Trusted by 10,000+ Engineers: Unmatched CNC Machining in Bangalore Quality and Capacity

In the world of high-stakes engineering and manufacturing, there is no substitute for precision, reliability, and sheer production capacity. Bangalore, the heart of India's technological and industrial growth, demands the best, especially when it comes to the backbone of modern production: CNC Machining.

When a firm earns the trust of over 10,000 engineers and procurement leaders, it's a testament not just to a good service, but to an unwavering commitment to excellence, scale, and technological superiority. This is the story of how Zeometrix has established itself as the single-stop solution for high-quality, high-volume, and high-precision CNC Machining in Bangalore. We don't just cut metal; we forge trust.

The Foundation of Trust: Unrivalled Quality and Accuracy

For any engineer, the true measure of a manufacturing partner is their ability to hit the numbers—consistently. At Zeometrix, our quality promise is built on three non-negotiable pillars: ISO Certification, Micro-Precision, and Continuous Improvement.

The ISO 9001:2015 Quality Guarantee

In a complex supply chain, you cannot afford to guess about quality. Our ISO 9001:2015 certified quality management system is not just a badge; it is the framework that guarantees exceptional craftsmanship and process reliability.

- Consistency You Can Count On: ISO certification mandates documented, standardized processes. This means whether you order one prototype or a batch of ten thousand parts, the outcome is consistent, repeatable, and traceable.

- Reduced Risk: The standard requires a risk-based approach to manufacturing. This proactive measure minimizes the potential for defects, costly rework, and production delays, offering peace of mind to procurement leaders.

- Full Traceability: Every machined part comes with detailed documentation, from material certificates to final inspection reports. This level of transparency is crucial for regulated industries like aerospace and automotive, which have a major presence in the Bangalore industrial ecosystem.

Reaching the Limits of Precision: Up to 20 Microns

Precision is where engineering turns into art. While many shops aim for standard tolerances, Zeometrix is equipped to achieve tight tolerances of up to 20 microns.

To put that in perspective: 20 microns is less than half the diameter of a human hair. Achieving this level of precision repeatedly speaks directly to the quality of our machinery, the skill of our machinists, and the sophistication of our programming.

This micro-precision is vital for complex, high-performance parts used in sectors driving Bangalore's economy, from advanced medical devices to aerospace components and high-end automotive systems.

The Power of Scale: Unmatched Production Capacity

Quality is meaningless without the capacity to deliver on time, especially in a dynamic market like Bangalore. Our CNC machining services, combined with our commitment to scale, differentiate us and allow us to serve a diverse client base—from nimble startups requiring rapid prototypes to multinational corporations demanding massive production runs.

Over 2,000 Machines at Your Disposal

Our network capacity is arguably our most powerful asset. With access to over 2,000 machines, Zeometrix eliminates the traditional supply chain bottleneck. This enormous manufacturing network provides:

- Immediate Production Allocation: We can instantly allocate your job to the right facility and machine, drastically reducing lead times and ensuring quicker turnarounds.

- Volume Flexibility: Whether your requirement is small-batch prototyping or high-volume end-use production, our scale means we can absorb demand fluctuations without compromising delivery schedules.

- Redundancy and Reliability: This extensive network acts as an ultimate backup, ensuring that even in the unlikely event of a single machine or facility issue, your production remains uninterrupted.

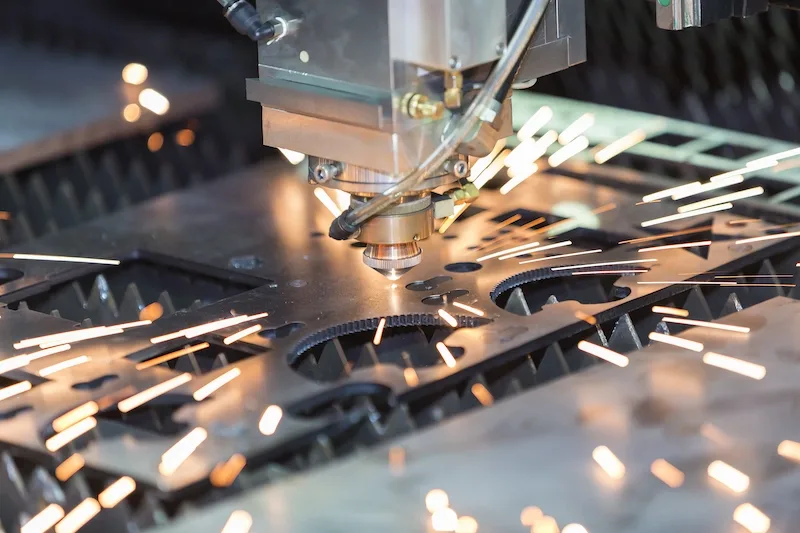

Specialized Machining Capabilities for Every Need

Our capacity isn't just about quantity; it's about technological breadth. Our service capabilities span the full spectrum of modern CNC technologies:

|

CNC Service |

Key Application & Benefit |

|

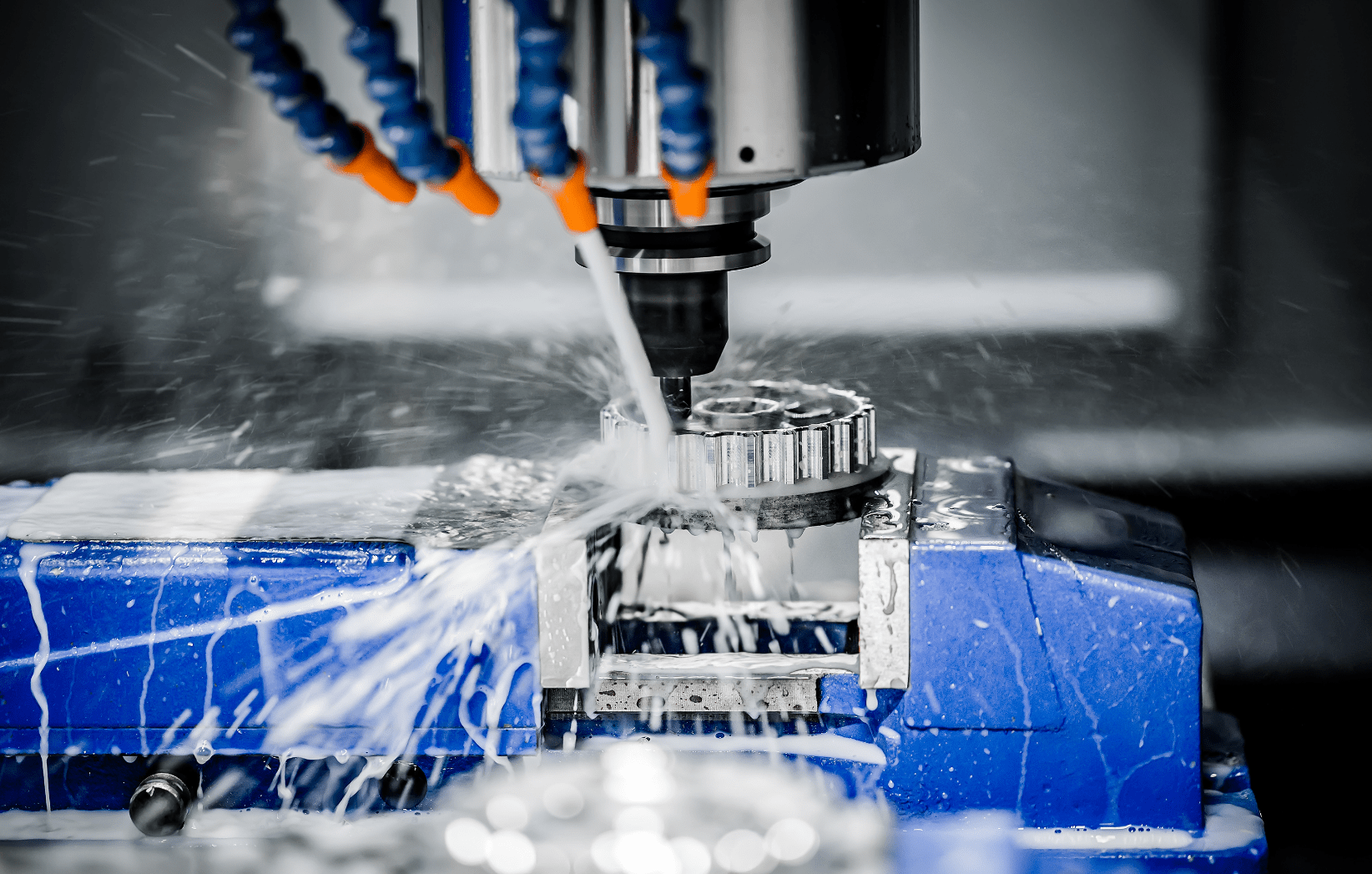

CNC Milling |

For accurate shaping of flat, angular, and complex contours (e.g., enclosures, brackets, custom parts). |

|

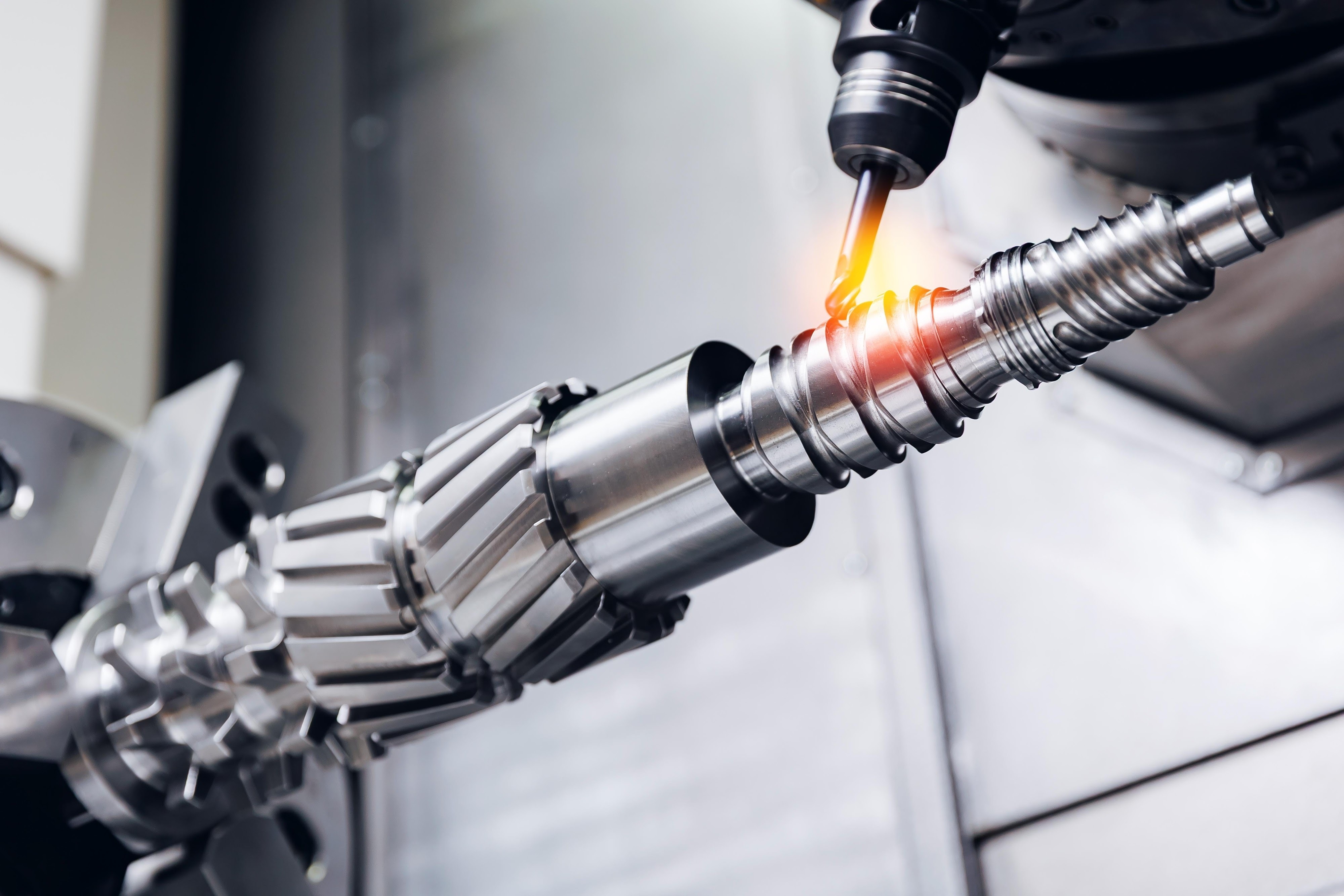

CNC Turning |

For creating high-accuracy, smooth-finish cylindrical components (e.g., shafts, bushings, pins). |

|

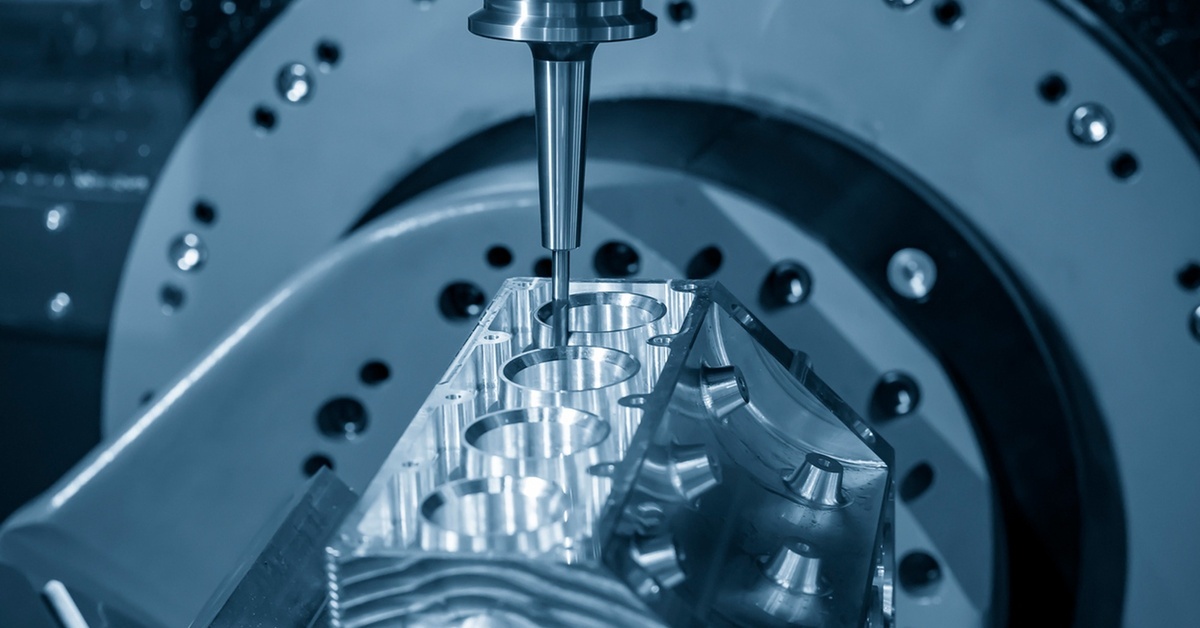

5-Axis Machining |

Essential for complex geometries, turbine blades, and parts requiring a flawless surface finish in a single setup, minimizing error. |

|

CNC Routing |

Ideal for large-format, flat-sheet materials with speed and efficiency. |

|

Electrical Discharge Machining (EDM) |

Used for securing quotes on EDM parts, this process is crucial for working with extremely hard materials and achieving intricate shapes with excellent surface quality. |

The adoption of 5-Axis Machining is particularly critical in the Bangalore industrial zone, which is a major hub for aerospace and automotive innovation. This advanced technology allows us to create complex, lightweight, and intricate designs that are simply impossible on conventional 3-axis machines, giving our clients a distinct competitive edge.

Speed and Transparency: The Zeometrix Workflow Advantage

The digital age demands speed and clarity. We've streamlined the entire manufacturing lifecycle to ensure that the process from design upload to finished part is as fast and transparent as possible.

Instantaneous Quoting

We understand that project planning begins with a swift and accurate cost assessment. That's why we offer Instantaneous Quoting.

- Submit Your Files: Upload your 3D files (SLDPRT, STEP, STP, STL, DXF, DWG, IGES, PDF).

- Get a Quick Quote: Our sophisticated system and dedicated professionals process your submission to provide you with a quote instantaneously.

This efficient process allows engineers to iterate designs, adjust materials, and secure budget approval faster than ever before.

Explicit Pricing Structure

Unforeseen costs are the bane of any procurement process. Our explicit pricing structure ensures that there are no hindrances in your project planning. You get clear, upfront costs, allowing for effective budget management and execution of your entire project.

Engineering the Future: Applications and Innovation

The true impact of our CNC Machining in Bangalore service is seen in the applications we enable across diverse industries. We support innovation at every stage of the product lifecycle:

1. Rapid Prototyping

This method uses our computerized equipment to produce parts instantaneously. It is invaluable for design validation, form-and-fit testing, and accelerating the time-to-market for new products, cost-effectively creating complex geometries with high accuracy.

2. Rapid Tooling

For projects that require custom molds and tools, our fast CNC machining process reduces the lead time taken for development. We produce highly precise tools using advanced technologies, saving both cost and time in the overall manufacturing cycle.

3. End-Use Production

Backed by our ISO certification and certifiable material choices, our high-precision and improved performance finishing makes us the best choice for developing high-stakes end-use parts in multiple industries such as:

- Aerospace: Precision components for flight control and engine systems.

- Automotive: High-performance engine blocks, turbochargers, and complex transmission parts.

- Medical: Implants, surgical tools, and precision housing for diagnostic equipment.

Beyond the Machine: Partnership and Commitment

Our success is measured by the success of the 10,000+ engineers and procurement leaders who have placed their faith in us. Our commitment extends far beyond the cut of the tool.

Customer-Centric Approach

Every element of our operation—from our secure file upload system to our dedicated team of professionals—is built to put the client first. We ensure that every submission is treated as secure and confidential, and our team is always ready to process your query and supply you with the best possible service.

The Bangalore Ecosystem Advantage

Bangalore is a magnet for high-tech manufacturing, and as a key player in this ecosystem, Zeometrix provides a localized, responsive, and globally competitive manufacturing solution right at the heart of industrial innovation.

Zeometrix is your one-stop for all manufacturing services. Get instantaneous quotes, achieve the tightest tolerances, and leverage a massive network capacity to turn your vision into a reality.

Ready to partner with the most trusted name in CNC Machining in Bangalore?

Frequently Asked Questions (FAQs)

1. What level of precision can Zeometrix achieve for CNC machined parts?

Zeometrix is equipped to achieve tight tolerances of up to 20 microns. This micro-precision ensures parts meet the rigorous standards required for industries like aerospace, automotive, and medical devices.

2. How does Zeometrix ensure the quality of its CNC machining services?

Quality is guaranteed through an ISO 9001:2015 certified quality management system. This certification ensures standardized, repeatable, and traceable manufacturing processes, guaranteeing exceptional and consistent craftsmanship.

3. How quickly can I get a quote for my CNC machining project?

Zeometrix offers Instantaneous Quoting. By submitting your 3D files (like SLDPRT, STEP, STP, STL, etc.), you can receive a quick and accurate quote from their dedicated professionals, accelerating your project planning.

4. What is the production capacity and machine variety available through Zeometrix?

Zeometrix provides unmatched capacity with access to over 2,000 machines across its network. This allows them to handle small-batch prototyping to high-volume end-use production and specialize in services like CNC Milling, CNC Turning, 5-Axis Machining, and EDM.

5. What types of projects can utilize Zeometrix's CNC Machining services?

Zeometrix supports the entire product lifecycle, including Rapid Prototyping (for design validation), Rapid Tooling (for fast mold creation), and End-Use Production (for high-performance parts in aerospace, automotive, medical, and other industries).