Engineering at Micron Precision: Zeometrix and the Rise of Advanced CNC Machining in Bangalore

In the global landscape of precision engineering, Bangalore has carved out a reputation that rivals major manufacturing hubs in Germany, Japan, and the United States. While the city is widely celebrated as India’s Silicon Valley, its manufacturing core is equally impressive. Today, CNC machining in Bangalore has evolved into a high-tech powerhouse, serving as the backbone for aerospace, defense, medical, and automotive sectors.

At the forefront of this industrial transformation is Zeometrix. By integrating advanced robotics, high-speed machining, and a digital-first workflow, Zeometrix isn't just a service provider; it is an essential partner for companies looking to bridge the gap between complex digital designs and high-precision physical reality.

1. The Strategic Significance of Bangalore’s Manufacturing Ecosystem

The rise of Bangalore as a global hub for CNC machining is the result of a unique "Industrial Cluster" model. Unlike isolated factories in other regions, Bangalore’s manufacturing is concentrated in specialized zones like Peenya, Electronic City, and Bommasandra.

The Talent Density and Engineering Heritage

Bangalore houses the Indian Institute of Science (IISc) and a vast network of premier engineering colleges. This creates a "talent density" that is unmatched in the region. At Zeometrix, our workforce consists of more than just machine operators; we employ mechanical engineers and CNC programmers who understand the physics of chip formation, thermal expansion, and material fatigue. This high level of expertise allows us to tackle "impossible" geometries that other shops might turn away.

Proximity to Strategic Giants

The presence of public sector giants like HAL (Hindustan Aeronautics Limited), ISRO (Indian Space Research Organisation), and DRDO has forced the local CNC industry to adopt international standards of precision. To work with these entities, companies must maintain tolerances of $\pm 0.005$ mm and strictly adhere to AS9100 quality standards. Zeometrix brings this "space-grade" precision to every commercial project we undertake.

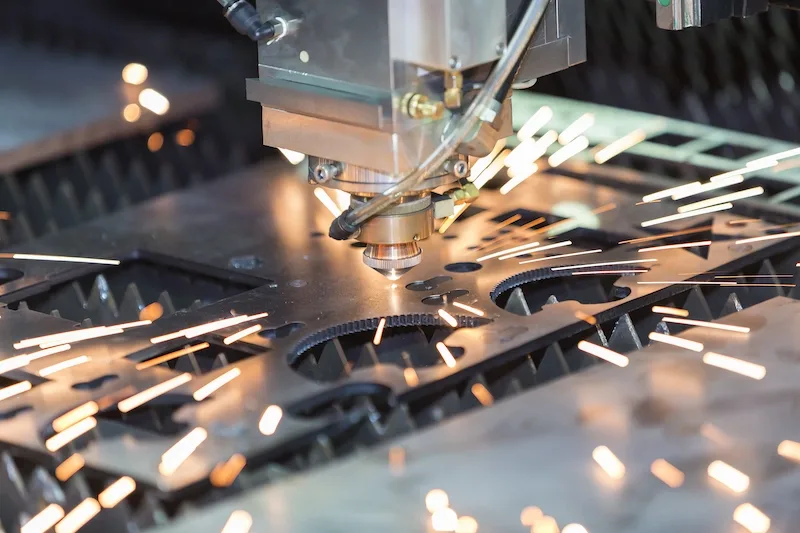

2. Technical Deep-Dive: The Zeometrix Machining Portfolio

CNC (Computer Numerical Control) machining is a subtractive process that relies on software to guide cutting tools. However, the quality of the output depends heavily on the machine's axis capabilities and the programmer’s skill.

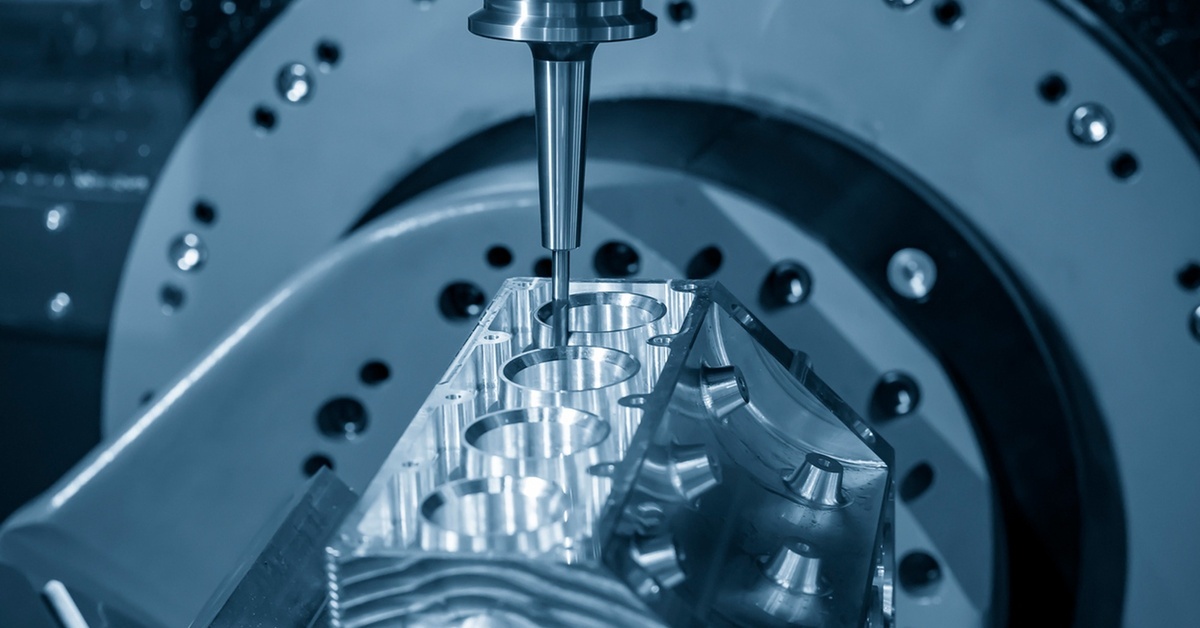

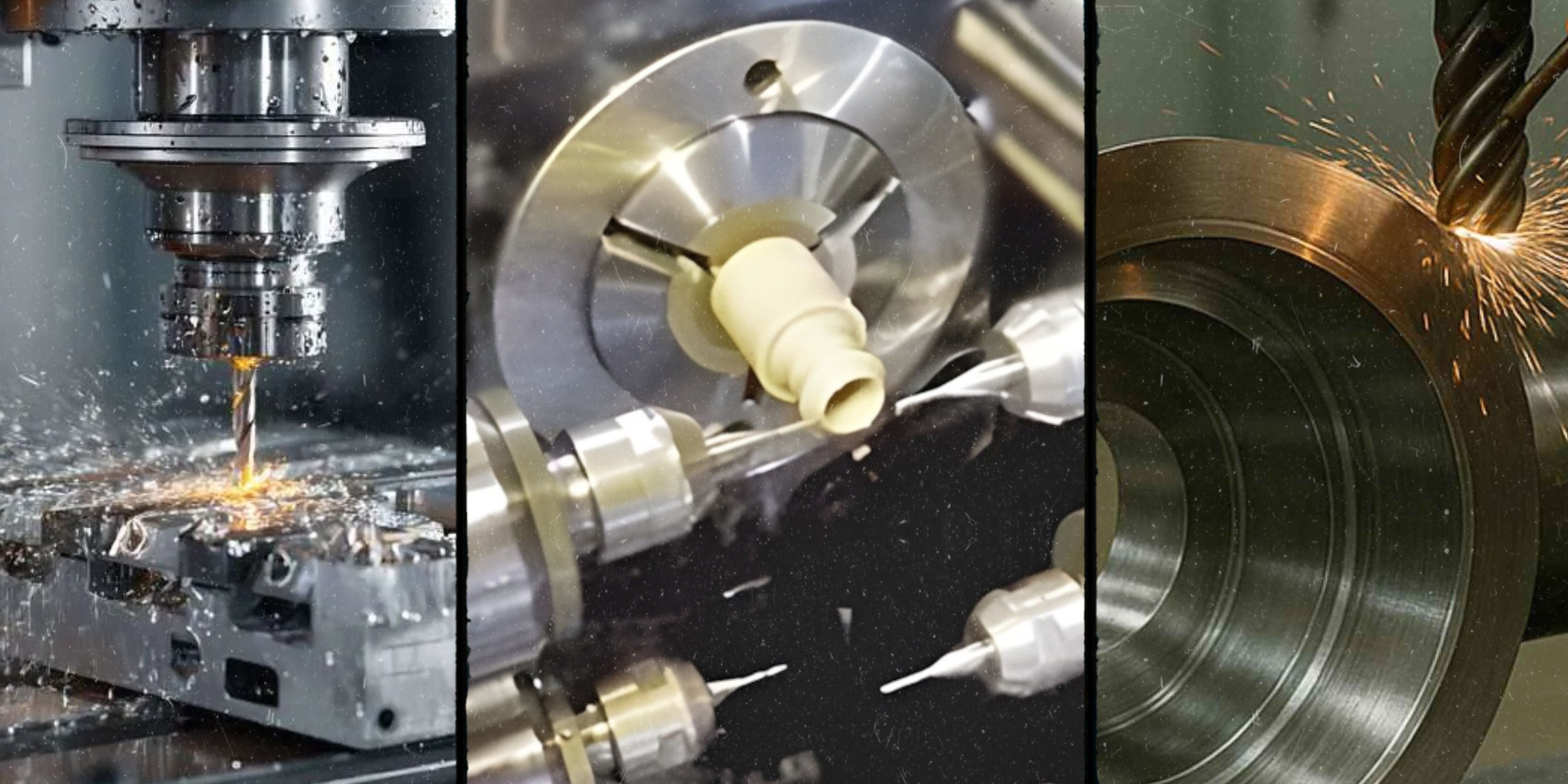

Advanced 5-Axis Milling

While standard 3-axis machines move along X, Y, and Z planes, our 5-axis CNC milling centers can rotate the cutting tool or the workpiece across two additional axes.

-

Complex Contours: Essential for aerospace impellers and organic medical shapes.

-

Single-Setup Accuracy: By machining five sides of a part in one go, we eliminate the errors that occur when a part is manually re-positioned (fixturing errors).

-

Superior Surface Finish: The ability to keep the tool at an optimal angle to the surface results in a smoother finish, often reducing the need for manual polishing.

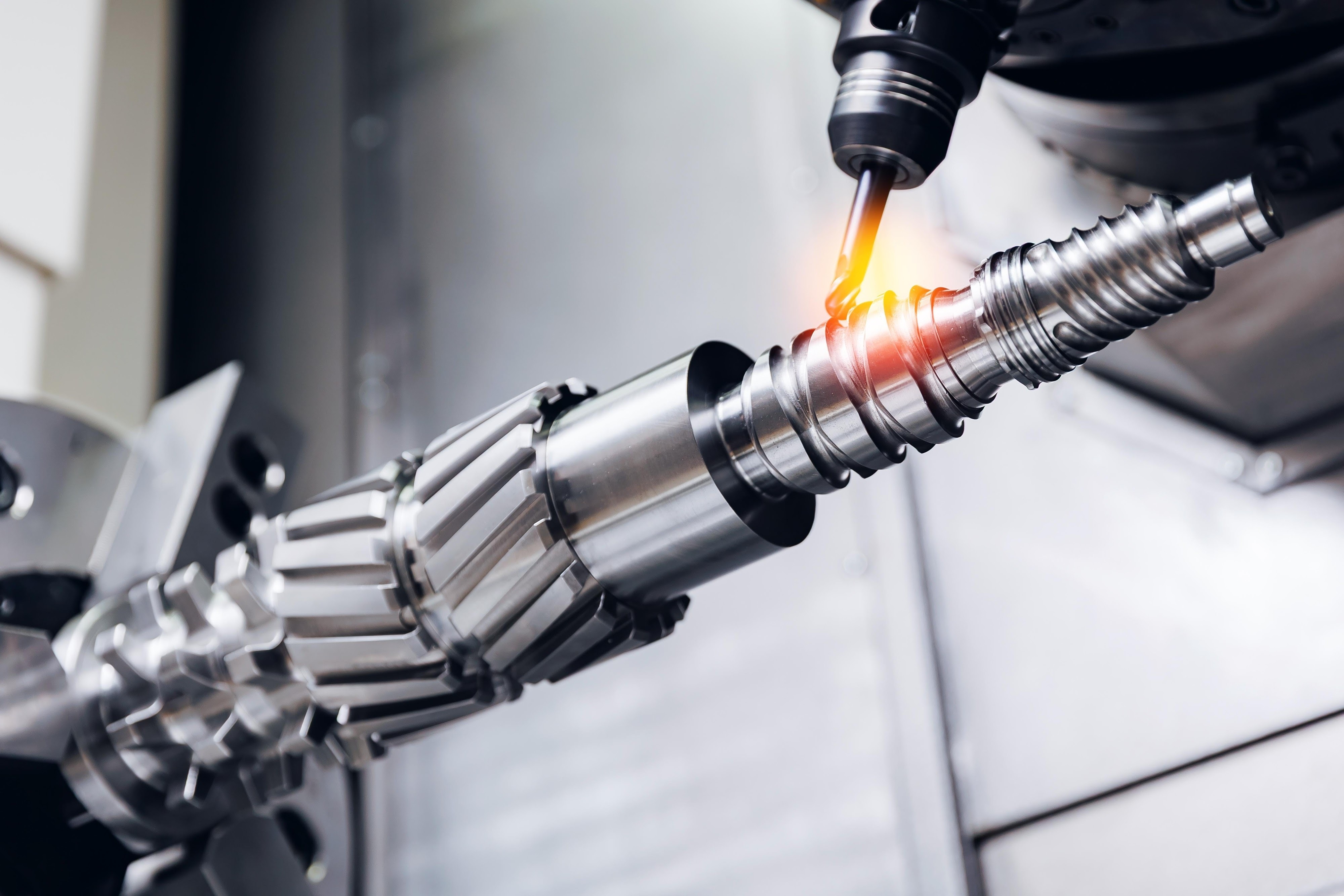

Precision CNC Turning and Swiss Lathes

For cylindrical parts like shafts, bushings, and custom fasteners, our CNC turning centers offer high-speed rotation and micron-level accuracy. Our machines often feature "live tooling," which allows us to perform milling operations (like drilling a side hole or cutting a slot) while the part is still spinning, ensuring perfect concentricity.

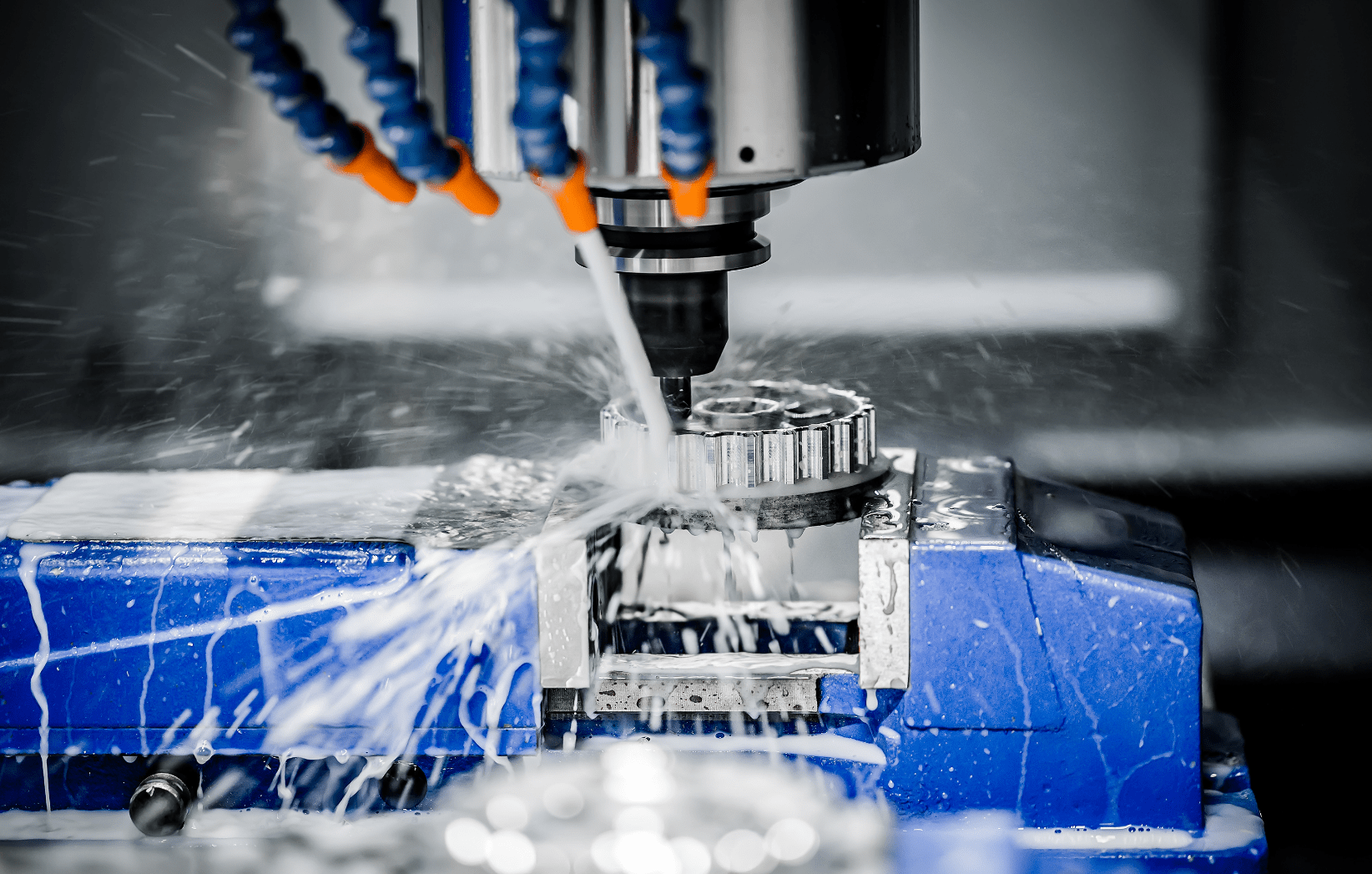

3. Mastering Materials: The Science of Selection

In the world of CNC machining in Bangalore, material selection is where the engineering rubber meets the road. Zeometrix works with a diverse range of materials, each requiring specific spindle speeds, feed rates, and coolant strategies.

Aerospace Metals: Aluminum 7075 and Titanium

Aluminum 7075-T6 is the "zinc-alloyed" king of the aerospace world, offering strength comparable to steel but at a fraction of the weight. Titanium Grade 5 (Ti-6Al-4V) is another specialty at Zeometrix, favored for its biocompatibility and extreme heat resistance, though it requires specialized diamond-coated tools to machine effectively.

Industrial Plastics: PEEK and Delrin

Many of our clients in the medical and semiconductor industries require non-conductive, chemically resistant parts. PEEK (Polyetheretherketone) is a high-performance thermoplastic that can withstand high temperatures and remains dimensionally stable under stress. Zeometrix ensures that plastic parts are machined with sharp tools to prevent melting or warping.

Exotic Superalloys: Inconel and Cobalt-Chrome

For high-heat environments like jet engines or industrial furnaces, we machine Inconel. These "superalloys" are notoriously difficult to cut because they work-harden rapidly. Our advanced CAM strategies at Zeometrix use "trochoidal milling" to manage heat and extend tool life.

4. Industry Applications: Powering Innovation

Aerospace and UAVs (Drones)

Bangalore is the drone capital of India. Zeometrix supports this industry by machining lightweight airframes, motor mounts, and gimbal components. Every gram saved in machining is a gram added to the drone’s payload or battery life.

Medical and Surgical Instruments

Precision is non-negotiable in healthcare. We produce surgical-grade stainless steel tools and diagnostic equipment housings. Our post-processing includes ultrasonic cleaning to ensure that no microscopic metal chips remain on the part.

Robotics and Industrial Automation

The "New Age" of Bangalore involves robots. We manufacture high-torque gears, robotic arm segments, and custom sensor housings. Our ability to prototype quickly allows robotics companies to iterate their designs in days rather than months.

5. The Digital Thread: From CAD to Component

What sets Zeometrix apart from a traditional “job shop” is our integration of the digital thread. When you search for custom CNC services, you want a partner who speaks the language of modern design and precision manufacturing.

Design for Manufacturability (DFM)

The moment you upload your STEP or IGES file, our engineers perform a DFM analysis. We look for "un-machinable" features, such as:

-

Internal Sharp Corners: We suggest adding fillets to accommodate round cutting tools.

-

Deep, Narrow Cavities: We advise on depth-to-width ratios to prevent tool vibration (chatter).

-

Overly Tight Tolerances: We identify where a looser tolerance can significantly lower your production cost without affecting part function.

Cloud-Based Project Management

Zeometrix utilizes a transparent tracking system. Clients can see exactly which stage their parts are in—from material procurement and programming to machining, inspection, and shipping.

6. Post-Processing: The Finishing Touch

Machining is often just the first step. To survive in harsh environments, parts need surface treatments. Zeometrix offers an integrated supply chain for:

-

Anodizing (Type II & III): For corrosion resistance and color.

-

Bead Blasting: To remove tool marks and create a uniform matte finish.

-

Passivation: Essential for stainless steel in medical applications.

-

Powder Coating: For durable, aesthetic exterior finishes.

7. The Global Shift: Why Bangalore is the Preferred Choice

As companies adopt the "China Plus One" strategy, Bangalore has emerged as the premier alternative for high-precision manufacturing.

-

Cost Advantage: Significant savings on labor and overhead compared to Western shops.

-

English Proficiency: Technical specifications and nuances are communicated clearly, preventing costly errors.

-

Time Zone Advantage: For US-based clients, the 10.5 to 12.5-hour time difference allows for a "follow-the-sun" model where designs sent in the evening are reviewed or machined by the next morning.

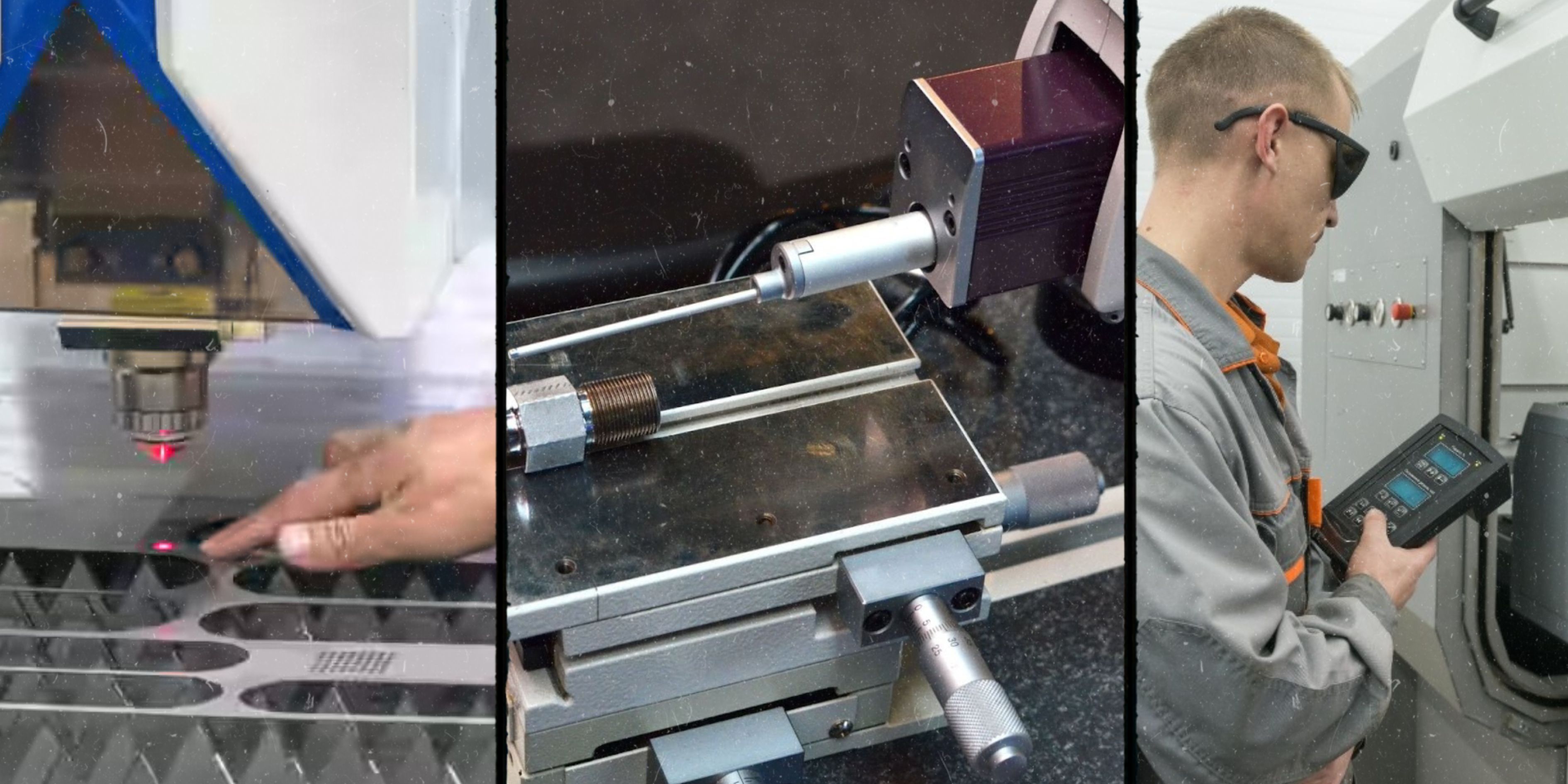

8. Quality Control: The Zeometrix Guarantee

"Precision" at Zeometrix is verified by data. Our quality lab is the heart of our facility.

-

Coordinate Measuring Machine (CMM): Used to verify the physical dimensions of a part against its digital twin.

-

Surface Profilometers: To measure the $R_a$ (roughness average) of a surface, ensuring it meets friction or aesthetic requirements.

-

Material Traceability: We provide full material certifications (MTRs) to prove that the metal we used is exactly what was specified in your order.

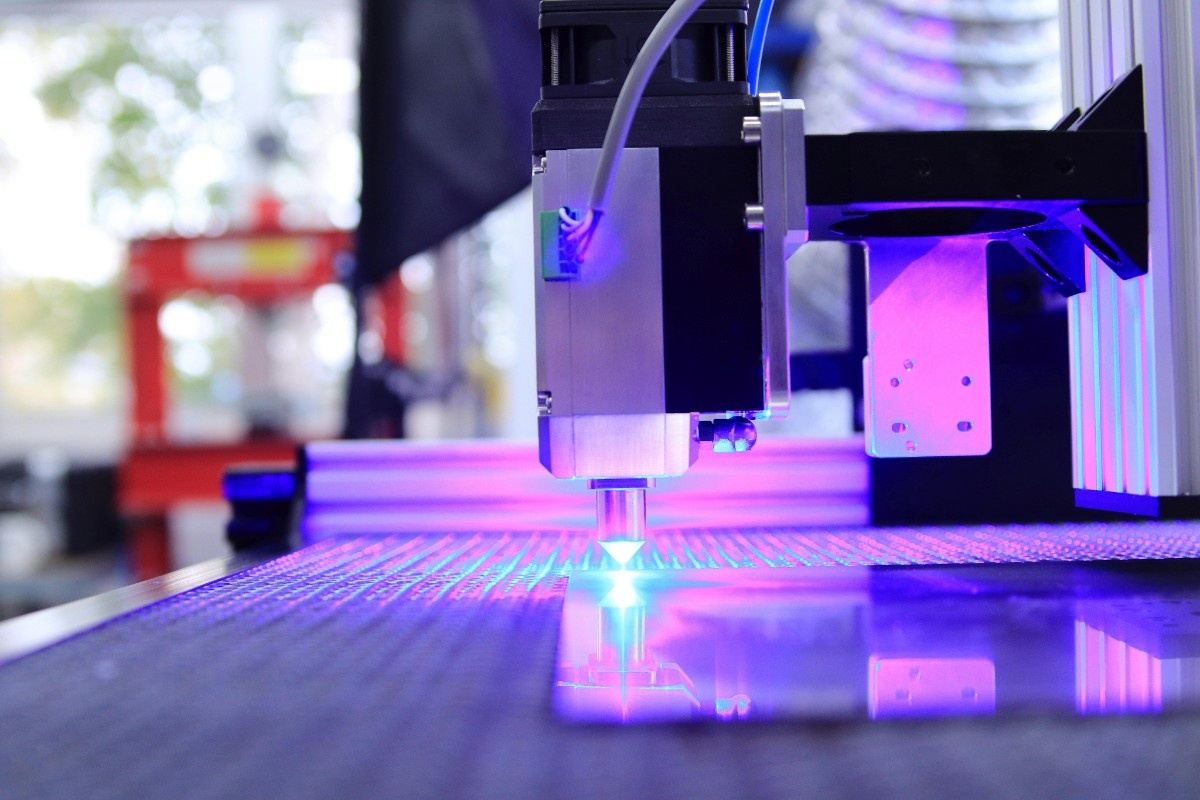

9. The Future of CNC: Industry 4.0 and Zeometrix

The future of CNC machining in Bangalore lies in automation. Zeometrix is currently integrating IoT sensors on our machines to monitor tool wear in real-time. This "predictive maintenance" ensures that a tool never fails mid-cut, protecting your expensive raw materials and ensuring consistent quality across large batches.

10. Conclusion: Partner with the Best

Bangalore is no longer just a destination for software; it is a global beacon for precision hardware. By combining the city’s rich engineering heritage with modern, data-driven workflows, Zeometrix provides a manufacturing experience that is fast, reliable, and exceptionally accurate.

Whether you are an engineer at a Fortune 500 company or a founder of a hardware startup, Zeometrix has the capacity and the technical depth to bring your vision to life. From the first prototype to a production run of thousands, we are committed to being the best provider of CNC machining in Bangalore.

Frequently Asked Questions (FAQ)

1. What is the typical lead time for a CNC project at Zeometrix?

For standard rapid prototyping, our lead time is 3 to 7 business days. For production batches (100+ units), the lead time usually ranges between 2 to 4 weeks, depending on material availability and the complexity of post-processing like anodizing or heat treatment.

2. Can Zeometrix handle "impossible" parts with very tight tolerances?

Yes. Using our 5-axis machining centers and climate-controlled facility, we can achieve tolerances as tight as $\pm 0.005$ mm ($0.0002''$). However, such tolerances should only be specified for critical mating surfaces to keep production costs efficient.

3. Which industries does Zeometrix primarily serve?

We are a multi-sector partner. Our primary clients are in Aerospace, Defense, Medical Devices, Robotics, and EV (Electric Vehicle) manufacturing. We are also a preferred partner for semiconductor equipment manufacturers who require high-purity material machining.

4. Do you provide material certifications and inspection reports?

Absolutely. Quality is a data-driven process at Zeometrix. Every shipment can be accompanied by a Material Test Report (MTR) and a Certificate of Conformance (CoC). For high-precision parts, we also provide full CMM Inspection Reports.

5. What file formats should I use to get a quote?

The best format for our automated analysis is a STEP (.stp or .step) or IGES (.igs) file. For parts with specific tolerances, threading, or surface finish requirements, please also include a 2D PDF drawing with all the technical callouts clearly marked.