From Concept to Component: Reliable CNC Machining Solutions in Bangalore

Introduction

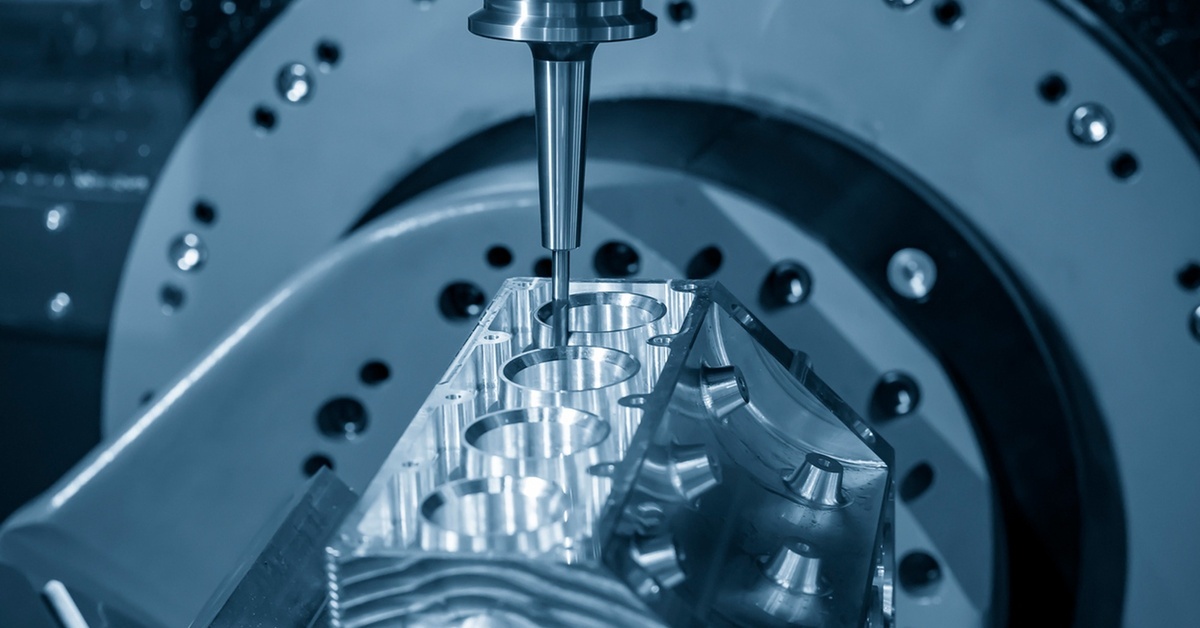

In the world of modern manufacturing, precision is power. Every component — from the tiniest gear to the most complex aerospace bracket — begins as an idea. Transforming that idea into a tangible, high-performance part requires not only advanced machinery but also expertise, consistency, and trust.

That’s exactly what Zeometrix, a leading CNC machining company in Bangalore, delivers. We specialise in taking your design concepts and turning them into production-ready components with unmatched accuracy, speed, and reliability. From prototype development to large-scale production, Zeometrix is your one-stop destination for reliable CNC machining in Bangalore, offering precision-engineered parts that meet international quality standards and exceed customer expectations.

Why Bangalore Is India’s CNC Machining Hub

Known as the “Silicon Valley of India,” Bangalore has evolved into a global centre for engineering and precision manufacturing. But what makes it so ideal for CNC machining?

1. Skilled Workforce and Engineering Expertise

Bangalore houses thousands of engineers trained in CAD/CAM, CNC programming, and design optimisation. This talent pool ensures that projects are executed with technical accuracy and innovative problem-solving.

2. Strong Industrial Ecosystem

Industrial areas like Peenya, Bommasandra, Jigani, and Electronic City have created a network of suppliers, metal finishing units, and logistics providers. This ecosystem enables faster turnaround times, seamless procurement, and reliable deliveries.

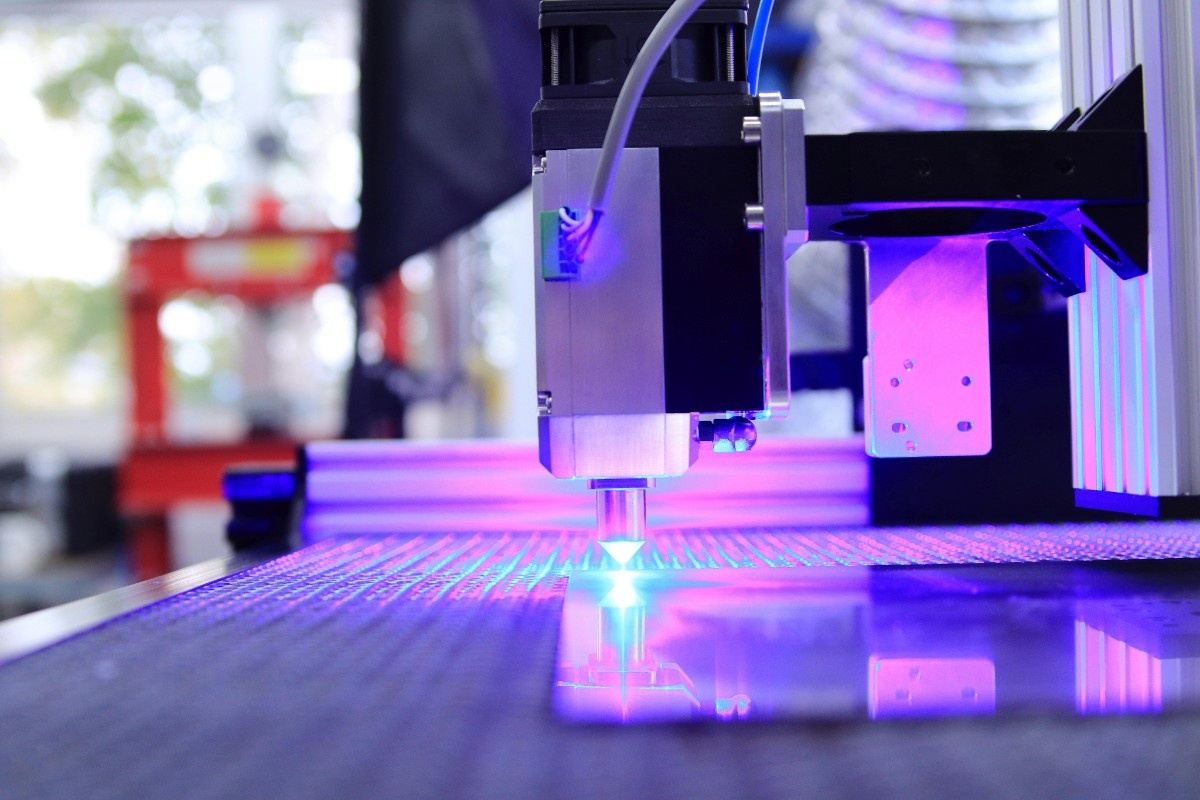

3. Focus on Quality and Technology

Most precision manufacturers in Bangalore, including Zeometrix, follow ISO 9001:2015 quality systems, use multi-axis CNC machines, and integrate digital inspection tools — ensuring each part meets global quality standards.

Zeometrix: Turning Concepts into Components

At Zeometrix, we believe every project has a story. Whether it’s a new product prototype or a batch production run, we’re committed to helping clients navigate the entire journey — from concept design to final delivery.

Here’s how we do it step-by-step:

1. Design Collaboration & Concept Validation

Our process begins with understanding your idea. You share your CAD model or drawing, and our design engineers review it for manufacturability, material selection, and cost optimisation.

We often suggest design modifications to improve functionality or reduce machining complexity — saving both time and money.

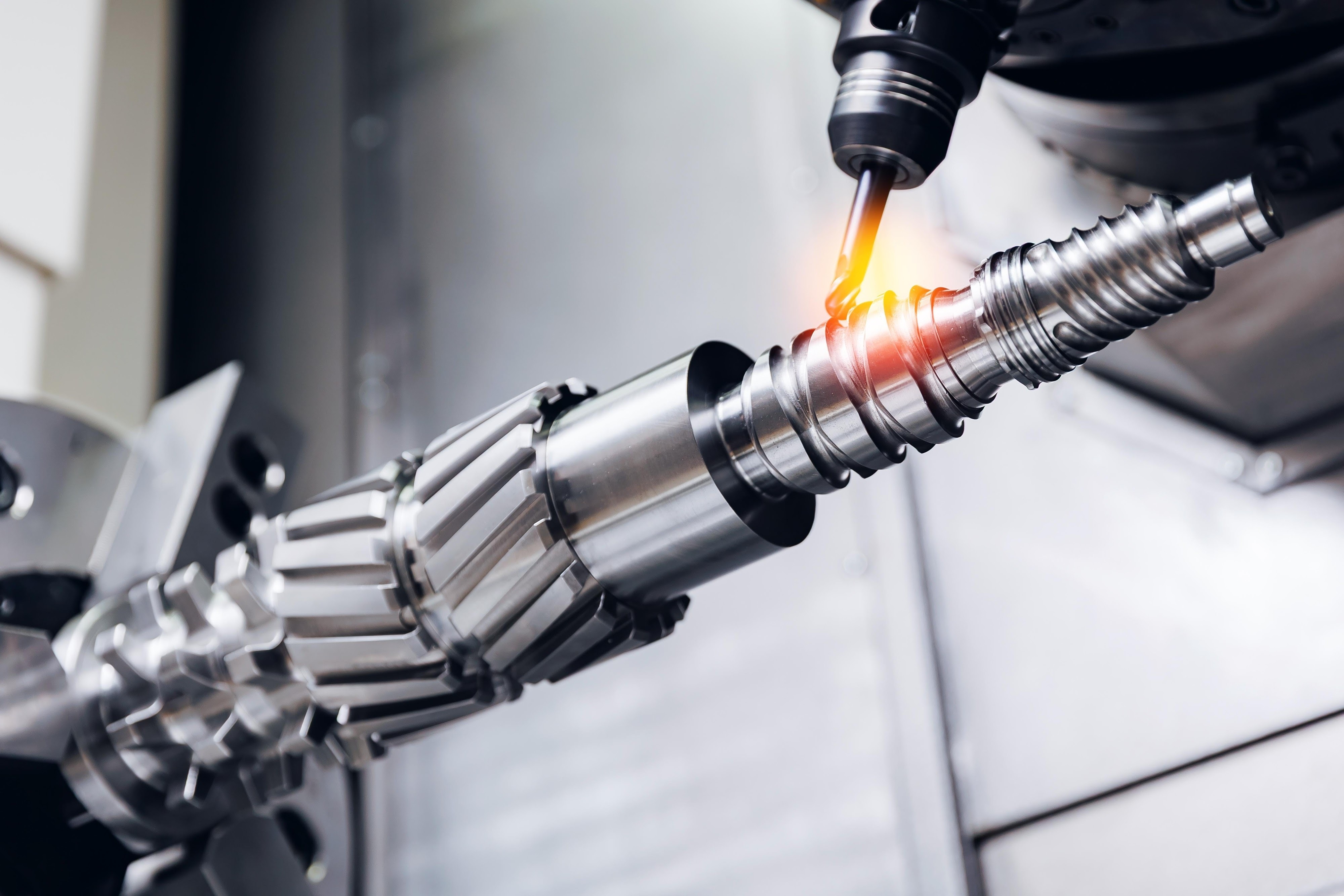

2. Rapid Prototyping for Faster Iteration

Prototyping is a critical phase in any product development cycle.

At Zeometrix, we use 3-axis, 4-axis, and 5-axis CNC machines to quickly produce prototypes that help you test design accuracy and performance.

Our rapid turnaround ensures your product reaches the testing stage sooner, shortening your overall time-to-market — a key advantage for startups and R&D teams in Bangalore’s competitive tech environment.

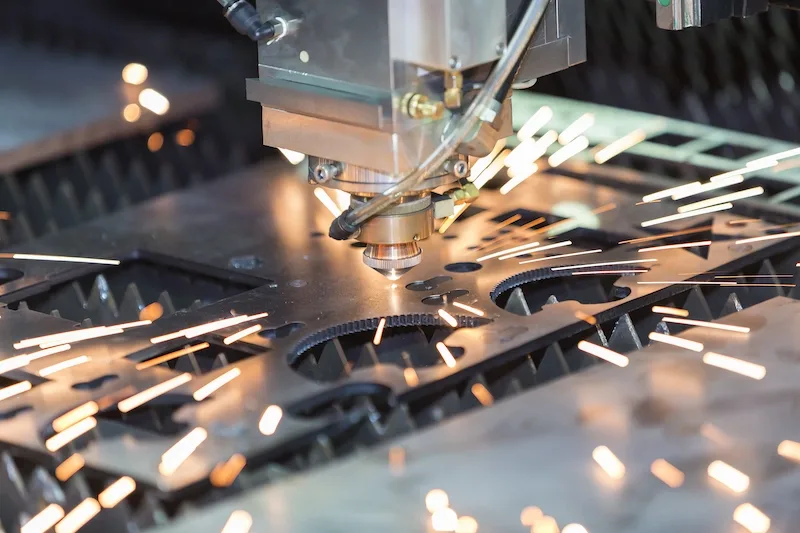

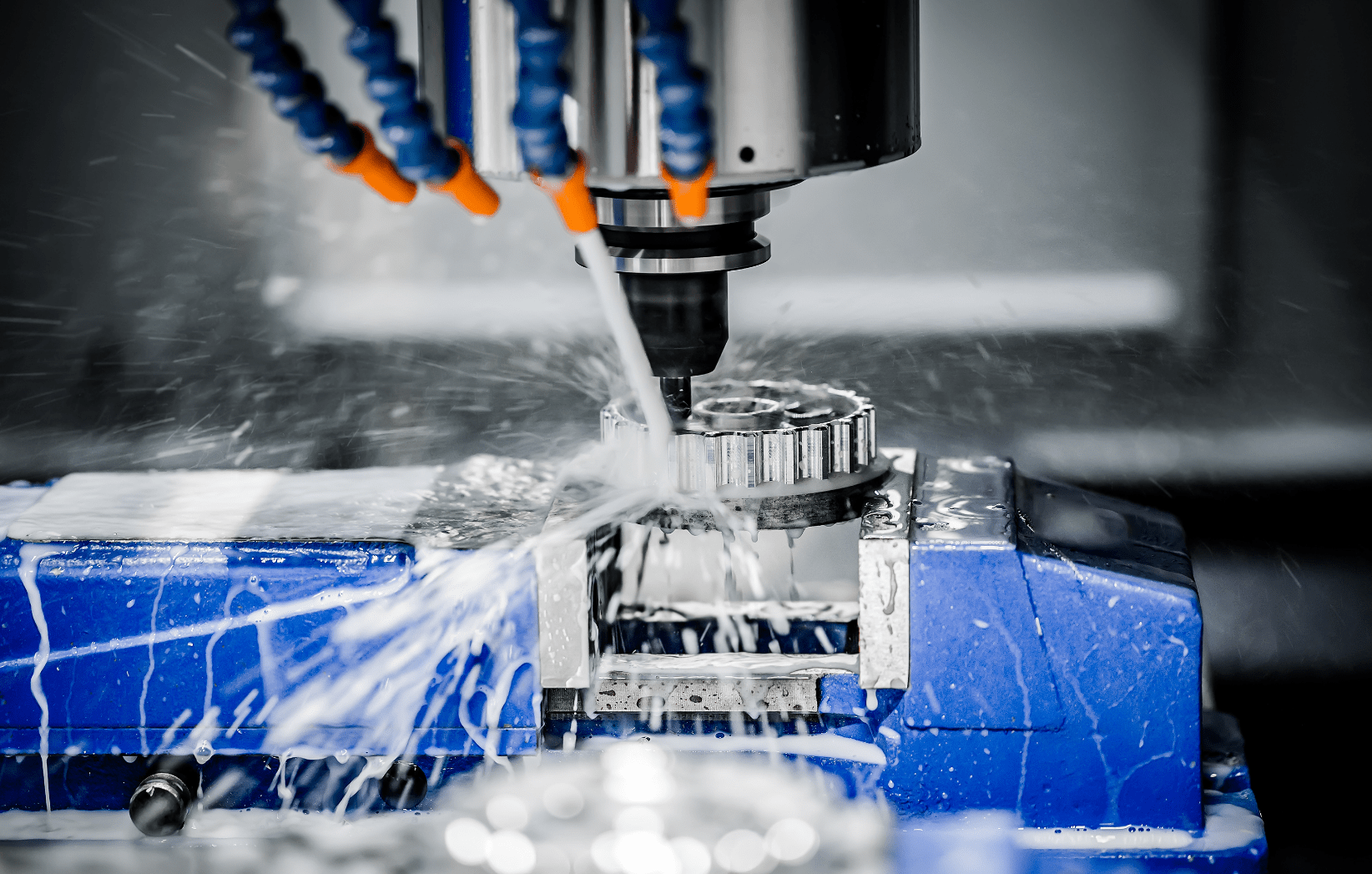

3. Precision Machining to Global Standards

Once the prototype is approved, we move to production. Our machining centres maintain micron-level tolerances and consistent repeatability.

From aerospace components to automotive housings, each part is produced with precision, inspected for quality, and verified against drawings using CMM (Coordinate Measuring Machines) and digital tools.

4. Material Versatility & Surface Finishing

Zeometrix machines components from a wide range of materials, including:

- Aluminium (6061, 7075, etc.)

- Stainless Steel (SS304, SS316)

- Brass, Copper, and Titanium

- Engineering Plastics (Delrin, Nylon, PEEK)

We also handle surface treatments like anodising, plating, bead blasting, powder coating, and polishing, ensuring the final part meets your performance and aesthetic requirements.

5. Scalable Production & Supply Chain Integration

When your prototype becomes a success, we help scale it up.

Zeometrix’s facility in Bangalore is strategically connected to local suppliers, logistics providers, and finishing partners, allowing us to handle small-batch as well as bulk manufacturing efficiently while delivering world-class CNC machining services to clients across diverse industries.

Our transparent project tracking and quality documentation ensure you stay informed at every stage.

6. Quality Control & Certification

For us, quality is not an inspection step — it’s part of the process.

Each project undergoes:

- In-process inspection

- Final dimensional verification

- Batch traceability

- Full inspection reports

We are committed to delivering precision components that meet international standards for industries like aerospace, automotive, medical, and defence.

Industries We Serve

Zeometrix provides CNC machining services across multiple industries:

Aerospace & Defence

Lightweight yet strong components, brackets, and housings machined to tight tolerances and certified for critical applications.

Automotive & Electric Vehicles (EV)

High-precision components for engines, transmissions, and EV battery assemblies.

Medical Devices

Surgical instruments, implantable parts, and precision assemblies machined with biocompatible materials.

Robotics & Industrial Automation

CNC-machined robot arms, actuators, and fixture components for high-precision automation setups.

Electronics & Semiconductor

Enclosures, heat sinks, and micro-components requiring complex geometries and fine surface finishes.

Why Choose Zeometrix for CNC Machining in Bangalore?

With so many options available, why do clients repeatedly choose Zeometrix?

- End-to-End Service – From concept design and prototyping to mass production and finishing, everything happens under one roof.

- Cutting-Edge Technology – Multi-axis CNC machines, precision measuring systems, and CAD/CAM integration.

- Experienced Team – Engineers with years of experience in mechanical design, manufacturing, and process optimisation.

- Competitive Pricing – Optimised operations ensure cost-effective yet high-quality output.

- On-Time Delivery – Streamlined supply chain management and agile production processes.

- Customer-Centric Approach – Transparent communication, real-time project tracking, and dedicated support.

Case Example: From Idea to Production

A Bangalore-based robotics startup approached Zeometrix with a CAD model for a custom robotic arm housing.

They needed:

- High-strength aluminium

- ±0.02 mm tolerance

- Black anodised finish

- 300 units within 30 days

Our engineers optimised the design for machinability, created prototypes in one week, and after approval, completed full production on schedule.

The result: precise components, consistent finish, and a satisfied client ready to launch their new product.

Conclusion

From the moment an idea is sketched on paper to the day the final part rolls out of the factory, precision machining defines success. At Zeometrix, we don’t just produce components — we create confidence.

With state-of-the-art CNC technology, skilled engineers, and a commitment to quality, we ensure every concept becomes a reality with unmatched precision and speed.

If you’re looking for reliable CNC machining solutions in Bangalore, Zeometrix is your trusted partner — from concept to component.

Frequently Asked Questions (FAQs)

1. What makes Zeometrix different from other CNC machining companies in Bangalore?

Zeometrix stands out for its end-to-end services — from design validation and prototyping to large-scale production — along with ISO-certified quality systems and industry-grade equipment.

2. Can Zeometrix handle both small and large production runs?

Absolutely. We specialise in both one-off prototypes and full-scale manufacturing batches. Our scalable production system adapts to your volume and timeline needs.

3. Which materials can Zeometrix machine?

We work with aluminium, stainless steel, titanium, brass, copper, and engineering plastics like Delrin and Nylon. Custom materials can also be sourced upon request.

4. How does Zeometrix ensure quality in CNC machining?

Our process includes in-process inspections, digital measurement, and CMM verification. Every batch is documented for full traceability and delivered with inspection reports.

5. How can I get a quote for my CNC machining project?

Simply share your CAD file or 2D drawing with details such as material, quantity, and tolerances at www.zeometrix.com or email us directly. Our team will respond with a detailed quotation within 24 hours.