of engineering excellence with modern, data-driven manufacturing techniques.

Whether you are looking for a one-off prototype or a reliable long-term production partner, Zeometrix has the technology, the talent, and the commitment to bring your vision to life with surgical precision.

Frequently Asked Questions (FAQ)

1. What is the typical lead time for CNC machining projects in Bangalore? At Zeometrix, lead times depend on the complexity and volume of the order. For rapid prototyping, we typically deliver parts within 3 to 5 business days. For larger production runs or parts requiring specialized post-processing (like anodizing or heat treatment), the average turnaround is 1 to 2 weeks. Being based in Bangalore allows us to offer faster local logistics compared to out-of-state vendors.

2. What levels of precision and tolerance can Zeometrix achieve? We specialize in high-precision engineering. Our standard machining tolerance is ±0.05mm to ±0.1mm. However, for mission-critical industries like aerospace and medical devices, we can achieve tight tolerances of up to ±0.01mm or even 1-5 microns depending on the part geometry and material stability.

3. Which materials do you commonly work with? As a versatile service provider in Bangalore, we work with a wide range of materials:

-

Metals: Aluminum (6061, 7075), Stainless Steel (304, 316), Titanium (Grade 5), Brass, Copper, and Alloy Steels.

-

Plastics: PEEK, POM (Delrin), Nylon, Polycarbonate, and ABS.

-

Specialty: Tool steels and exotic alloys for industrial tooling.

4. Do you have a Minimum Order Quantity (MOQ)? No, Zeometrix is committed to supporting both innovators and large-scale manufacturers. We have no minimum order quantity. Whether you need a single custom prototype to test a design or 10,000 units for a commercial launch, we provide the same level of precision and quality control.

5. How much do CNC machining services cost per hour in Bangalore? The cost is influenced by the machine type (3-axis vs. 5-axis), material choice, and setup time. In the Bangalore market, 3-axis milling typically starts around ₹450 to ₹800 per hour, while advanced 5-axis machining or specialized VMC work can be higher. At Zeometrix, we provide a transparent, line-item quote based on your CAD file to ensure you get the most cost-effective manufacturing path.