Smart Factories, Smarter Machining: The Evolution of CNC Manufacturing in Bangalore

In the rapidly evolving landscape of global manufacturing, Bangalore has transitioned from being the "Silicon Valley of India" to a formidable "Global Manufacturing Hub." As industries like aerospace, electric vehicles (EVs), and medical technology demand higher levels of precision, the reliance on CNC machining services in Bangalore has reached an all-time high.

At the forefront of this industrial shift is Zeometrix, a company dedicated to bridging the gap between complex engineering designs and tangible, high-performance components. In this 1,500-word deep dive, we explore why precision machining is the heartbeat of Bangalore’s industry and how Zeometrix is leading the way.

1. The Evolution of CNC Machining in Bangalore’s Ecosystem

Bangalore’s industrial history began with public sector giants like HAL and BEL, but today, it is a mosaic of MSMEs and tech-driven startups. The city’s ecosystem is unique because it demands a "high-mix, low-volume" production model—where complexity is high, and the room for error is zero.

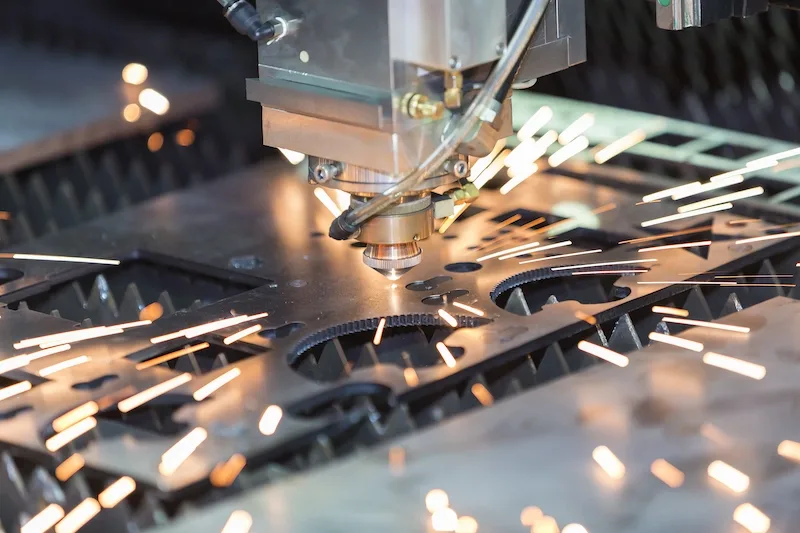

The Shift from Manual to Digital

A decade ago, many workshops in Peenya and Bommasandra relied on manual milling and turning. However, as global companies began outsourcing to India, the need for repeatability and micron-level accuracy became paramount. Computer Numerical Control (CNC) machining solved this by automating the movement of factory tools and machinery using pre-programmed software.

Zeometrix entered this space to modernize the experience. By integrating advanced software with heavy-duty hardware, we provide a digital thread that follows a part from the initial CAD upload to the final quality inspection.

2. Why Zeometrix is the Preferred Choice for CNC Machining Services in Bangalore

Choosing a machining partner isn't just about finding someone with a mill; it’s about finding a partner who understands the physics of materials and the economics of production.

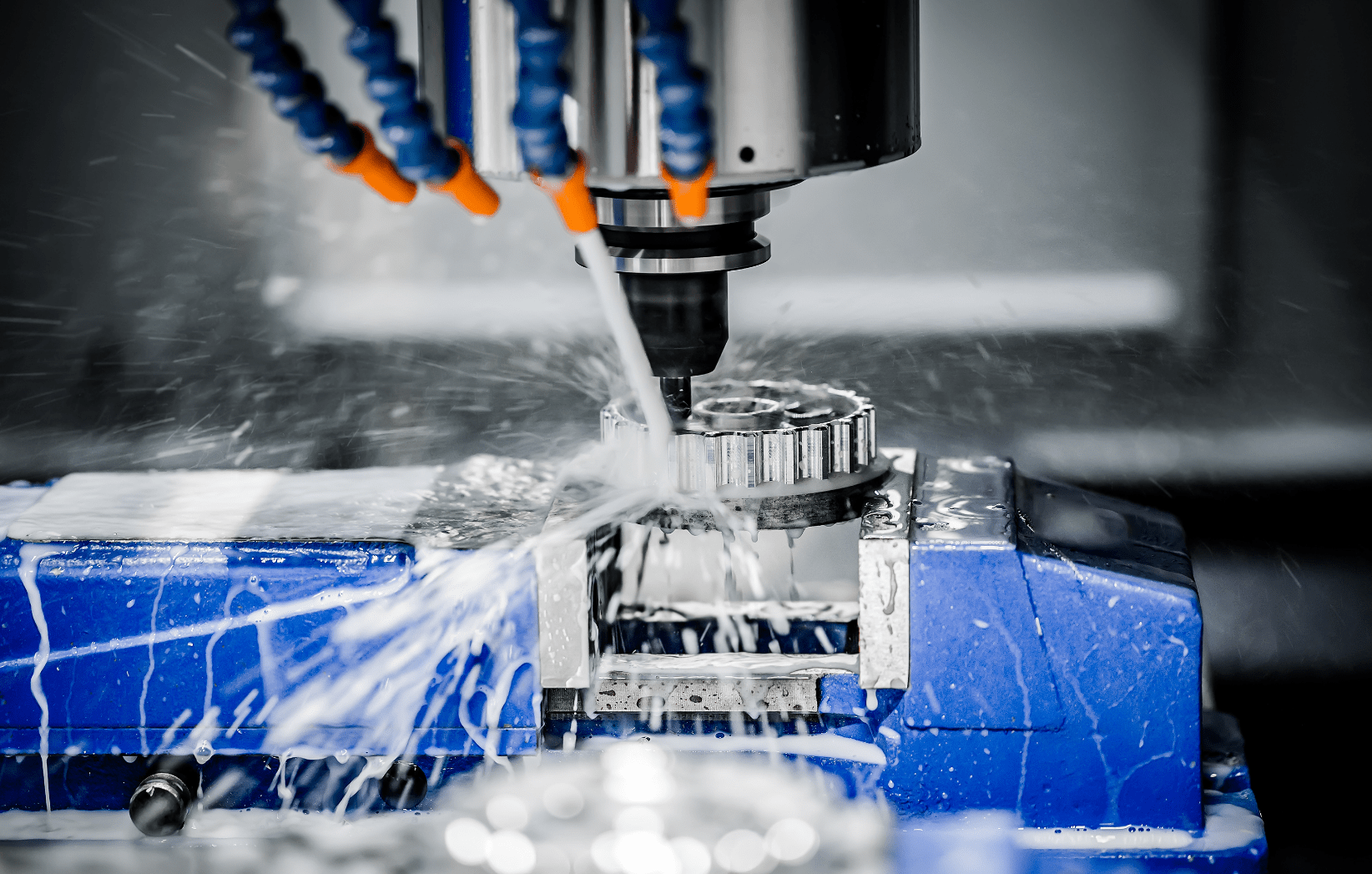

A. Advanced Machinery and Technology

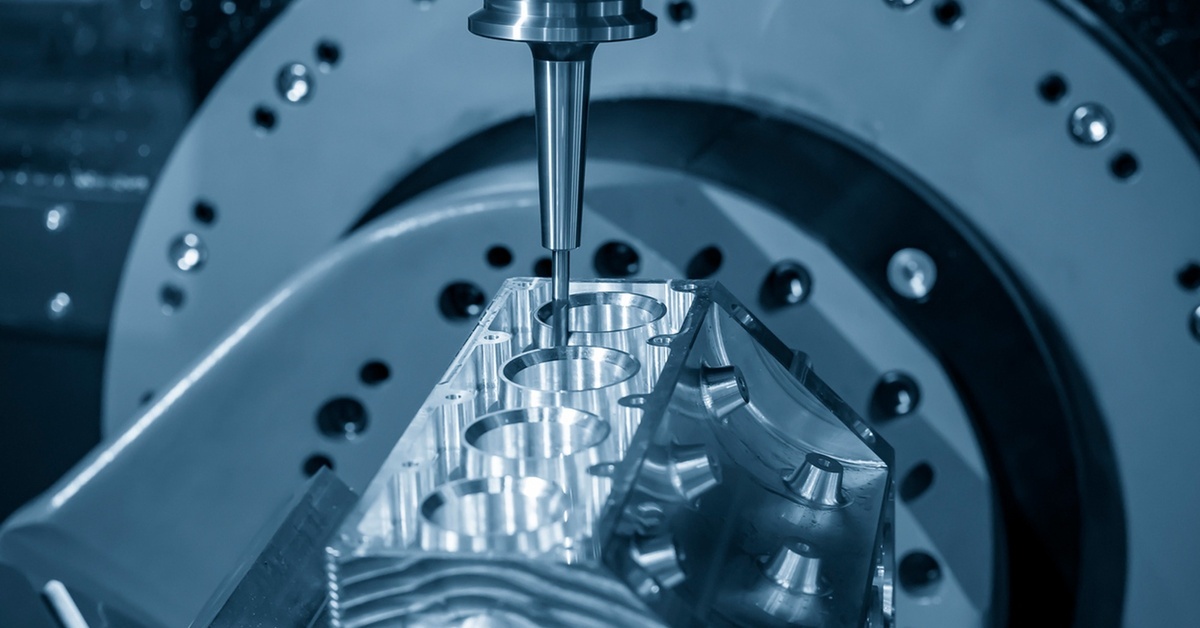

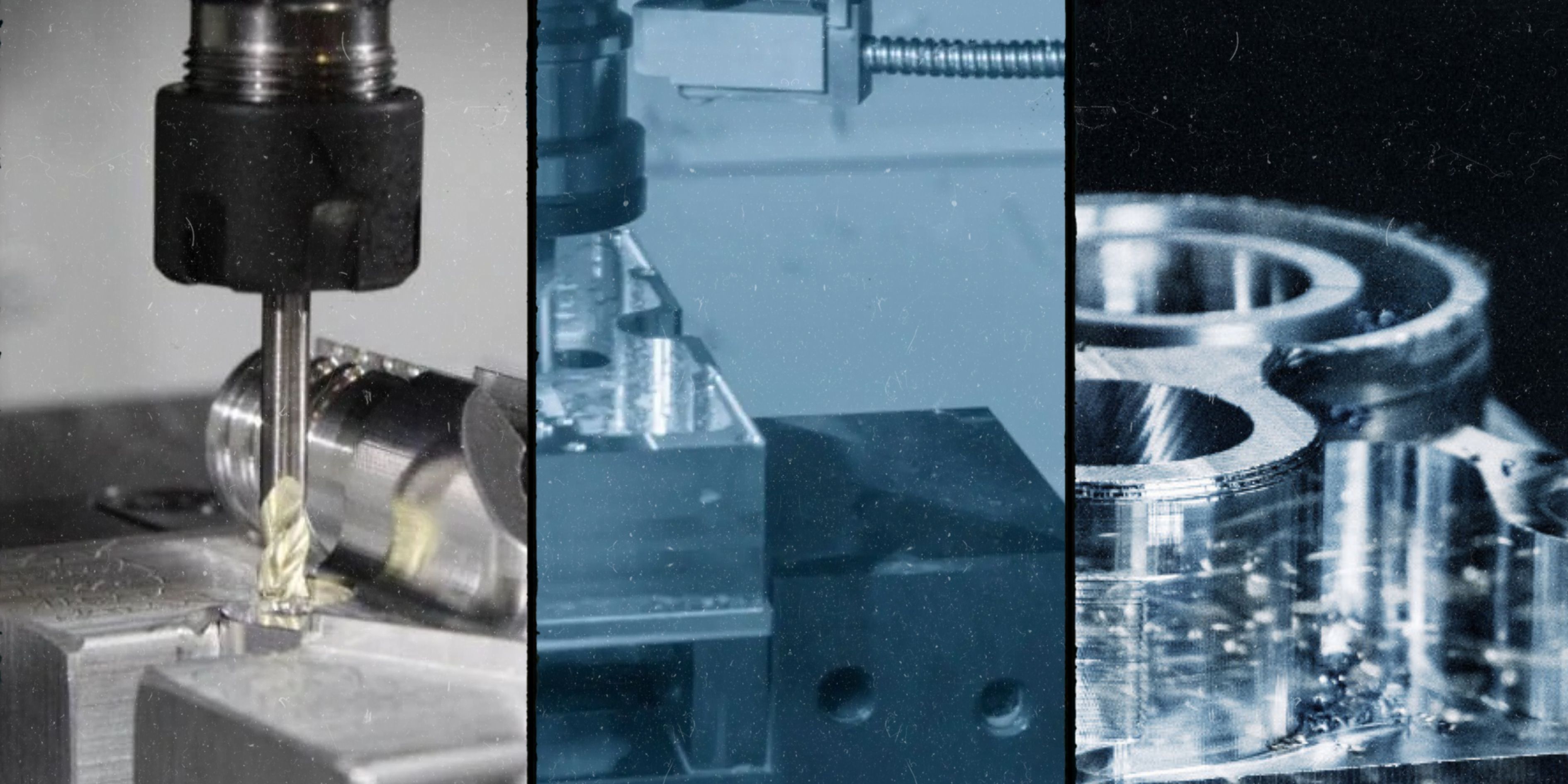

Zeometrix utilizes state-of-the-art 3-axis, 4-axis, and 5-axis CNC machines.

-

3-Axis Machining: Best for simpler parts that require flat surfaces or basic pockets.

-

4-Axis Machining: Adds a degree of rotation, allowing for features on the side of a part without multiple setups.

-

5-Axis Machining: This is where Zeometrix truly shines. By moving the cutting tool across five different axes simultaneously, we can create complex organic shapes, undercuts, and intricate geometries required for aerospace turbines or medical implants.

B. The "Design for Manufacturing" (DfM) Philosophy

One of the biggest hurdles in manufacturing is a design that looks great on screen but is impossible (or too expensive) to machine. Our engineers at Zeometrix provide detailed DfM feedback. We look for:

-

Deep Pockets: Tools can vibrate (chatter) if they have to reach too deep, ruining the finish.

-

Internal Radii: CNC tools are round; they cannot cut a perfectly square internal corner. We suggest radii adjustments that maintain strength while reducing cost.

-

Wall Thickness: We advise on the minimum thickness required to prevent warping during the machining process.

3. Deep Dive into Materials: From Aerospace Alloys to Engineering Plastics

A significant part of our CNC machining services in Bangalore involves consulting on material selection. The local climate (moderate but humid) and the end-use environment dictate what we use.

Metals

-

Aluminum (6061, 7075): The workhorse of the industry. 6061 is highly weldable and versatile, while 7075 is the "aerospace grade" with a strength-to-weight ratio comparable to steel.

-

Stainless Steel (304, 316, 17-4 PH): Essential for medical and food-processing equipment in Bangalore. 316 is particularly resistant to corrosion.

-

Titanium (Grade 5): Known for its incredible strength and biocompatibility, though it is notoriously difficult to machine. Zeometrix uses specialized cooling and tooling techniques to master Titanium.

-

Brass and Copper: Primarily used for electrical components and heat sinks due to high conductivity.

Plastics

Not all CNC machining is about sparks and metal. Engineering plastics are vital for insulation and weight reduction.

-

PEEK: A high-performance thermoplastic used in space-tech.

-

Delrin (POM): Highly machinable with great dimensional stability, perfect for gears.

-

Nylon and Teflon: Used for bushings and seals where low friction is required.

4. Industry-Specific Applications in the Bangalore Market

Aerospace and Defense

Bangalore is the headquarters of ISRO and several private space agencies. Zeometrix supports these missions by manufacturing:

-

Satellite Housings: Requiring high EMI shielding.

-

Manifolds: For fluid control in rocket engines.

-

Structural Brackets: Optimized for weight using generative design.

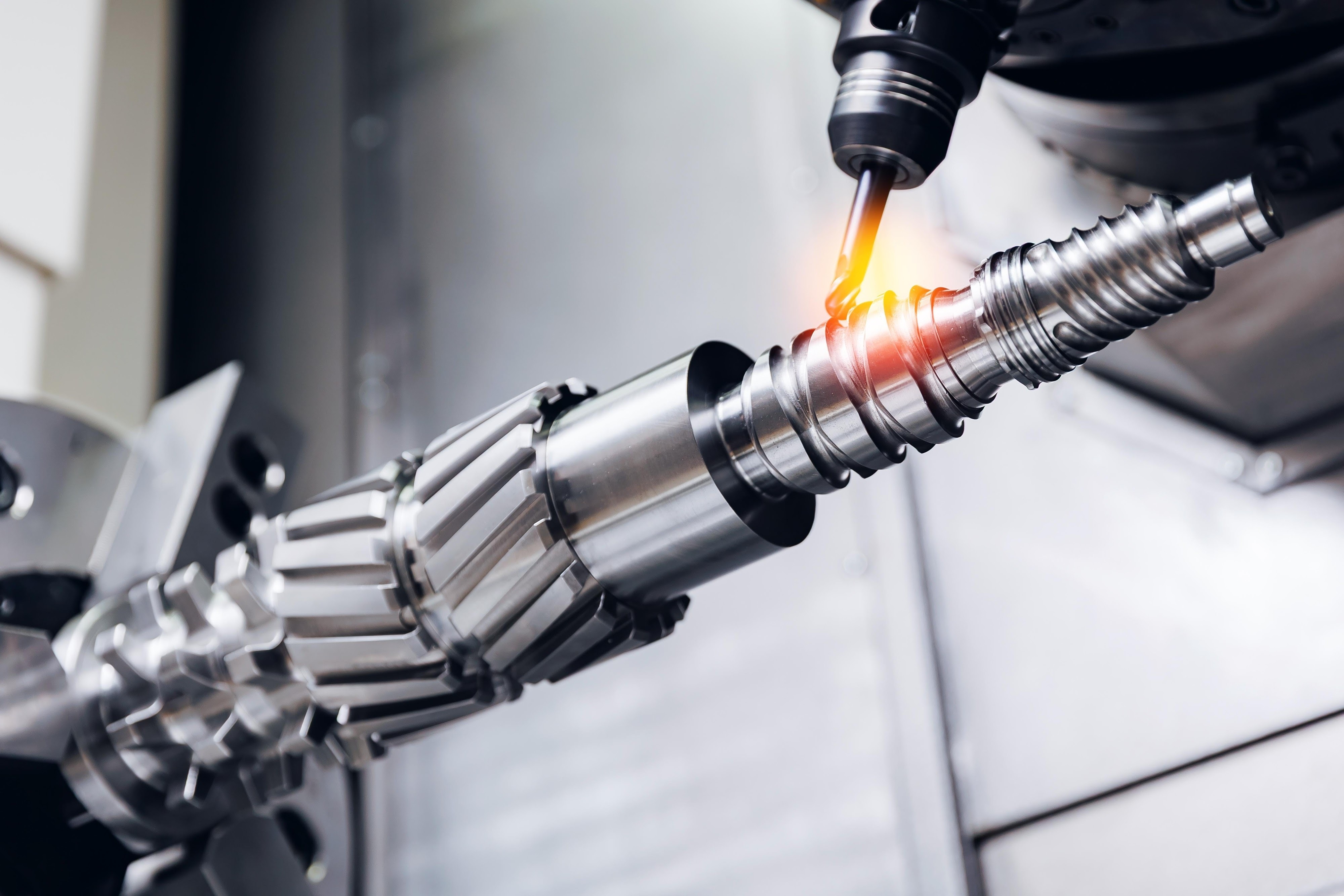

The Electric Vehicle (EV) Revolution

With companies like Ather Energy and Ola Electric based here, the demand for custom EV parts is booming. We provide:

-

Battery Cold Plates: Intricate channels for liquid cooling.

-

Motor Cases: Precision-turned housings for high-RPM motors.

-

Inverter Enclosures: Custom-milled aluminum boxes for power electronics.

Medical Technology

Precision in medical devices is non-negotiable. We produce:

-

Surgical Robotic Arms: Requiring zero-backlash components.

-

Orthopedic Drills: Custom-tooled for ergonomic and functional use.

-

Diagnostic Equipment Frames: Ensuring that sensitive optical sensors are perfectly aligned.

5. The Zeometrix Quality Assurance Process

Quality is not an afterthought at Zeometrix; it is baked into the process. As a trusted provider of CNC manufacturing near me, our facility in Bangalore follows rigorous standards to ensure every part matches the customer's blueprint.

Metrology and Inspection

-

CMM Inspection: Our Coordinate Measuring Machine measures the physical coordinates of a part to ensure it matches the 3D model.

-

Surface Roughness Testing: For parts that require specific friction levels, we measure the $R_a$ (roughness average) to ensure it meets specifications.

-

Material Traceability: We provide Mill Test Reports (MTR) so you know exactly where your metal came from.

Post-Processing Services

A machined part often needs a "final touch." We offer:

-

Anodizing: Hard coat or decorative.

-

Bead Blasting: To remove tool marks.

-

Electroless Nickel Plating: For wear resistance and hardness.

-

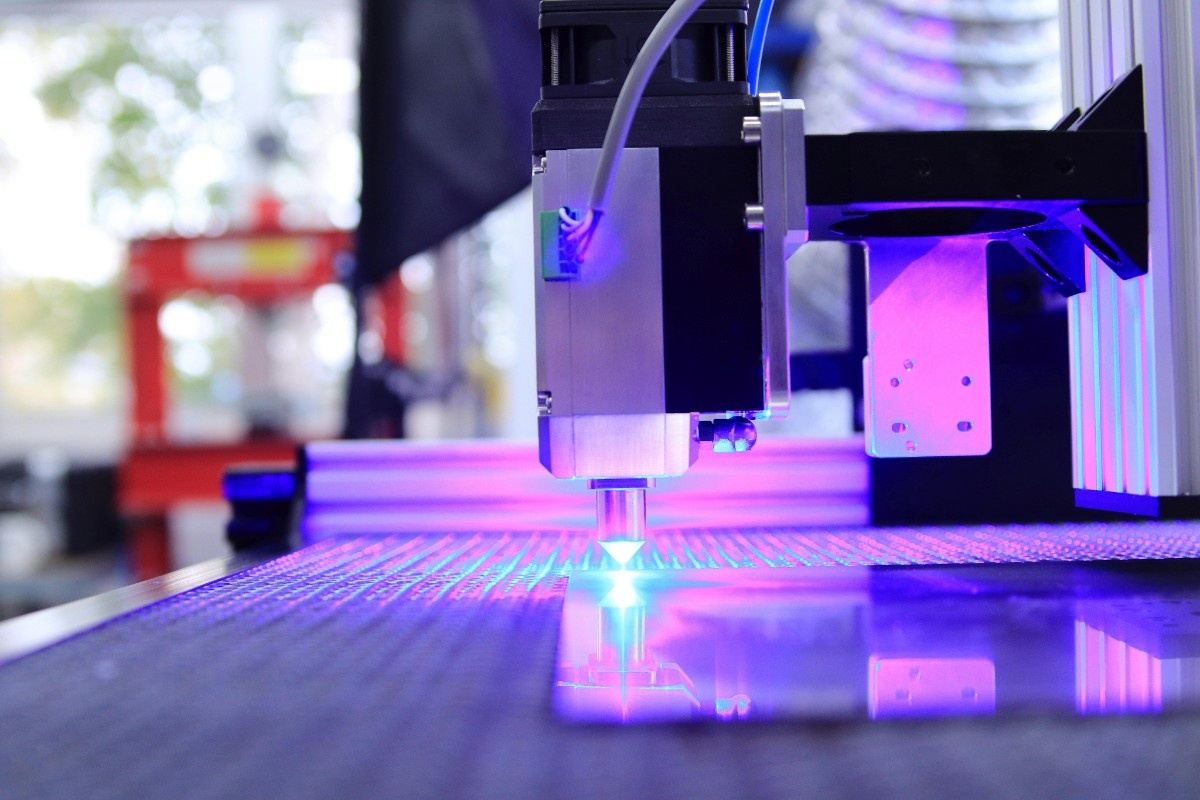

Laser Etching: For part numbering and branding.

6. Navigating the Challenges of Manufacturing in India

While there are many providers of CNC machining services in Bangalore, the challenges are real: power fluctuations, supply chain delays, and talent retention.

Zeometrix overcomes these through:

-

Infrastructure Investment: Backup power systems to ensure 24/7 machine uptime.

-

Localized Supply Chain: We maintain strong relationships with local raw material suppliers to hedge against global shipping delays.

-

Continuous Training: Our machinists undergo regular training on the latest CAM (Computer-Aided Manufacturing) software updates.

7. The Future of CNC: AI, Automation, and Zeometrix

As we look toward the late 2020s, the "Smart Factory" is becoming a reality. Zeometrix is investing in:

-

Automated Tool Changers: Reducing human intervention and increasing speed.

-

AI-Optimized Toolpaths: Algorithms that calculate the most efficient way to remove material, saving the customer money on machine time.

-

Cloud-Based Tracking: Allowing our customers in Bangalore and abroad to track their order status in real-time.

8. Conclusion

Precision is the language of progress. As Bangalore continues to lead India’s technological charge, the need for reliable, high-quality CNC machining services will only grow. Zeometrix is more than just a service provider; we are a strategic partner for engineers and innovators. By combining the best of Bangalore's technical talent with world-class machinery and a transparent digital workflow, we ensure that your most ambitious designs are realized with perfection.

Whether you are looking for a single prototype or a long-term production partner, Zeometrix has the capacity, the expertise, and the passion to deliver.

Frequently Asked Questions (FAQ)

1. What is the minimum order quantity (MOQ) at Zeometrix?

We have no MOQ. We support everything from a "Quantity: 1" prototype for R&D to full-scale production runs of 10,000+ units.

2. How do you handle intellectual property (IP) and design confidentiality?

We take IP very seriously. We are happy to sign Non-Disclosure Agreements (NDAs) before you share any CAD files, and our internal servers are secured to prevent unauthorized access to your designs.

3. What is the standard tolerance Zeometrix can achieve?

Our standard machining tolerance is ISO 2768-m (medium). However, for critical features, we can achieve tolerances as tight as $\pm 0.005$ mm depending on the geometry and material.

4. How does Zeometrix compare in pricing to other Bangalore-based shops?

While we may not always be the "cheapest" in terms of raw hourly rate, we provide the best value. Our DfM feedback reduces waste, and our quality control eliminates the cost of rework or failed parts, saving you money in the long run.

5. Do you offer assembly services along with CNC machining?

Yes. We provide sub-assembly services, including the installation of helicoils, press-fit bearings, and combining multiple machined parts into a finished sub-unit.